Feeling lost in a sea of interview questions? Landed that dream interview for Edge Burnisher but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Edge Burnisher interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

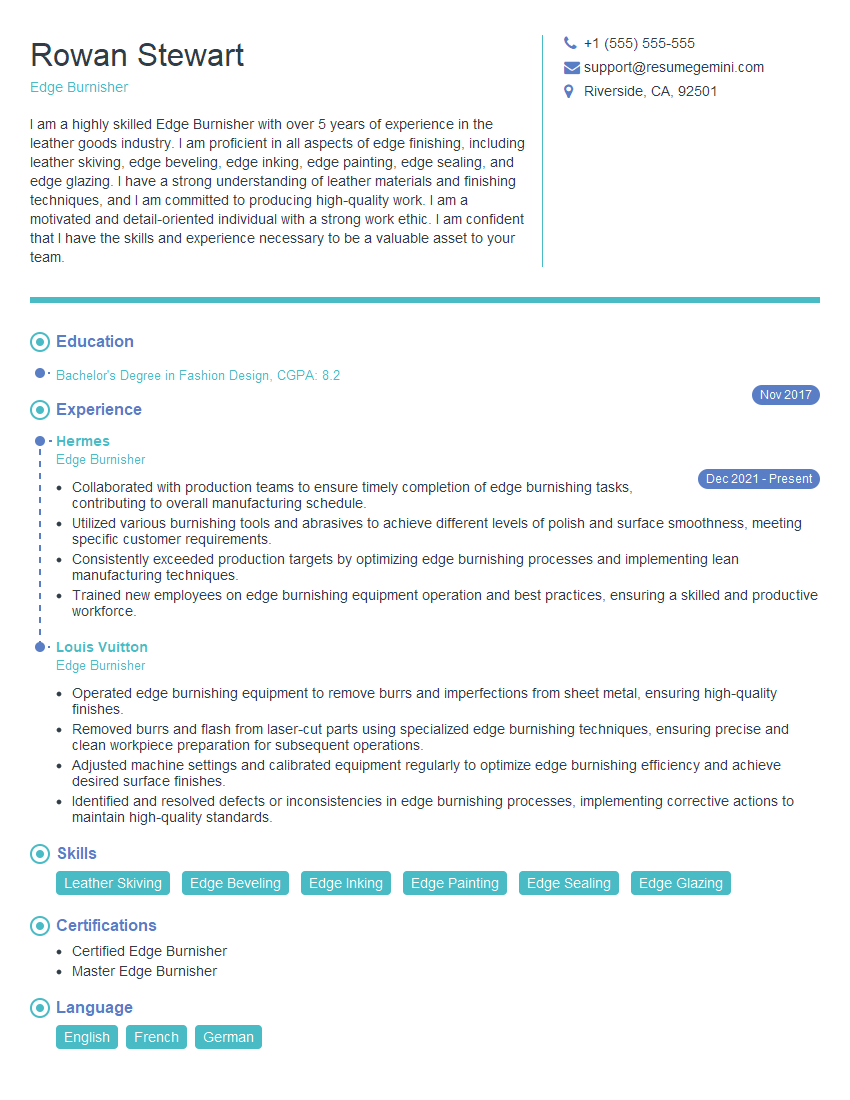

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Edge Burnisher

1. What are the key performance indicators (KPIs) that you have used to measure the effectiveness of your edge burnishing process?

The KPIs that I have used to measure the effectiveness of my edge burnishing process are:

- Surface finish

- Edge radius

- Cycle time

- Tool life

2. How do you ensure that the edge burnishing process is repeatable and reliable?

Process Control

- I use a standardized process that is documented and followed by all operators.

- I have implemented a quality control system that includes regular inspections and testing.

Equipment Maintenance

- I ensure that the equipment is properly maintained and calibrated.

- I replace worn or damaged tools and components promptly.

3. What are the different types of edge burnishing tools and how do you select the appropriate tool for each application?

The different types of edge burnishing tools include:

- Fixed abrasive tools

- Rotary abrasive tools

- Oscillating abrasive tools

I select the appropriate tool based on the following factors:

- The material of the workpiece

- The desired surface finish

- The edge geometry

- The production volume

4. How do you troubleshoot common edge burnishing problems, such as chatter, burrs, and uneven surface finish?

- Chatter: I check the tool for wear or damage. I also check the workpiece for proper clamping and support.

- Burrs: I reduce the feed rate or increase the spindle speed. I also check the tool for sharpness.

- Uneven surface finish: I check the tool for wear or damage. I also check the workpiece for proper clamping and support. I may also need to adjust the feed rate or spindle speed.

5. What are the safety precautions that must be taken when operating an edge burnishing machine?

- Wear appropriate personal protective equipment (PPE), such as safety glasses, gloves, and earplugs.

- Keep hands and clothing away from moving parts.

- Secure the workpiece properly.

- Follow the manufacturer’s operating instructions.

- Be aware of the hazards of flying debris.

6. How do you stay up-to-date on the latest edge burnishing technologies and best practices?

- I attend industry conferences and trade shows.

- I read trade publications and technical journals.

- I network with other edge burnishing professionals.

- I take online courses and webinars.

7. What are the advantages and disadvantages of edge burnishing compared to other edge finishing processes?

Advantages

- Increased surface hardness and wear resistance

- Improved fatigue strength

- Reduced stress concentrations

- Improved corrosion resistance

- Improved appearance

Disadvantages

- Can be more expensive than other edge finishing processes

- Can be more time-consuming than other edge finishing processes

- Not suitable for all materials

8. How do you calculate the cycle time for an edge burnishing process?

The cycle time for an edge burnishing process can be calculated using the following formula:

Cycle time = (Length of cut + Feed rate) / Spindle speed

Where:

- Length of cut is the distance that the tool travels along the edge

- Feed rate is the rate at which the tool moves along the edge

- Spindle speed is the speed at which the tool rotates

9. What are the different types of edge burnishing machines?

- Manual edge burnishing machines

- Semi-automatic edge burnishing machines

- Automatic edge burnishing machines

10. What are the key factors to consider when selecting an edge burnishing machine?

- The size and shape of the workpieces

- The desired surface finish

- The production volume

- The budget

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Edge Burnisher.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Edge Burnisher‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Edge Burnishers are responsible for smoothing and polishing the edges of various materials, such as leather, fabric, and plastic. They use specialized equipment to create a smooth, finished look on the edges of products.

1. Edge Smoothing

Using sanding tools or machines, edge burnishers smooth out rough edges of materials to prepare them for further processing.

- Select appropriate sanding tools or machines based on material type and desired finish.

- Operate sanding equipment safely and efficiently to remove excess material and create a smooth surface.

2. Edge Polishing

Employing polishing wheels, compounds, and techniques, edge burnishers enhance the appearance of edges by creating a glossy and refined finish.

- Determine the appropriate polishing compounds and techniques for different materials.

- Use polishing wheels and compounds to achieve desired sheen and smoothness on edges.

3. Edge Sealing

In order to protect and enhance the durability of edges, edge burnishers apply sealants or finishes.

- Select and apply appropriate sealants or finishes to protect edges from wear and tear.

- Ensure proper application techniques to achieve optimal results and prevent damage to materials.

4. Equipment Maintenance

To ensure the smooth functioning of edge burnishing operations, edge burnishers are responsible for maintaining and calibrating equipment.

- Perform regular maintenance and calibration of sanding machines, polishing wheels, and other equipment.

- Identify and troubleshoot any equipment issues to minimize downtime and maintain productivity.

Interview Tips

To help candidates ace their Edge Burnisher interview, here are some tips and preparation hacks:

1. Research the Company and Position

By researching the company and the specific position, candidates can demonstrate their interest and understanding of the role.

- Visit the company website to learn about their products, services, and culture.

- Review the job description thoroughly to identify the key responsibilities and qualifications required.

2. Prepare for Common Interview Questions

Anticipating common interview questions allows candidates to prepare thoughtful responses and showcase their skills and experience.

- Practice answering questions about their experience in edge burnishing, including techniques and equipment used.

- Prepare examples to demonstrate their attention to detail, problem-solving abilities, and commitment to quality.

3. Highlight Relevant Skills and Experience

Candidates should emphasize their relevant skills and experience that align with the job requirements.

- Showcase their proficiency in operating edge burnishing equipment and using various techniques.

- Highlight their understanding of different materials and their edge finishing requirements.

4. Demonstrate Professionalism and Enthusiasm

Interviewers are impressed by candidates who display professionalism and enthusiasm for the role.

- Dress appropriately and arrive on time for the interview.

- Maintain eye contact, speak clearly, and ask thoughtful questions to show engagement.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Edge Burnisher interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.