Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Electromechanical Equipment Assembler interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Electromechanical Equipment Assembler so you can tailor your answers to impress potential employers.

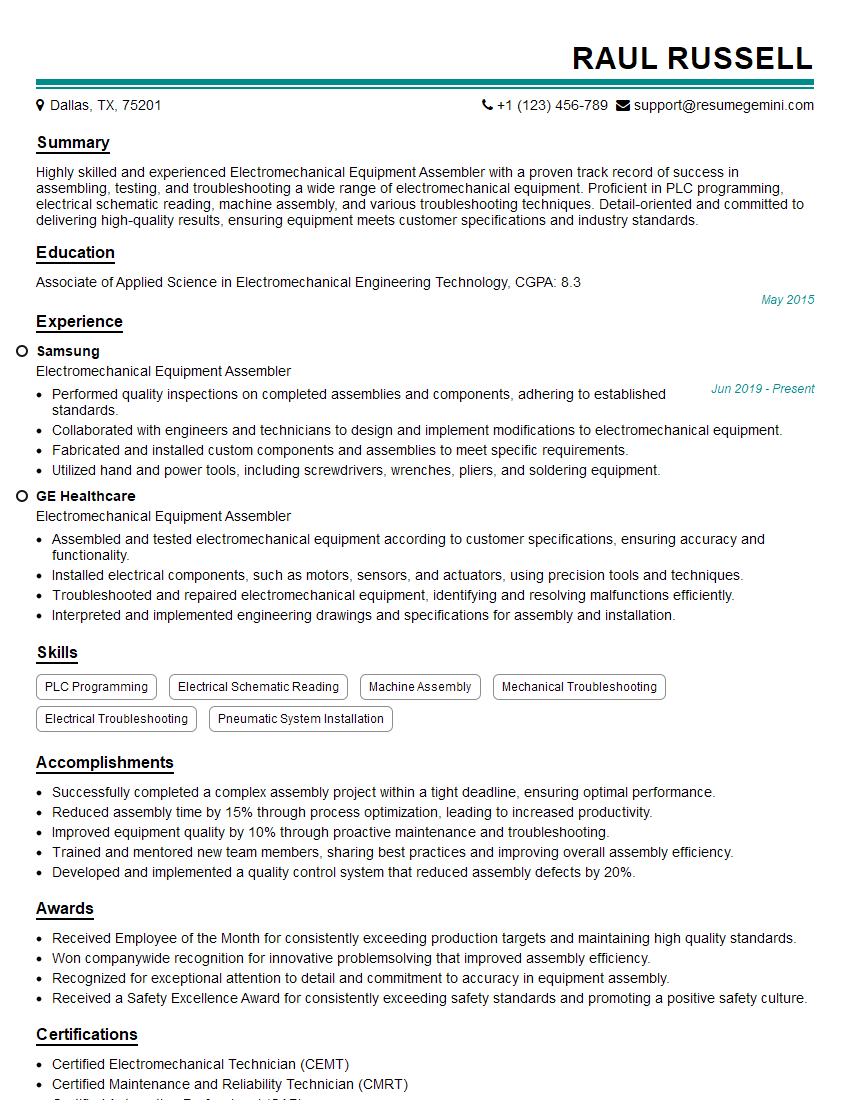

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Electromechanical Equipment Assembler

1. Describe the process of installing and wiring electrical components in an electromechanical assembly.

The process of installing and wiring electrical components in an electromechanical assembly involves several steps:

- Preparation: Read and understand assembly drawings and schematics, gather necessary tools and materials.

- Component Placement: Position electrical components such as motors, sensors, switches, and circuit boards according to the design.

- Wiring: Connect electrical components using wires, cables, and connectors. Follow wiring diagrams to ensure proper connections.

- Soldering: Join wires and components using solder to create permanent electrical connections.

- Testing: Perform continuity and insulation tests to verify the accuracy and functionality of the wiring.

2. Explain the principles of operation of a stepping motor and how it differs from a DC motor.

Stepping Motor Principles

- Consists of a stator with electromagnets and a rotor with permanent magnets.

- When an electromagnet is energized, it creates a magnetic field that aligns the rotor to a specific position.

- By energizing electromagnets in sequence, the rotor rotates in discrete steps.

DC Motor Principles

- Consists of a stator with electromagnets and a rotor with a wound armature.

- When the electromagnets are powered, they create a rotating magnetic field.

- The armature interacts with the rotating field, causing it to rotate continuously.

Key Differences

- Stepping motors rotate in discrete steps, while DC motors rotate continuously.

- Stepping motors have precise angular control, while DC motors offer variable speed control.

3. How do you troubleshoot common electrical faults in an electromechanical system?

To troubleshoot common electrical faults, follow these steps:

- Identify the Fault: Use diagnostic tools like multimeters and oscilloscopes to locate the fault.

- Check Power Supply: Ensure that the electromechanical system is receiving sufficient power.

- Examine Wiring: Inspect wires and cables for damage, loose connections, or short circuits.

- Test Components: Use continuity and insulation tests to check the functionality of electrical components.

- Repair or Replace: Once the fault is identified, repair or replace damaged components or wiring.

4. Describe the different types of encoders used in electromechanical systems and their applications.

- Incremental Encoder: Outputs pulses as the shaft rotates, indicating angular position.

- Absolute Encoder: Provides absolute position information in digital or analog format.

- Rotary Encoder: Converts shaft rotation into digital signals, representing angular displacement.

- Linear Encoder: Measures linear displacement along a straight path.

Applications

- Incremental encoders: Robotics, CNC machines.

- Absolute encoders: Industrial automation, medical devices.

- Rotary encoders: Position control, motion feedback.

- Linear encoders: Printers, scanners, packaging machinery.

5. How do you ensure the accuracy and precision of electromechanical assemblies?

To ensure accuracy and precision, follow these practices:

- Use Calibrated Tools: Use precision measuring tools and instruments to ensure accurate measurements.

- Follow Assembly Procedures: Adhere to established assembly procedures and guidelines to minimize errors.

- Inspect Assemblies: Perform thorough inspections at each stage of assembly to identify any defects or deviations.

- Calibrate and Test: Calibrate sensors and other components to maintain specified tolerances.

- Document Assembly: Maintain accurate documentation to ensure traceability and accountability.

6. Explain the importance of safety precautions when working with electromechanical equipment.

- Electrical Hazards: Prevent electric shock by wearing insulated gloves, using non-conductive tools, and isolating live wires.

- Mechanical Hazards: Avoid moving parts, use guards and shields, and secure equipment properly.

- Chemical Hazards: Be aware of potential chemical hazards associated with cleaning agents, solvents, and lubricants.

- Ergonomic Hazards: Take precautions to prevent repetitive motion injuries by using proper posture, tools, and ergonomic practices.

7. Describe the role of programmable logic controllers (PLCs) in electromechanical systems.

- Control Logic: PLCs execute control programs to automate system functions.

- Input/Output (I/O) Management: They monitor inputs (e.g., sensors) and control outputs (e.g., actuators).

- Data Acquisition and Storage: PLCs can collect and store data from sensors and devices.

- Communication: They facilitate communication with other systems and devices using industrial protocols.

8. How do you stay up-to-date with advancements in electromechanical technologies?

- Industry Publications: Read technical journals and industry magazines to learn about new technologies.

- Conferences and Webinars: Attend industry events to network and learn about emerging trends.

- Online Learning: Take online courses and participate in webinars to enhance knowledge and skills.

- Company Training: Seek opportunities for training and development offered by your employer.

9. Describe your experience in using diagnostic tools and software for electromechanical troubleshooting.

In my previous role, I used various diagnostic tools and software, including:

- Multimeters: Measured voltage, current, and resistance to diagnose electrical faults.

- Oscilloscopes: Analyzed electrical waveforms to identify signal distortions and timing issues.

- Logic Analyzers: Examined digital signals to troubleshoot logic circuits and bus protocols.

- Diagnostic Software: Utilized specialized software to diagnose and debug PLC programs.

10. Explain your understanding of industry standards and regulations related to electromechanical assembly.

- UL Standards: Familiar with UL standards (e.g., UL 508A) for electrical safety and compliance.

- IEC Standards: Aware of IEC standards (e.g., IEC 60204-1) for machine safety and risk assessment.

- OSHA Regulations: Understand OSHA regulations (e.g., 29 CFR 1910.303) concerning electrical safety in the workplace.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Electromechanical Equipment Assembler.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Electromechanical Equipment Assembler‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Electromechanical Equipment Assemblers are responsible for assembling, testing, and troubleshooting electromechanical equipment. They work with a variety of electrical and mechanical components, and must have a strong understanding of how these components work together. Some of the key job responsibilities of Electromechanical Equipment Assemblers include:

1. Assembling electromechanical equipment

Assemblers follow blueprints and schematics to assemble electromechanical equipment, such as motors, generators, and control panels. They use hand tools and power tools to connect electrical components, mechanical components, and wiring. They must ensure that all components are assembled correctly and securely, and that the equipment meets all specifications.

2. Testing electromechanical equipment

Once the equipment is assembled, assemblers test it to ensure that it is functioning properly. They use a variety of test equipment, such as multimeters, oscilloscopes, and power supplies. They check for electrical continuity, insulation resistance, and other parameters. They also run the equipment through a series of tests to ensure that it meets all specifications.

3. Troubleshooting electromechanical equipment

If the equipment does not meet specifications, assemblers troubleshoot the problem. They use their knowledge of electrical and mechanical components to identify the source of the problem. They then repair or replace the faulty components and retest the equipment. They must be able to quickly and accurately diagnose and repair problems in order to minimize downtime.

4. Maintaining electromechanical equipment

Assemblers also perform maintenance on electromechanical equipment. They clean and inspect the equipment, and replace worn or damaged parts. They also make adjustments to the equipment to ensure that it is operating at peak efficiency. They must be able to identify and correct potential problems before they become major issues.

Interview Tips

If you are preparing for an interview for an Electromechanical Equipment Assembler position, there are a few things you can do to improve your chances of success. Here are a few tips:

1. Research the company and the position

Before the interview, take some time to research the company and the position you are applying for. This will help you to understand the company’s culture and values, and the specific requirements of the position. You can find information about the company on their website, in press releases, and in articles about the company. You can also find information about the position in the job description.

2. Practice your answers to common interview questions

There are a few common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?”. It is helpful to practice your answers to these questions in advance so that you can deliver them confidently and concisely. You can also prepare for other questions that you may be asked, such as questions about your experience, skills, and qualifications.

3. Be prepared to talk about your experience and skills

In the interview, you will be asked to talk about your experience and skills. Be prepared to discuss your experience in assembling, testing, and troubleshooting electromechanical equipment. You should also be prepared to talk about your skills in electrical and mechanical engineering, as well as your ability to work independently and as part of a team.

4. Be prepared to answer questions about your knowledge of the industry

The interviewer may also ask you questions about your knowledge of the electromechanical equipment industry. Be prepared to discuss your understanding of the latest trends and technologies in the industry, as well as your knowledge of the specific equipment that the company manufactures.

5. Be prepared to ask questions

At the end of the interview, you will be given the opportunity to ask questions. This is a good opportunity to learn more about the company and the position, and to show the interviewer that you are interested and engaged. Some good questions to ask include: “What are the biggest challenges facing the company right now?” and “What are the opportunities for advancement within the company?”.

Next Step:

Now that you’re armed with the knowledge of Electromechanical Equipment Assembler interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Electromechanical Equipment Assembler positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini