Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Electrostatic Paint Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Electrostatic Paint Operator so you can tailor your answers to impress potential employers.

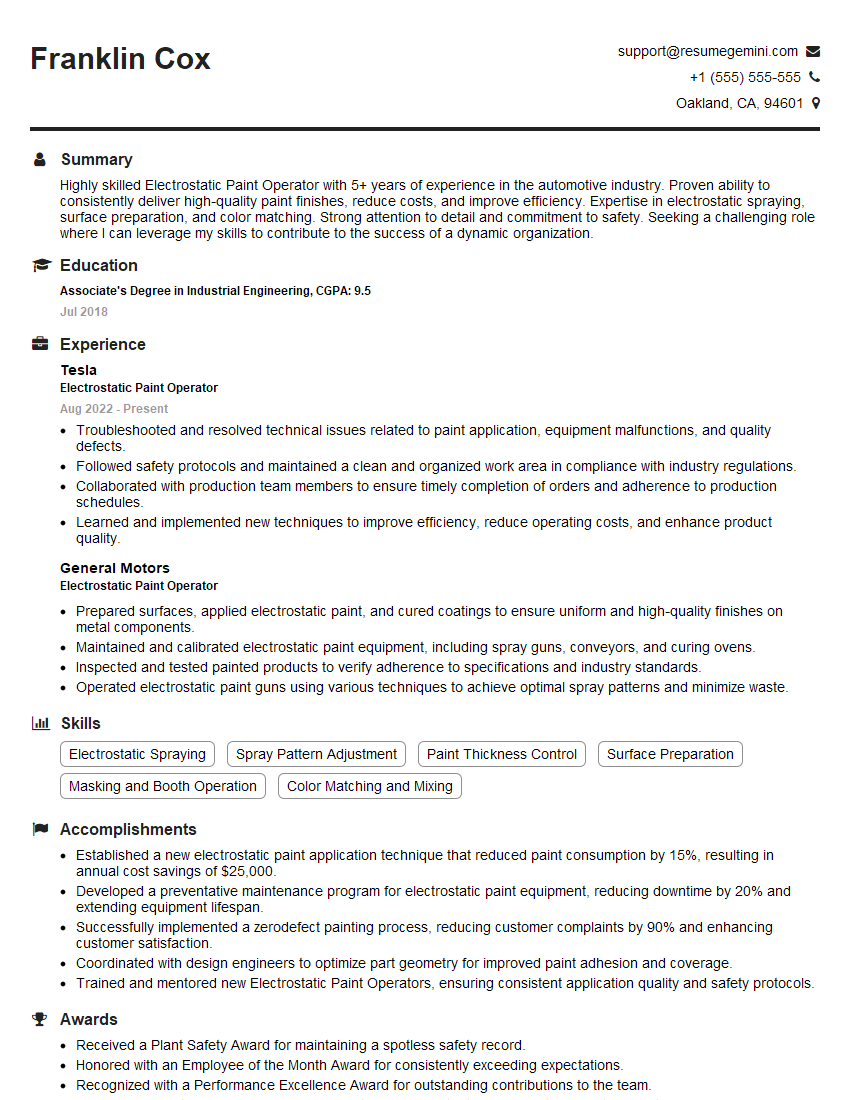

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Electrostatic Paint Operator

1. How do you ensure that the electrostatic paint is applied evenly to the surface?

To ensure even application of electrostatic paint, I follow these steps:

- Properly prepare the surface by cleaning and removing any contaminants to create a smooth and receptive surface.

- Adjust the spray gun settings, including the voltage and air pressure, to optimize the paint flow and atomization.

- Maintain a consistent distance between the spray gun and the surface, typically between 6-12 inches, to achieve a uniform coating thickness.

- Move the spray gun in a smooth and controlled manner, overlapping each pass slightly to avoid missed or uneven areas.

- Regularly inspect the painted surface to identify any defects or imperfections and address them promptly.

2. How do you determine the correct viscosity of the paint for electrostatic application?

Measuring Viscosity

- Use a viscometer, such as a Zahn cup or a Brookfield viscometer, to measure the viscosity of the paint.

- Compare the measured viscosity to the manufacturer’s specifications or industry standards for electrostatic painting.

Adjusting Viscosity

- If the viscosity is too high, add a compatible thinner or solvent to reduce the thickness and improve flow.

- If the viscosity is too low, add a thickener or a higher viscosity paint to increase the thickness and prevent excessive dripping.

3. How do you troubleshoot common issues related to electrostatic paint application?

Some common troubleshooting steps for electrostatic paint application include:

- Check the spray gun and ensure it is clean, properly assembled, and free of any blockages or leaks.

- Verify the power supply to the electrostatic paint system and ensure the voltage and amperage are within the recommended ranges.

- Inspect the grounding system and make sure the workpiece and the spray gun are properly grounded to prevent static buildup.

- Examine the paint hoses and connections for any kinks or leaks that could affect the paint flow or cause pressure fluctuations.

- Monitor the paint level in the reservoir and refill it promptly to prevent air from entering the system and causing sputtering or inconsistent spraying.

4. How do you maintain the electrostatic paint system to ensure optimal performance?

To maintain optimal performance of the electrostatic paint system, I follow a regular maintenance schedule that includes:

- Cleaning the spray gun, hoses, and filters to remove paint residue and prevent blockages.

- Inspecting the power supply and electrical components for any signs of wear or damage.

- Checking the grounding system to ensure proper conductivity and prevent static buildup.

- Calibrating the paint pump and monitoring the pressure to maintain consistent paint flow.

- Storing the paint system in a clean and dry environment when not in use.

5. How do you ensure that the coated surfaces meet the required quality standards?

To ensure the coated surfaces meet the required quality standards, I adhere to the following practices:

- Thoroughly prepare the surfaces before painting to remove any contaminants or imperfections.

- Apply the electrostatic paint evenly and consistently, following the manufacturer’s guidelines and industry best practices.

- Inspect the coated surfaces regularly during the application process to identify any defects or inconsistencies.

- Perform quality checks after the paint has cured, including visual inspection, thickness measurement, and adhesion testing, to ensure compliance with specifications.

- Maintain accurate records of the painting process, including materials used, settings, and inspection results, to facilitate traceability and continuous improvement.

6. How do you handle and store electrostatic paint materials safely?

To handle and store electrostatic paint materials safely, I follow these precautions:

- Wear appropriate personal protective equipment (PPE), including gloves, eye protection, and a respirator, when handling paint materials.

- Store paint materials in a well-ventilated area away from heat sources and ignition hazards.

- Keep paint containers tightly sealed to prevent evaporation and contamination.

- Dispose of waste paint and solvents according to local regulations and industry best practices.

- Follow the manufacturer’s instructions and safety guidelines for handling and storing electrostatic paint materials.

7. How do you work effectively as part of a team in a production environment?

To work effectively as part of a team in a production environment, I focus on the following:

- Communicating clearly and regularly with team members to ensure smooth coordination and avoid misunderstandings.

- Collaborating with colleagues to solve problems, share knowledge, and support each other’s tasks.

- Adhering to established safety protocols and procedures to maintain a safe and productive work environment.

- Assisting others when needed and being willing to help out in different areas of the production process.

- Maintaining a positive and proactive attitude, even during challenging situations, to contribute to a cohesive and efficient team environment.

8. How do you stay up-to-date on the latest advancements in electrostatic paint technology?

To stay up-to-date on the latest advancements in electrostatic paint technology, I actively engage in the following activities:

- Attend industry conferences, workshops, and webinars to learn about emerging technologies and best practices.

- Read trade publications, technical articles, and manufacturer’s literature to stay informed about new developments.

- Connect with experts in the field, such as equipment manufacturers, paint suppliers, and industry professionals, to exchange knowledge and insights.

- Participate in discussion forums and online communities dedicated to electrostatic painting to stay abreast of industry trends and innovations.

- Seek opportunities to experiment with new techniques and technologies in a controlled environment to gain practical experience.

9. How do you ensure that the electrostatic paint system is operating efficiently and minimizes waste?

To ensure the electrostatic paint system is operating efficiently and minimizing waste, I implement the following measures:

- Optimizing the spray gun settings, including voltage, air pressure, and paint flow rate, to achieve the desired coating thickness and transfer efficiency.

- Maintaining proper grounding to prevent static buildup and ensure the paint particles are effectively attracted to the workpiece.

- Using high-quality paint materials that are compatible with the electrostatic system and minimize overspray and waste.

- Regularly cleaning and maintaining the spray gun, hoses, and filters to prevent blockages and ensure smooth paint flow.

- Properly disposing of waste paint and solvents according to environmental regulations to reduce the impact on the environment.

10. How do you handle situations where the electrostatic paint system is not performing optimally?

When the electrostatic paint system is not performing optimally, I take the following steps to troubleshoot and resolve the issue:

- Inspect the spray gun, hoses, and connections for any blockages or damage that could affect the paint flow or charging process.

- Check the power supply and ensure the voltage and amperage are within the recommended ranges for the electrostatic system.

- Verify the grounding system and make sure the workpiece and the spray gun are properly grounded to prevent static buildup.

- Adjust the spray gun settings, such as voltage and air pressure, to optimize the paint transfer efficiency and minimize waste.

- If necessary, consult with the equipment manufacturer or a qualified technician for further troubleshooting and support.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Electrostatic Paint Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Electrostatic Paint Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

An Electrostatic Paint Operator is responsible for operating and maintaining electrostatic paint equipment. The key responsibilities include:1. Preparing and Cleaning Equipment

Preparing electrostatic paint sprayers, mixing paint, and adjusting settings.

- Ensuring proper cleaning and maintenance of equipment to prevent contamination and ensure optimal performance.

- Monitoring paint levels and replenishing as needed.

2. Applying Electrostatic Paint

Applying electrostatic paint to surfaces using spray guns or other applicators.

- Controlling the spray pattern, thickness, and coverage to achieve the desired finish.

- Adjusting electrode settings to optimize paint transfer efficiency and minimize overspray.

3. Monitoring and Troubleshooting

Monitoring the painting process to ensure proper application and adherence to specifications.

- Identifying and troubleshooting any issues with equipment or paint application.

- Making necessary adjustments to ensure consistent and high-quality results.

4. Safety and Compliance

Adhering to all safety protocols and regulations related to electrostatic painting.

- Wearing appropriate personal protective equipment (PPE) and following safety procedures.

- Complying with environmental regulations and ensuring proper waste disposal.

Interview Tips

To ace an interview for an Electrostatic Paint Operator position, candidates should prepare thoroughly and consider the following tips:1. Research the Company and Position

Research the company’s background, products/services, and company culture.

- Demonstrate your understanding of the industry and company’s practices.

- Tailor your resume and cover letter to highlight relevant skills and experience.

2. Highlight Technical Skills

Emphasize your knowledge of electrostatic painting principles, equipment, and safety procedures.

- Provide examples of your experience in preparing, applying, and troubleshooting electrostatic paint equipment.

- Discuss your understanding of different types of paints and coatings, as well as their applications.

3. Show Attention to Detail

Electrostatic painting requires precision and attention to detail. Highlight your meticulous nature and commitment to quality.

- Describe your experience in following technical specifications and quality standards.

- Emphasize your ability to perform precise and consistent painting tasks.

4. Communication and Team Skills

Electrostatic Paint Operators often work in teams and interact with other departments. Demonstrate your communication and interpersonal skills.

- Provide examples of your ability to follow instructions, collaborate with others, and resolve issues effectively.

- Highlight your willingness to learn from others and contribute to a positive work environment.

5. Prepare for Common Questions

Anticipate and prepare answers to common interview questions related to electrostatic painting.

- Practice describing your experience with different electrostatic sprayers and nozzles.

- Prepare for questions about your troubleshooting and problem-solving skills.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Electrostatic Paint Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.