Feeling lost in a sea of interview questions? Landed that dream interview for Element Burner but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Element Burner interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

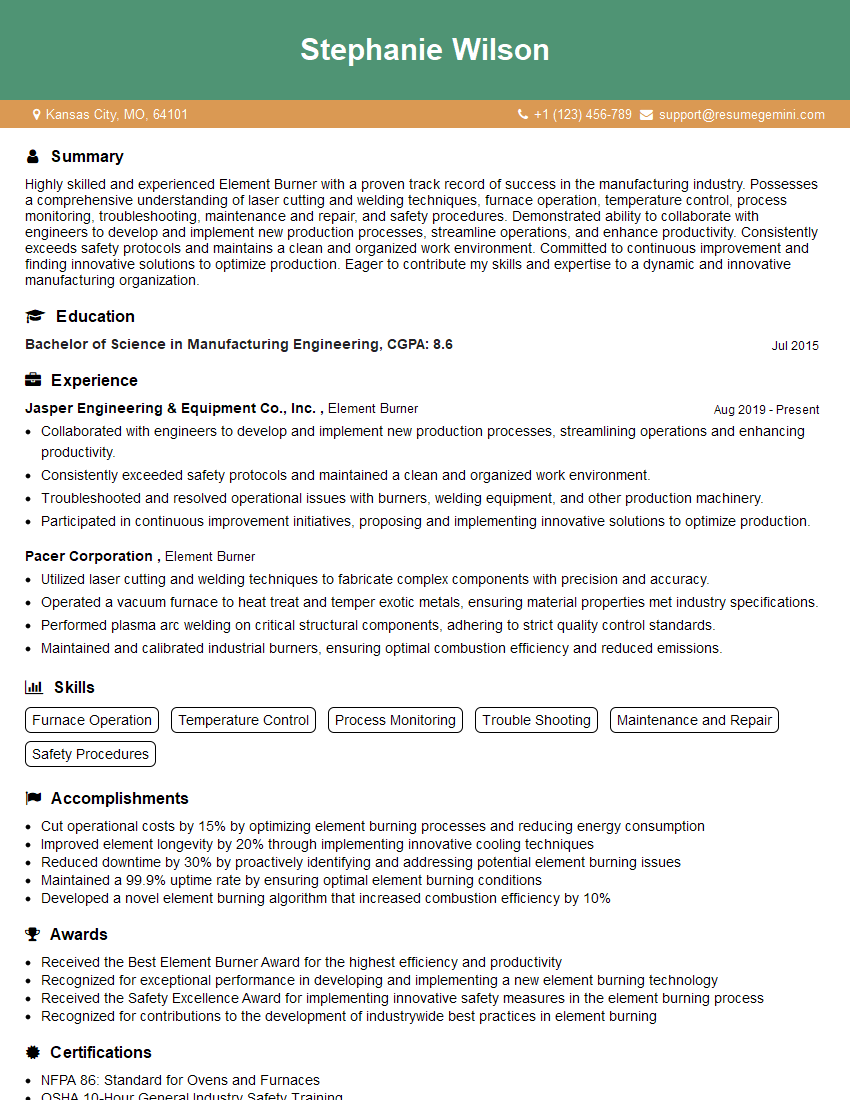

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Element Burner

1. What is the purpose of using an Element Burner?

An Element Burner is a device used to heat and combust various elements and compounds. It is commonly employed in analytical chemistry and materials science to conduct elemental analysis, atomic absorption spectroscopy, and other analytical techniques.

- It generates high-temperature flames to excite and dissociate atoms, leading to the emission of characteristic wavelengths of light.

- The emitted light is measured and analyzed to determine the elemental composition and concentration in the sample.

2. What are the different types of Element Burners and their applications?

Flame Element Burners

- Use a combustible gas (e.g., hydrogen, acetylene) and an oxidant (e.g., air, oxygen) to produce a flame.

- Suitable for a wide range of elements and applications, including atomic absorption and flame emission spectroscopy.

Graphite Furnace Element Burners

- Heat a small graphite tube or platform to high temperatures using an electric current.

- Used for analyzing trace elements in solid or liquid samples, often in conjunction with atomic absorption spectroscopy.

Inductively Coupled Plasma (ICP) Element Burners

- Generate a high-temperature plasma using an argon gas and an induction coil.

- Capable of analyzing a wide range of elements with high precision and sensitivity, used in ICP-OES and ICP-MS techniques.

3. How do you optimize the performance of an Element Burner?

Optimizing Element Burner performance involves controlling various parameters:

- Fuel and Oxidant Flow Rates: Adjust the flow rates to achieve the desired flame temperature and stability.

- Sample Introduction: Ensure proper sample introduction techniques to minimize contamination and enhance accuracy.

- Burner Alignment: Align the burner correctly with the optical path to maximize light intensity and reduce background noise.

- Maintenance: Regularly clean and maintain the burner to prevent clogging and ensure optimal performance.

4. What are the potential hazards associated with using an Element Burner?

Element Burners involve high temperatures and flammable gases, posing potential hazards:

- Burns: Contact with the high-temperature flame or hot surfaces can cause severe burns.

- Explosions: Improper handling of flammable gases can lead to explosions.

- Toxic Fumes: Combustion of certain elements or compounds can release toxic fumes.

- Electrical Hazards: Some Element Burners use electrical components that may pose electrical shock hazards.

5. What safety precautions are necessary when operating an Element Burner?

To ensure safety when operating an Element Burner, follow these precautions:

- Protective Gear: Wear appropriate personal protective equipment, including gloves, safety glasses, and a lab coat.

- Proper Ventilation: Ensure adequate ventilation to remove any toxic fumes or gases.

- Training and Supervision: Receive proper training on the operation and safety protocols of the Element Burner.

- Follow Operating Procedures: Adhere strictly to the manufacturer’s operating instructions and safety guidelines.

6. How do you troubleshoot common Element Burner issues?

Common issues with Element Burners and their troubleshooting steps include:

- Erratic Flame: Check fuel and oxidant flow rates, clean the burner head, or adjust the burner alignment.

- Low Signal Intensity: Optimize sample introduction, check burner alignment, or clean the optical path.

- Clogging: Regularly clean the burner head and sample introduction system to prevent buildup and ensure proper flow.

- Electrical Malfunctions: Contact a qualified electrician to diagnose and repair any electrical issues.

7. What are the latest advancements in Element Burner technology?

Recent advancements in Element Burner technology include:

- Microfluidics Integration: Miniaturized burners for high-throughput and portable analysis.

- Novel Flame Designs: Optimized flame profiles for enhanced sensitivity and reduced interferences.

- Advanced Control Systems: Automated burner control and optimization using machine learning algorithms.

- Environmentally Friendly Burners: Low-emission burners that minimize environmental impact.

8. How do you stay updated on the latest developments in Element Burner technology?

To stay informed about the latest developments in Element Burner technology:

- Attend Conferences and Workshops: Participate in industry events and workshops to learn about new techniques and advancements.

- Read Scientific Journals: Stay up-to-date with the latest research publications and technical articles.

- Network with Experts: Connect with researchers, manufacturers, and other professionals in the field to exchange knowledge and insights.

- Explore Online Resources: Utilize online databases, forums, and websites dedicated to Element Burner technology.

9. What are your career aspirations in the field of Element Burner technology?

My career aspirations in the field of Element Burner technology include:

- Research and Development: Contribute to the development of innovative burner designs and analytical techniques.

- Applications Development: Explore new applications of Element Burner technology in various scientific and industrial fields.

- Technical Consulting: Provide expert guidance and support to clients in optimizing their Element Burner systems.

- Education and Training: Share knowledge and train others on the principles and applications of Element Burner technology.

10. Do you have any questions for me about the Element Burner position or our company?

I am eager to learn more about the specific responsibilities and expectations of this Element Burner position. I am also interested in understanding the company’s vision and commitment to advancing Element Burner technology.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Element Burner.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Element Burner‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

An Element Burner is responsible for handling and operating a variety of burners and furnaces used in industrial and manufacturing settings.

1. Burner and Furnace Operation

Tasks include:

- Setting up and calibrating burners and furnaces according to specifications.

- Igniting, monitoring, and adjusting burners to achieve optimal combustion efficiency.

- Maintaining and troubleshooting burner and furnace systems to ensure smooth operation.

2. Material Handling and Preparation

Tasks include:

- Loading and unloading materials into and out of burners and furnaces.

- Preparing materials for combustion, such as crushing, screening, and mixing.

3. Quality Control

Tasks include:

- Monitoring and testing combustion processes to ensure product quality meets specifications.

- Conducting routine inspections and maintenance to identify and address potential quality issues.

4. Safety and Environmental Compliance

Tasks include:

- Adhering to all safety regulations and procedures related to burner and furnace operation.

- Preventing and controlling emissions and waste to comply with environmental standards.

Interview Tips

To ace an interview for an Element Burner position, consider the following tips:

1. Research the Company and Position

Learn about the company’s industry, products, and culture. Familiarize yourself with the specific requirements of the Element Burner role, as described in the job description.

2. Highlight Relevant Skills and Experience

Emphasize your skills in burner and furnace operation, material handling, quality control, and safety. Provide specific examples from your previous work experience that demonstrate your proficiency in these areas.

3. Prepare for Technical Questions

Expect questions about combustion principles, burner types, furnace design, and troubleshooting techniques. Review basic concepts and prepare to discuss your understanding of these topics.

4. Showcase Safety Awareness

Stress your commitment to safety and adherence to regulations. Highlight your knowledge of proper safety procedures, personal protective equipment, and emergency protocols.

5. Be Enthusiastic and Professional

Convey your passion for the field and your eagerness to contribute to the company’s success. Maintain a professional demeanor, dress appropriately, and arrive on time for your interview.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Element Burner interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!