Feeling lost in a sea of interview questions? Landed that dream interview for Emulsion Coater but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Emulsion Coater interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

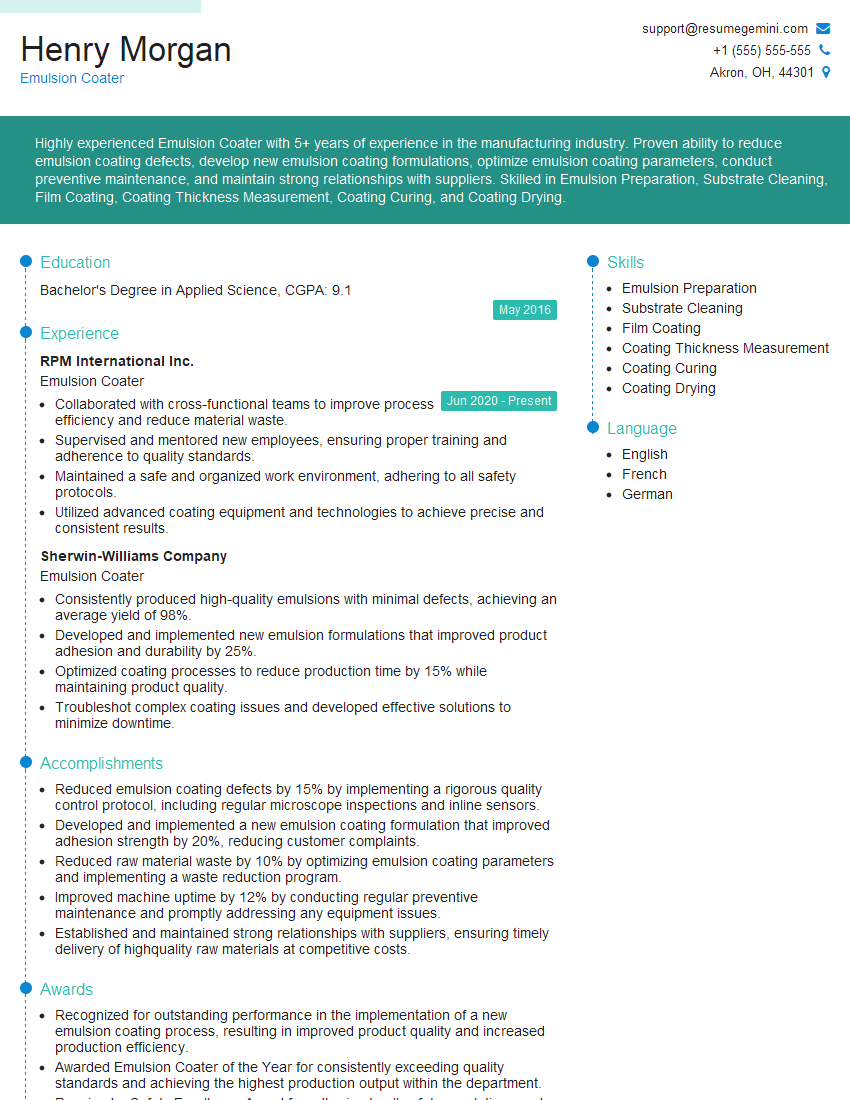

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Emulsion Coater

1. What are the key responsibilities of an Emulsion Coater?

As an Emulsion Coater, my main responsibilities include:

- Preparing and mixing emulsion coatings according to specified formulas.

- Applying coatings to various materials, such as paper, textiles, and plastics, using automated or manual equipment.

- Monitoring and adjusting coating thickness and quality to meet production standards.

- Maintaining and cleaning coating equipment to ensure optimal performance.

- Troubleshooting and resolving coating defects or issues.

2. Describe the different types of emulsion coatings and their applications.

Water-based emulsion coatings

- Used in a wide range of applications, including interior and exterior paints, adhesives, and paper coatings.

- Advantages: Easy to apply, fast drying, and environmentally friendly.

Solvent-based emulsion coatings

- Provide excellent durability and resistance to chemicals and solvents.

- Used in industrial applications, such as metal coatings, automotive finishes, and marine paints.

UV-curable emulsion coatings

- Cured using ultraviolet light, resulting in instant drying and high cross-linking density.

- Used in specialized applications, such as electronics, printing, and wood finishes.

3. What factors affect the quality of emulsion coatings?

The quality of emulsion coatings is influenced by several factors, including:

- Emulsion formulation: The composition and ratio of ingredients, such as resins, pigments, and additives, impact the coating’s properties.

- Coating thickness: The thickness of the applied coating affects its durability, appearance, and performance.

- Application method: Proper application techniques, such as spray painting or roller coating, ensure uniform coverage and optimal results.

- Drying conditions: Temperature, humidity, and ventilation during the drying process influence the coating’s curing and adhesion.

4. How do you troubleshoot common coating defects and issues?

To troubleshoot coating defects and issues, I follow these steps:

- Identify the defect or issue based on its appearance, such as bubbles, cracks, or unevenness.

- Check the emulsion formulation, coating thickness, and application method to determine potential causes.

- Conduct tests or experiments to isolate the root cause of the issue.

- Adjust the emulsion formulation, coating parameters, or application techniques to resolve the defect.

- Monitor the results and make further adjustments as needed to optimize coating quality.

5. What safety precautions should be taken when handling and applying emulsion coatings?

When handling and applying emulsion coatings, I adhere to the following safety precautions:

- Wear appropriate personal protective equipment, such as gloves, masks, and eye protection.

- Ensure proper ventilation in the workspace to avoid inhalation of fumes or vapors.

- Handle and store chemicals, such as solvents and additives, according to safety data sheets.

- Dispose of waste materials and empty containers in an environmentally responsible manner.

- Follow established company policies and procedures for safety and hazard communication.

6. Describe the role of quality control in emulsion coating production.

Quality control plays a crucial role in emulsion coating production by ensuring:

- Conformance to specifications: Testing and inspections verify that coatings meet required standards and customer expectations.

- Consistency and uniformity: Quality control measures help maintain consistent coating properties and prevent variations.

- Defect detection and prevention: Regular monitoring and inspections identify potential defects and allow for corrective actions.

- Process optimization: Data analysis and feedback from quality control contribute to continuous improvement and process efficiency.

7. How do you stay up-to-date with the latest advancements in emulsion coating technology?

To stay up-to-date with the latest advancements in emulsion coating technology, I engage in the following activities:

- Attend industry conferences and workshops to learn about new materials, formulations, and techniques.

- Read technical journals and publications to stay informed about research and development in the field.

- Network with industry professionals and experts to exchange knowledge and best practices.

- Participate in training programs and certifications to enhance my skills and stay abreast of industry standards.

8. Describe a challenging project you worked on as an Emulsion Coater and how you overcame the challenges.

In a previous role, I encountered a challenge with a new emulsion coating formula that resulted in poor adhesion to the substrate. I conducted extensive testing and analysis to identify the root cause and isolate the problem.

By adjusting the formulation’s composition and modifying the application parameters, I was able to optimize the coating’s adhesion properties. The modified coating met the required specifications and improved the overall product quality.

9. How do you prioritize tasks and manage your time effectively when working on multiple projects?

To prioritize tasks and manage my time effectively, I follow these strategies:

- Use a task management tool or planner to keep track of deadlines and project details.

- Identify the most critical tasks and focus on completing them first.

- Break down large projects into smaller, manageable chunks to avoid feeling overwhelmed.

- Delegate tasks to others when possible to free up time for more important responsibilities.

- Take regular breaks and practice self-care to maintain productivity and focus.

10. Why are you interested in this Emulsion Coater position at our company?

I am eager to join your company as an Emulsion Coater because I am impressed by your commitment to innovation and quality in the coatings industry. I believe that my skills and experience would be a valuable asset to your team.

I am particularly interested in your company’s focus on sustainability and environmental responsibility. I am passionate about developing and implementing sustainable coating solutions that contribute to a greener future.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Emulsion Coater.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Emulsion Coater‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Emulsion Coaters play a crucial role in the manufacturing process by applying an emulsion coating to various materials. Their key job responsibilities include:

1. Preparing the emulsion

Candidates should be well-versed in preparing emulsion coatings according to specified formulas and guidelines, ensuring the right consistency, viscosity, and other parameters.

- Measuring and mixing raw materials

- Adjusting properties such as viscosity and pH

2. Operating emulsion coating machines

Candidates must demonstrate proficiency in operating emulsion coating machines, including setting up, calibrating, and maintaining equipment to achieve optimal coating results.

- Loading and unloading materials

- Monitoring coating parameters and making adjustments

3. Ensuring coating quality

Candidates should possess the ability to inspect and evaluate coated materials to ensure they meet quality standards, including thickness, adhesion, and uniformity.

- Conducting tests and measurements

- Identifying and correcting defects

4. Maintaining a clean and safe work environment

Candidates must adhere to safety protocols and maintain a clean and organized work area, including proper handling and disposal of chemicals.

- Following safety procedures

- Cleaning and maintaining equipment

Interview Tips

To enhance your chances of success in an Emulsion Coater interview, consider the following preparation tips:

1. Research the company and position

Familiarize yourself with the company’s industry, products, and values. Study the job description thoroughly to understand the specific requirements and expectations of the role.

- Visit the company website

- Review industry news and articles

2. Practice answering common interview questions

Prepare for typical interview questions related to your skills, experience, and qualifications. Anticipate questions about your knowledge of emulsion coating processes, quality control procedures, and safety protocols.

- Prepare a brief introduction highlighting your relevant skills

- Develop examples to demonstrate your experience in key areas

3. Showcase your technical knowledge

Emulsion Coaters should be technically proficient in coating processes and equipment. Emphasize your understanding of emulsion chemistry, coating techniques, and machine operation.

- Discuss your experience with different types of emulsion coatings

- Highlight your ability to troubleshoot and resolve technical issues

4. Highlight your attention to detail

Candidates must demonstrate their meticulous approach to quality control. Provide examples of your ability to inspect coated materials, identify defects, and implement corrective actions.

- Emphasize your commitment to accuracy and precision

- Share examples of how you have improved coating processes

5. Convey your commitment to safety

Emulsion Coaters must prioritize safety in their work. Showcase your understanding of safety procedures, proper handling of chemicals, and maintaining a clean and organized work environment.

- Discuss your experience in following safety protocols

- Highlight your awareness of industry safety regulations

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Emulsion Coater interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.