Are you gearing up for a career in Enamel Dipper? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Enamel Dipper and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

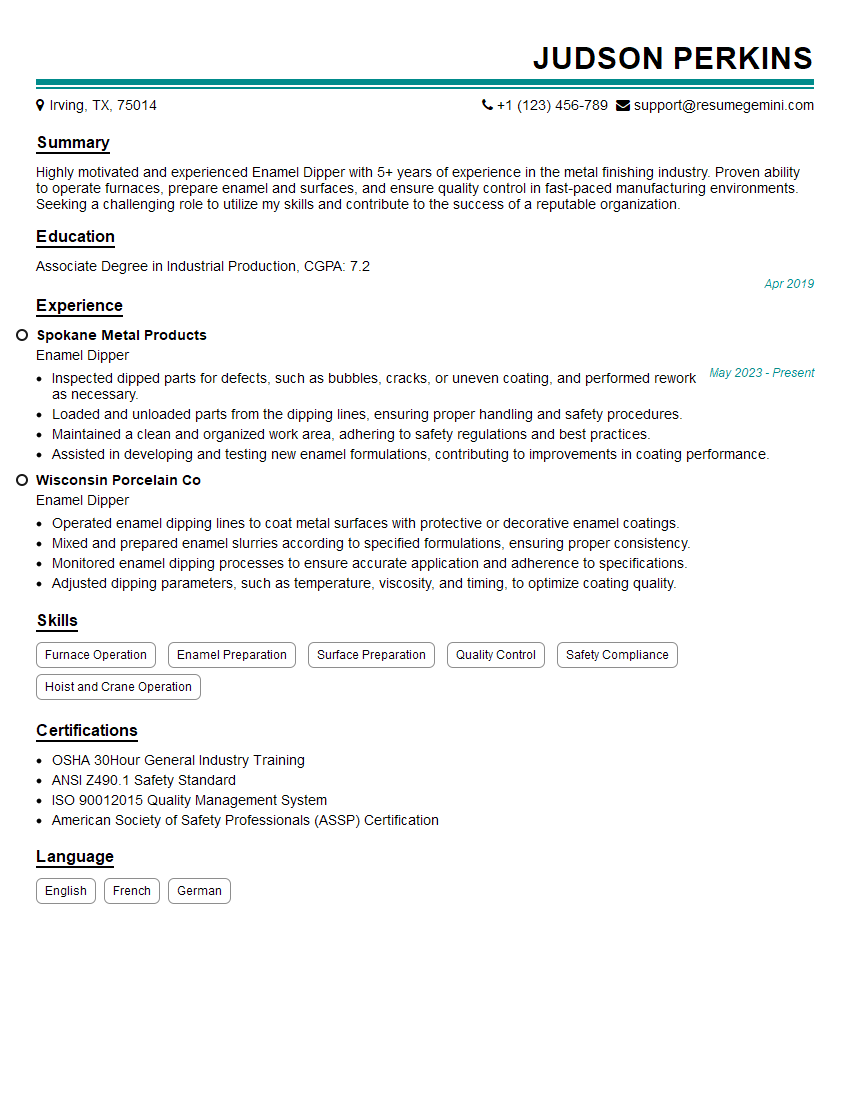

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Enamel Dipper

1. How do you ensure that the enamel coating is applied evenly and consistently to the entire surface of the workpiece?

To ensure even and consistent enamel coating application, I follow a meticulous process that involves:

- Thorough Surface Preparation: I meticulously clean and prepare the workpiece surface to remove any contaminants or unevenness that could affect adhesion.

- Precise Enamel Preparation: I carefully mix and prepare the enamel using the recommended ratios to achieve the desired consistency and viscosity.

- Controlled Application: I use specialized spray equipment or dipping techniques to apply the enamel evenly and consistently, ensuring uniform coverage across all areas.

- Multi-Layer Approach: To build up a durable and protective enamel coating, I apply multiple layers, allowing each layer to dry and cure properly between applications.

2. How do you handle different types of metal surfaces, such as iron, steel, and aluminum?

Handling different metal surfaces requires specific techniques and considerations:

Iron and Steel

- Surface Cleaning: I employ mechanical or chemical methods to remove rust, scale, or other impurities.

- Enamel Selection: I select enamel formulations specifically designed for ferrous metals to ensure proper adhesion and durability.

Aluminum

- Anodization: I perform anodization to create a protective oxide layer on the aluminum surface before enameling, enhancing adhesion.

- Enamel Compatibility: I use enamel formulations compatible with aluminum and its oxide layer to prevent delamination.

3. How do you troubleshoot common enamel defects, such as chipping, cracking, or blistering?

To effectively troubleshoot enamel defects, I follow a systematic approach:

- Defect Identification: I carefully examine the defect to determine its type, severity, and potential cause.

- Cause Analysis: I analyze factors such as surface preparation, enamel preparation, application technique, and curing conditions to identify the root cause.

- Corrective Actions: Based on the identified cause, I implement appropriate corrective actions, such as adjusting surface preparation methods, modifying enamel formulations, or refining application techniques.

- Re-evaluation: I re-evaluate the results to ensure the defect has been resolved and the enamel coating meets the desired quality standards.

4. How do you stay up to date with the latest advancements in enamel dipping techniques?

To remain updated with the latest advancements in enamel dipping techniques, I engage in continuous learning:

- Industry Publications: I subscribe to trade magazines and journals to stay informed about new technologies, best practices, and industry trends.

- Conferences and Workshops: I attend industry events and workshops to learn from experts, network with peers, and gain hands-on experience with emerging techniques.

- Online Resources: I utilize online platforms, forums, and webinars to access up-to-date information and engage with the enamel dipping community.

5. How do you ensure the safety of the enamel dipping process for yourself and others?

Ensuring the safety of the enamel dipping process is paramount:

- Proper Ventilation: I work in well-ventilated areas to prevent exposure to fumes and particles.

- Protective Gear: I wear appropriate personal protective equipment (PPE), including gloves, respirators, and eye protection.

- Safe Handling of Chemicals: I follow established procedures for handling, storing, and disposing of enamel materials and solvents.

- Emergency Preparedness: I am trained in emergency response protocols and have access to safety equipment in case of accidents.

6. How do you determine the optimal firing temperature and time for different enamel formulations?

To determine the optimal firing temperature and time for different enamel formulations, I consider several factors:

- Enamel Composition: I study the technical data sheets provided by enamel manufacturers to understand the recommended firing parameters.

- Workpiece Material: I take into account the thermal properties of the workpiece material, such as its expansion coefficient, to avoid damage during firing.

- Kiln Calibration: I regularly calibrate my kiln to ensure accurate temperature readings and maintain consistent firing conditions.

- Test Firing: I conduct test firings with small samples to determine the optimal firing parameters empirically, ensuring the enamel melts and fuses properly without overfiring or underfiring.

7. How do you ensure the quality of the final enamel finish, including color accuracy and gloss level?

To ensure the quality of the final enamel finish:

- Color Matching: I use color charts and spectrophotometers to accurately match the desired color.

- Gloss Control: I adjust the enamel formulation and firing parameters to achieve the desired gloss level, from matte to high-gloss.

- Surface Inspection: I meticulously inspect the finished enamel surface for defects, such as pinholes, bubbles, or unevenness, and rectify any issues.

8. How do you handle the disposal of enamel waste and wastewater?

Responsible disposal of enamel waste and wastewater is essential:

- Waste Segregation: I separate enamel waste, such as sludge and spent solvents, from general waste.

- Waste Treatment: I employ appropriate waste treatment methods, such as chemical neutralization or solidification, to render waste non-hazardous.

- Wastewater Treatment: I comply with environmental regulations and utilize wastewater treatment facilities to remove contaminants before discharge.

9. How do you assess the wear resistance and durability of the enamel coating?

To assess the wear resistance and durability of the enamel coating, I perform various tests:

- Abrasion Testing: I use equipment such as the Taber Abraser to simulate wear and tear, measuring the resistance to scratching and abrasion.

- Impact Testing: I conduct impact tests to evaluate the coating’s ability to withstand mechanical shocks.

- Chemical Resistance Testing: I expose the enamel coating to different chemicals and solvents to determine its resistance to corrosion and staining.

- Field Testing: I perform real-world testing in actual use conditions to assess the long-term performance and durability.

10. How do you maintain and calibrate the equipment used in the enamel dipping process?

Proper maintenance and calibration of equipment are crucial for consistent and high-quality enamel dipping:

- Regular Maintenance: I adhere to maintenance schedules, including cleaning, lubrication, and replacement of worn parts.

- Calibration: I regularly calibrate equipment, such as spray guns, kilns, and measuring devices, to ensure accuracy and precision.

- Equipment Troubleshooting: I am proficient in troubleshooting and resolving common equipment issues, minimizing downtime.

- Quality Control: I implement quality control measures throughout the enamel dipping process to ensure equipment is functioning properly and producing consistent results.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Enamel Dipper.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Enamel Dipper‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Enamel Dippers are responsible for applying a protective coating of enamel to metal objects, such as cookware, appliances, and jewelry. Their duties involve preparing the objects, applying the enamel, and ensuring the quality of the finished product.

1. Preparing the Objects

Before applying enamel, Enamel Dippers must prepare the objects by cleaning and removing any impurities or oxidation. This may involve using solvents, abrasives, or other cleaning agents.

2. Applying the Enamel

Once the objects are prepared, Enamel Dippers apply the enamel using a variety of techniques, such as dipping, spraying, or brushing. They must ensure that the enamel is applied evenly and consistently, and that the desired thickness is achieved.

3. Firing the Objects

After the enamel has been applied, the objects are fired in a kiln to melt and harden the enamel. Enamel Dippers must monitor the firing process carefully to ensure that the enamel achieves the desired properties, such as hardness, durability, and color.

4. Inspecting the Finished Product

Once the objects have been fired, Enamel Dippers inspect them to ensure that they meet the required standards of quality. They may check for defects, such as bubbles, cracks, or discoloration, and make any necessary adjustments or repairs.

Interview Tips

Preparing for an interview for an Enamel Dipper position can help you present your skills and experience effectively and increase your chances of success. Here are some tips to help you ace the interview:

1. Research the Company and Position

Familiarize yourself with the company’s products, services, and culture. Research the specific role of an Enamel Dipper within the organization. This will help you understand the company’s needs and tailor your answers accordingly.

2. Practice Your Answers

Anticipate common interview questions and prepare your responses. Practice answering questions related to your skills, experience, and why you are interested in the position. Feedback from friends, family, or a career counselor can be valuable.

3. Emphasize Relevant Skills and Experience

Highlight your skills in enamel application, kiln firing, and quality control. Quantify your experience whenever possible to demonstrate your impact. For example, you could mention the number of objects you enamelled per day or the percentage of products that met quality standards.

4. Be Enthusiastic and Show Passion

Enamelling is a specialized field, so showing enthusiasm and passion for the craft can make a positive impression. Discuss your interest in enamel work and how it aligns with your career goals.

5. Ask Thoughtful Questions

Asking thoughtful questions at the end of the interview shows your interest and engagement. Prepare questions about the company, the position, or the industry. This is an opportunity to clarify any remaining doubts and demonstrate your curiosity.

6. Professionalism and Follow Up

Dress professionally and arrive on time for the interview. Be courteous and respectful to everyone you meet. After the interview, send a thank-you note to the interviewer, restating your interest in the position and reiterating your key strengths.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Enamel Dipper role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.