Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Engineer, Foundry Process position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

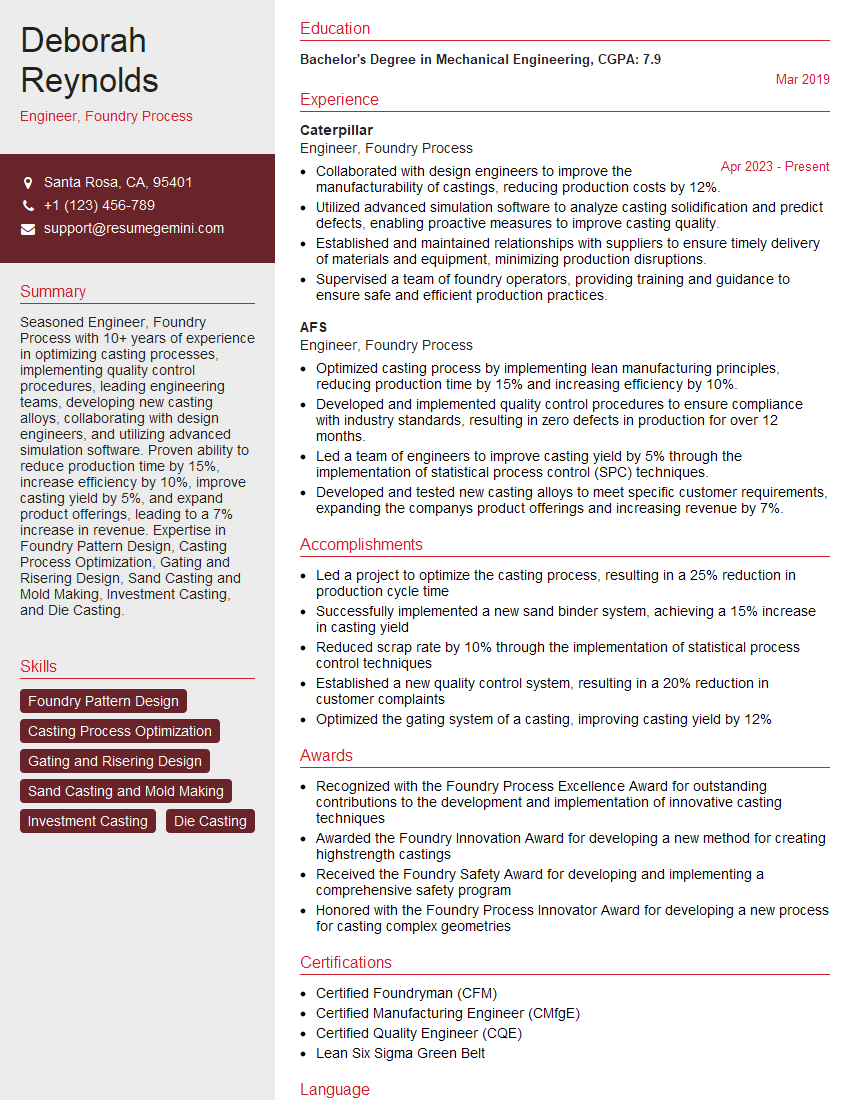

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Engineer, Foundry Process

1. What are the different types of casting processes used in foundries?

- Sand casting

- Investment casting

- Die casting

- Permanent mold casting

- Centrifugal casting

2. What are the key factors that affect the quality of castings?

Metallurgical factors

- Composition of the molten metal

- Grain size of the metal

- Inclusion content of the metal

Molding factors

- Type of molding material

- Mold design

- Molding process

Casting factors

- Pouring temperature

- Cooling rate

- Solidification conditions

3. What are the different types of defects that can occur in castings?

- Shrinkage defects

- Gas defects

- Inclusion defects

- Solidification defects

- Molding defects

- Casting defects

4. What are the preventive measures that can be taken to minimize defects in castings?

- Proper design of castings

- Use of high-quality materials

- Proper molding techniques

- Proper casting techniques

- Proper heat treatment of castings

5. What are the different types of testing methods used to evaluate the quality of castings?

- Visual inspection

- Dimensional inspection

- Metallurgical testing

- Mechanical testing

- Non-destructive testing

6. What is the role of the Foundry Engineer in the manufacturing process?

- To design and develop casting processes

- To ensure the quality of castings

- To improve the efficiency of the foundry

- To reduce the cost of castings

7. What are the key challenges faced by the foundry industry?

- The increasing cost of raw materials

- The increasing competition from other manufacturing processes

- The need for to improve the quality and efficiency of castings

- The need to meet environmental regulations

8. What are the latest trends in the foundry industry?

- The use of advanced casting technologies

- The use of computer-aided design and manufacturing (CAD/CAM) systems

- The use of robots and automation in the foundry

- The development of new materials for castings

- The focus on sustainability and environmental protection

9. What are your strengths and weaknesses as a Foundry Engineer?

- Expertise in the design and development of casting processes

- Strong knowledge of the metallurgy of castings

- Experience in the use of CAD/CAM systems

- Ability to work in a team environment

Strengths

- Limited experience in the use of robots and automation in the foundry

- Need to improve my knowledge of environmental regulations

- Need to improve my ability to communicate with customers

Weaknesses

10. Why are you interested in working for our company?

- I am impressed by your company’s commitment to quality and innovation.

- I believe that my skills and experience would be a valuable asset to your team.

- I am confident that I can make a significant contribution to your company’s success.

11. How do you stay up-to-date on the latest trends in the foundry industry?

- I read trade publications and attend industry conferences.

- I am a member of professional organizations, such as the American Foundry Society.

- I network with other foundry engineers and professionals.

12. What are your career goals for the next 5 years?

- To become a leading expert in the design and development of casting processes.

- To help my company become the leading supplier of castings in the world.

- To make a significant contribution to the foundry industry.

13. What are you most proud of in your career?

- I am most proud of the work I did on the development of a new casting process that significantly reduced the cost of castings.

- I am also proud of the work I did on the implementation of a new CAD/CAM system that improved the efficiency of the foundry.

14. What is your salary expectation?

- My salary expectation is in the range of [insert salary range].

- I am confident that my skills and experience are worth this amount.

- I am open to negotiation, but I am not willing to accept a salary that is below my expectations.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Engineer, Foundry Process.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Engineer, Foundry Process‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

An Engineer, Foundry Process, plays a pivotal role in overseeing and optimizing foundry processes to ensure the efficient and high-quality production of metal castings.

1. Process and Quality Management

Oversee all aspects of foundry processes, from raw material selection to casting, heat treatment, and finishing.

- Establish and maintain quality standards for all foundry operations.

- Monitor and analyze production data to identify areas for improvement.

2. Process Development and Improvement

Conduct research and implement new technologies and processes to enhance efficiency and quality.

- Collaborate with cross-functional teams to optimize casting design and manufacturing processes.

- Develop and implement process control plans to ensure consistent production.

3. Material Management and Testing

Manage raw materials and ensure their proper storage and handling.

- Perform material testing and analysis to evaluate material properties.

- Develop and maintain inventory systems for raw materials and finished products.

4. Equipment Maintenance and Troubleshooting

Maintain and repair foundry equipment to ensure optimal performance.

- Troubleshoot production issues and implement corrective actions.

- Collaborate with maintenance personnel to ensure equipment is in good working order.

Interview Tips

To ace an interview for an Engineer, Foundry Process position, it’s essential to prepare thoroughly and demonstrate your knowledge, skills, and enthusiasm for the role.

1. Research the Company and Position

Thoroughly research the company’s history, products, and values to gain an understanding of their operations and culture.

- Identify the specific responsibilities and requirements of the Engineer, Foundry Process position.

- Consider how your skills and experience align with the company’s needs.

2. Highlight Your Technical Expertise

Provide concrete examples of your proficiency in foundry processes, materials, and testing techniques.

- Quantify your accomplishments and demonstrate your ability to drive improvements.

- Discuss your experience with specific casting technologies and equipment.

3. Emphasize Your Problem-Solving Skills

Highlight your ability to analyze data, identify problems, and develop innovative solutions.

- Describe specific instances where you successfully solved complex casting or production challenges.

- Explain your approach to troubleshooting and root cause analysis.

4. Showcase Your Communication and Teamwork Abilities

Emphasize your ability to work effectively with colleagues, supervisors, and clients.

- Provide examples of your experience in collaborating on cross-functional projects.

- Highlight your ability to communicate technical information clearly and persuasively.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Engineer, Foundry Process interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!