Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Failure Analysis Technician (FA Technician) position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

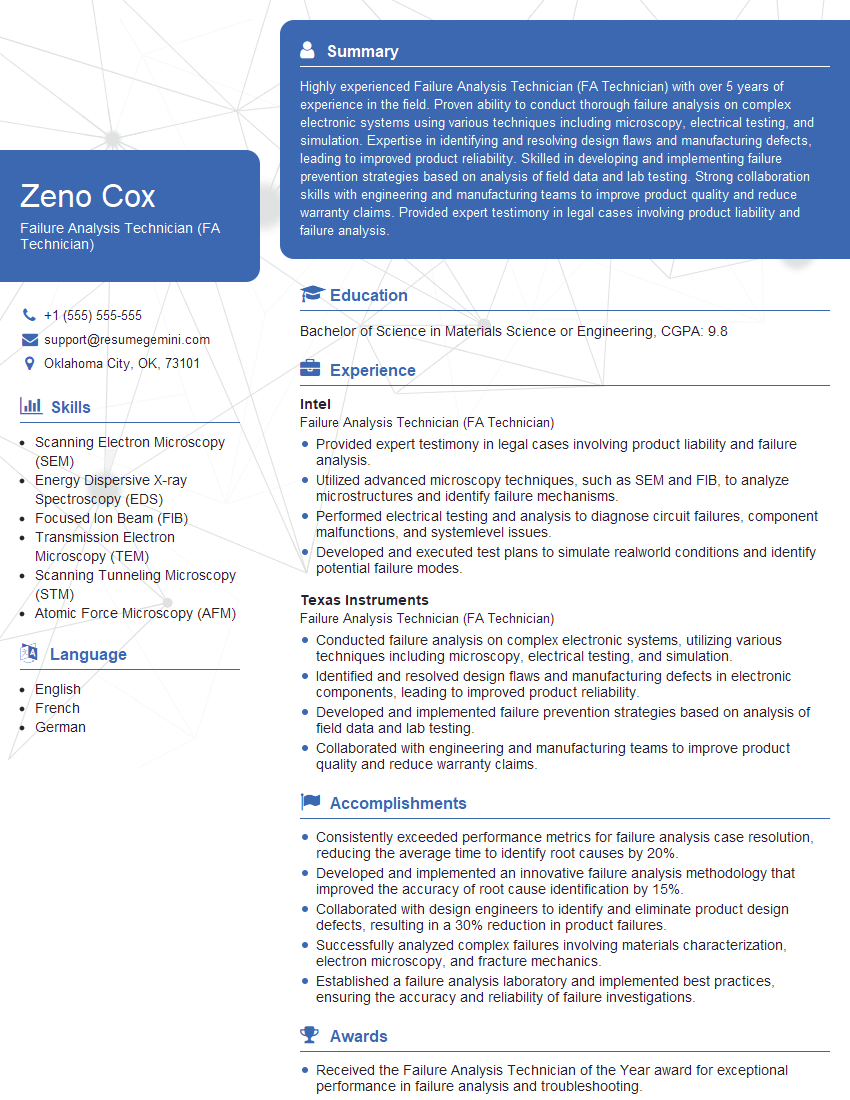

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Failure Analysis Technician (FA Technician)

1. What are the different types of failure analysis techniques, and when would you use each one?

There are a variety of failure analysis techniques, each with its own strengths and weaknesses. The most common techniques include:

- Visual inspection: This is the most basic technique, and it can be used to identify obvious defects such as cracks, corrosion, and deformation.

- Microscopy: This technique can be used to examine the microstructure of materials, which can help to identify defects such as grain boundaries, inclusions, and voids.

- Chemical analysis: This technique can be used to identify the elemental composition of materials, which can help to determine the cause of failure.

- Mechanical testing: This technique can be used to measure the mechanical properties of materials, such as strength, ductility, and toughness.

- Electrical testing: This technique can be used to measure the electrical properties of materials, such as conductivity, resistance, and capacitance.

The choice of which technique to use depends on the specific failure being investigated, as well as the available resources and expertise.

2. What is the difference between a failure analysis and a root cause analysis?

Failure analysis

- Focuses on identifying the immediate cause of a failure.

- Typically involves a detailed examination of the failed component.

- May also include testing and analysis to determine the root cause of the failure.

Root cause analysis

- Focuses on identifying the underlying causes of a failure.

- Typically involves a systematic investigation of the system or process that led to the failure.

- May also include interviews with personnel and review of documentation.

Failure analysis is typically the first step in a root cause analysis. Once the immediate cause of a failure has been identified, a root cause analysis can be conducted to determine the underlying causes of the failure and to prevent similar failures from occurring in the future.

3. What are the most common types of failures that you have encountered in your experience?

The most common types of failures that I have encountered in my experience include:

- Mechanical failures: These failures are caused by mechanical stress, such as fatigue, wear, and corrosion.

- Electrical failures: These failures are caused by electrical stress, such as overvoltage, overcurrent, and short circuits.

- Chemical failures: These failures are caused by chemical reactions, such as oxidation, corrosion, and contamination.

- Environmental failures: These failures are caused by environmental factors, such as temperature, humidity, and vibration.

- Human error: These failures are caused by mistakes made by humans, such as design errors, manufacturing errors, and maintenance errors.

4. What are the most important factors to consider when performing a failure analysis?

The most important factors to consider when performing a failure analysis include:

- The type of failure

- The severity of the failure

- The potential for the failure to cause injury or damage

- The cost of the failure

- The availability of resources

- The time constraints

5. What are the different ways to prevent failures?

There are a number of different ways to prevent failures, including:

- Design for reliability: This involves designing products and systems to be as reliable as possible.

- Testing: This involves testing products and systems to identify and eliminate defects.

- Quality control: This involves implementing processes and procedures to ensure that products and systems are manufactured and maintained to a high standard.

- Maintenance: This involves regularly inspecting and servicing products and systems to prevent failures from occurring.

- Training: This involves training personnel on how to properly operate and maintain products and systems.

6. What are the challenges of working as a failure analysis technician?

The challenges of working as a failure analysis technician include:

- Dealing with complex and challenging failures

- Working under pressure to meet deadlines

- Working with a variety of people, including engineers, technicians, and customers

- Keeping up with the latest technology

- Managing a heavy workload

7. What are the rewards of working as a failure analysis technician?

The rewards of working as a failure analysis technician include:

- Solving challenging problems

- Making a difference in the world by preventing failures

- Working with a variety of people

- Learning about new technology

- Having a challenging and rewarding career

8. What is your favorite part of working as a failure analysis technician?

My favorite part of working as a failure analysis technician is solving challenging problems. I enjoy the challenge of figuring out why a product or system has failed, and then developing a solution to prevent the failure from happening again.

9. What is your biggest accomplishment as a failure analysis technician?

My biggest accomplishment as a failure analysis technician was solving a problem that had been plaguing a major manufacturer for years. The manufacturer was experiencing a high rate of failures in a critical component of their product. I was able to identify the root cause of the failures and develop a solution that eliminated the problem.

10. What are your career goals?

My career goal is to become a lead failure analysis technician. I would like to continue to learn and grow in my field, and I am eager to take on more responsibility. I am confident that I have the skills and experience to be successful in this role.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Failure Analysis Technician (FA Technician).

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Failure Analysis Technician (FA Technician)‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Failure Analysis Technician (FA Technician) plays a crucial role in identifying and analyzing product or component failures within the manufacturing process. The key job responsibilities of an FA Technician encompass:

1. Failure Analysis and Investigation

Investigating and analyzing product or component failures to determine root causes

- Conducting visual and microscopic inspections, electrical measurements, and material testing

- Interpreting test results to identify potential causes of failure

2. Developing Corrective Actions

Recommending and implementing corrective actions to prevent future failures

- Analyzing failure data and proposing design or process modifications

- Collaborating with engineers and production teams to implement corrective measures

3. Quality Control

Ensuring the quality and reliability of products by identifying and addressing potential issues

- Performing statistical analysis to identify trends and patterns in product failures

- Implementing quality control measures to minimize the risk of future failures

4. Technical Support

Providing technical support to other departments and customers regarding product or component failures

- Explaining failure analysis results to customers and stakeholders

- Developing and conducting training programs to enhance failure analysis skills

Interview Preparation Tips

To ace an interview for an FA Technician position, it is crucial to prepare thoroughly. Here are some key tips:

1. Research the Company and the Role

Gain a comprehensive understanding of the company, its products or services, and the specific responsibilities of the FA Technician role.

2. Highlight Your Skills and Experience

Emphasize your technical expertise in failure analysis, particularly in the areas of microscopy, electrical testing, and materials science.

3. Quantify Your Accomplishments

Provide concrete examples of your successful failure analysis investigations and the resulting impact on product quality or customer satisfaction.

4. Demonstrate Your Problem-Solving Abilities

Highlight your ability to analyze complex problems, identify root causes, and develop effective solutions.

5. Show Your Passion for Continuous Learning

Indicate your commitment to expanding your knowledge and skills in the field of failure analysis.

6. Practice Answering Common Interview Questions

Prepare for commonly asked interview questions such as:

- Tell us about your experience in failure analysis.

- Describe a time when you identified and resolved a complex product failure.

- How do you approach a failure analysis investigation?

- What are the challenges and rewards of being an FA Technician?

7. Show Enthusiasm and Curiosity

Convey your enthusiasm for the role and your eagerness to contribute to the organization’s success.

Next Step:

Now that you’re armed with the knowledge of Failure Analysis Technician (FA Technician) interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Failure Analysis Technician (FA Technician) positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini