Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Faucets Assembler position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

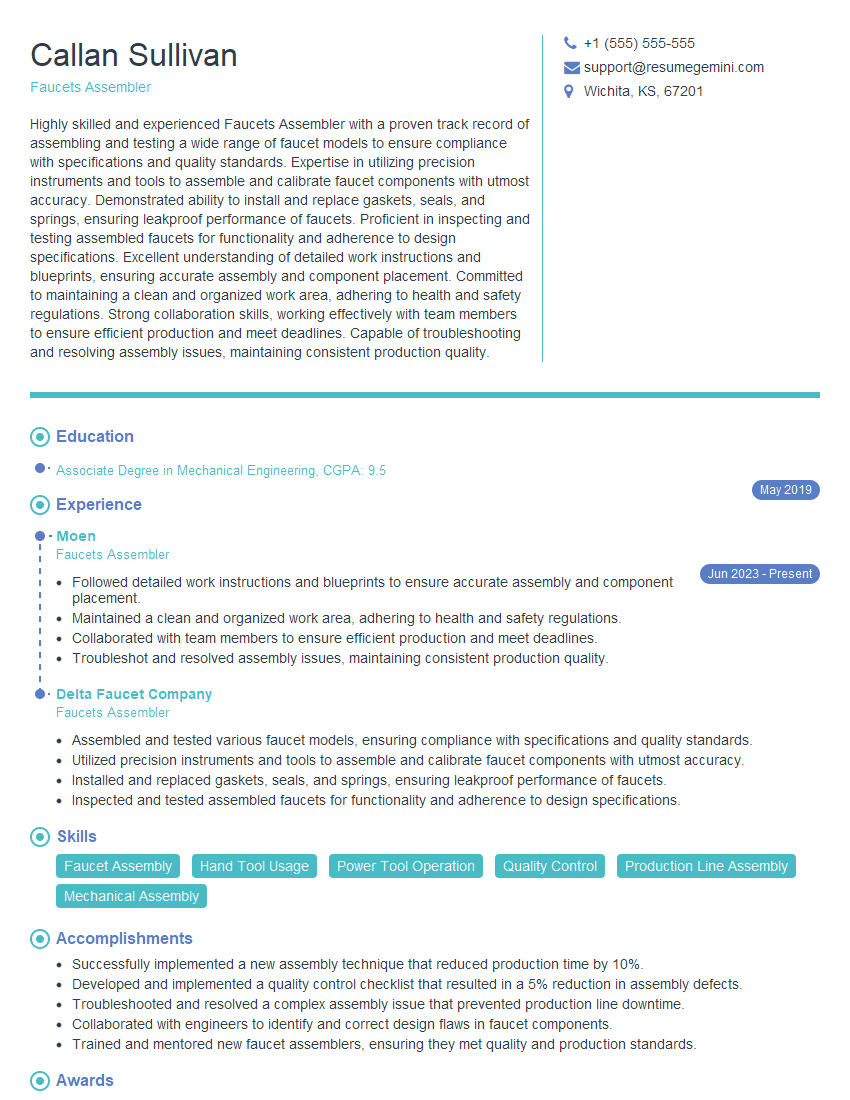

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Faucets Assembler

1. What are the key steps involved in assembling a faucet?

The key steps involved in assembling a faucet are:

- Inspecting the components to ensure they are complete and in good condition.

- Assembling the handle and stem.

- Installing the cartridge or valve.

- Connecting the water lines.

- Installing the faucet body.

- Attaching the spout.

- Testing the faucet for leaks.

2. What tools and equipment are required to assemble a faucet?

Hand tools

- Adjustable wrench

- Allen wrench

- Channel-lock pliers

- Crescent wrench

- Phillips screwdriver

- Flathead screwdriver

Special tools

- Faucet puller

- Faucet seat wrench

- O-ring pick

- Compression nut driver

3. What safety precautions should be taken when assembling a faucet?

The following safety precautions should be taken when assembling a faucet:

- Wear eye protection.

- Wear gloves.

- Use sharp tools carefully.

- Do not overtighten the nuts and bolts.

- Test the faucet for leaks before using it.

4. What are some common problems that can occur during faucet assembly?

Some common problems that can occur during faucet assembly include:

- Leaks

- Loose handles

- Sticking valves

- Damaged components

- Incorrect installation

5. How do you troubleshoot and repair a leaking faucet?

To troubleshoot and repair a leaking faucet, you can follow these steps:

- Identify the source of the leak.

- Tighten the loose nuts or bolts.

- Replace the worn or damaged O-rings or washers.

- Clean the faucet aerator.

- Replace the cartridge or valve.

6. What is the difference between a compression faucet and a cartridge faucet?

Compression faucets use a washer to seal the water flow, while cartridge faucets use a cartridge to control the water flow. Compression faucets are generally less expensive and easier to repair than cartridge faucets, but cartridge faucets are more durable and provide a smoother water flow.

7. What are the different types of faucet finishes?

The different types of faucet finishes include:

- Chrome

- Brushed nickel

- Oil-rubbed bronze

- Polished brass

- Matte black

8. What are the advantages of using a faucet with a water-saving feature?

The advantages of using a faucet with a water-saving feature include:

- Reduced water usage

- Lower water bills

- Increased water conservation

- Reduced environmental impact

9. What is the proper way to dispose of a used faucet?

The proper way to dispose of a used faucet is to recycle it. Faucets are made of metal, which can be recycled and used to make new products.

10. How do you stay up-to-date on the latest faucet trends and technologies?

I stay up-to-date on the latest faucet trends and technologies by reading industry publications, attending trade shows, and networking with other professionals in the field.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Faucets Assembler.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Faucets Assembler‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Faucets Assembler is responsible for assembling and testing faucets, ensuring they meet quality standards. They work in a manufacturing environment, utilizing various tools and equipment to complete their tasks. To excel in this role, candidates should possess a strong attention to detail, manual dexterity, and knowledge of assembly processes. Key responsibilities include:

1. Assemble Faucets

Assemble faucets according to blueprints and specifications, using hand tools and power tools.

- Follow assembly instructions precisely to ensure proper functioning.

- Inspect components for defects before assembly.

2. Test Faucets

Conduct functional tests on assembled faucets to verify their performance and identify any defects.

- Operate faucets to check for leaks, proper flow rate, and smooth operation.

- Document test results and report any issues to supervisors.

3. Maintain Assembly Area

Maintain a clean and organized work area, ensuring proper storage of tools and materials.

- Inspect tools and equipment regularly to ensure they are in good working condition.

- Keep work area free of debris and hazardous materials.

4. Follow Safety Procedures

Adhere to all safety regulations and guidelines to prevent accidents and injuries.

- Wear appropriate safety gear, such as gloves, goggles, and earplugs.

- Operate machinery and equipment safely, following established protocols.

Interview Tips

To prepare effectively for a Faucets Assembler interview, consider the following tips:

1. Research the Company and Position

Familiarize yourself with the company’s products, history, and mission statement. Research the specific position you are applying for to understand the responsibilities and requirements.

2. Highlight Relevant Skills and Experience

Emphasize your manual dexterity, attention to detail, and experience in assembling mechanical components. Showcase any previous experience in the manufacturing industry, particularly in faucet assembly.

3. Practice Common Interview Questions

Prepare answers to common interview questions, such as “Tell me about yourself,” “Why are you interested in this role,” and “What are your strengths and weaknesses?”

4. Prepare Questions for the Interviewer

Asking thoughtful questions at the end of the interview demonstrates your interest and engagement. Prepare questions related to the company’s culture, growth opportunities, or specific aspects of the position.

Next Step:

Now that you’re armed with the knowledge of Faucets Assembler interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Faucets Assembler positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini