Are you gearing up for a career in Felt Strip Finisher? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Felt Strip Finisher and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

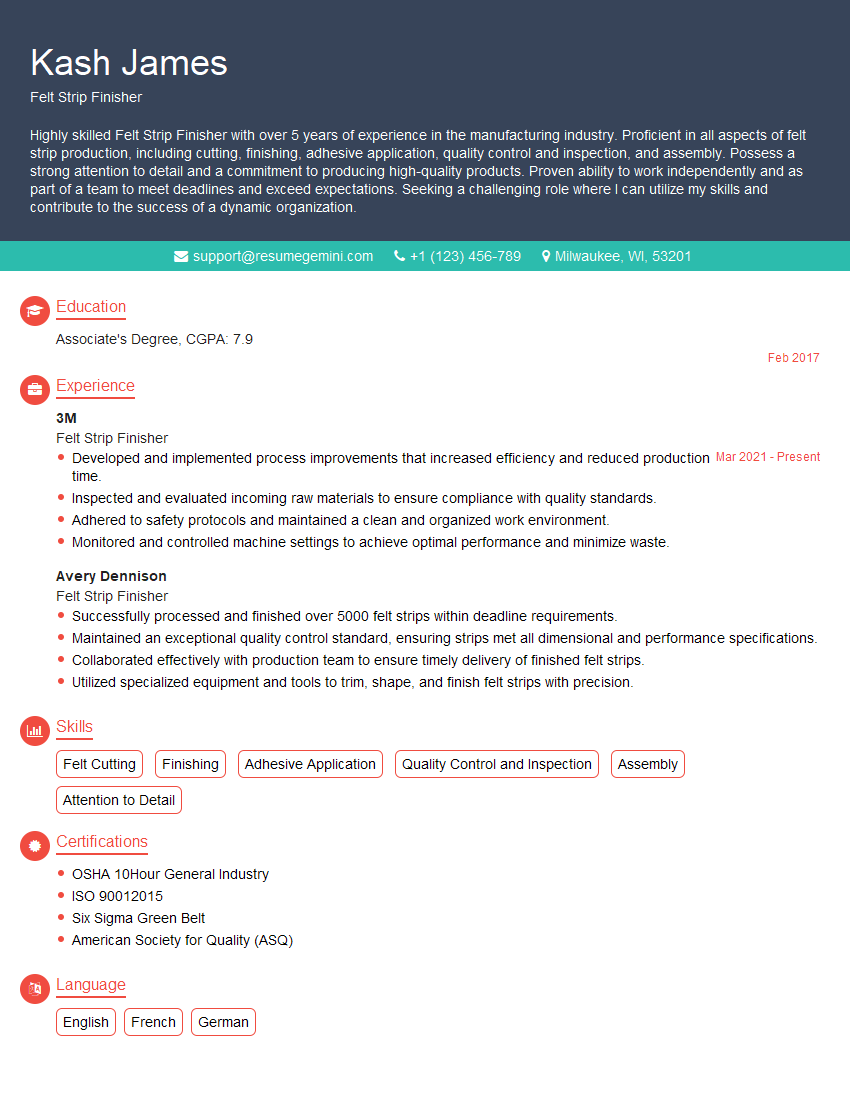

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Felt Strip Finisher

1. What are the key responsibilities of a Felt Strip Finisher?

As a Felt Strip Finisher, I am responsible for the precision cutting, shaping, and finishing of felt strips used in various industrial and consumer products. I ensure that the strips meet specifications for thickness, width, and length, and that they are free of defects.

2. Describe the process of cutting and shaping felt strips.

Cutting

- Select the appropriate felt material and thickness.

- Measure and mark the desired length and width on the felt.

- Use a sharp cutting tool (e.g., razor blade or band knife) to cut the felt precisely.

Shaping

- Determine the desired shape of the felt strip.

- Use cutting tools or dies to shape the felt to the required dimensions.

- Ensure that the shaped felt strip meets the specified tolerances.

3. How do you control the thickness and width of the felt strips?

To control the thickness and width of the felt strips, I use precision measuring tools such as calipers and micrometers. I ensure that the incoming felt material meets the required specifications. During the cutting process, I carefully measure and mark the desired dimensions on the felt. I use sharp cutting tools and specialized jigs or templates to achieve accurate cuts.

4. What techniques do you use to remove burrs and imperfections from the felt strips?

- Sanding or abrasive blasting to smoothen the edges and remove any burrs.

- Trimming and hand finishing to remove excess material and refine the shape.

- Using solvents or chemicals to clean and remove any surface imperfections.

- Inspecting each strip under magnification to ensure a high-quality finish.

5. Describe the different types of felt materials and their applications.

- Wool felt: Natural fibers, provides excellent insulation and sound absorption.

- Synthetic felt: Made from man-made fibers, offers durability and resistance to chemicals.

- Blended felt: Combination of wool and synthetic fibers, provides a balance of properties.

- Needled felt: Non-woven, interlocking fibers, high strength and abrasion resistance.

- Punched felt: Holes punched into the felt, allowing for breathability and flexibility.

6. How do you ensure that the finished felt strips meet customer specifications?

- Thoroughly review the customer’s specifications and requirements.

- Inspect each felt strip at various stages of production using precision measuring tools.

- Maintain accurate records of quality checks and measurements.

- Make adjustments to the cutting and finishing processes as needed to meet the specified tolerances.

7. What safety precautions do you take when working with felt strips?

- Wear appropriate personal protective equipment (PPE), including gloves, safety glasses, and a dust mask.

- Handle sharp cutting tools with care and follow proper safety protocols.

- Ensure that the work area is well-ventilated to minimize exposure to dust and fumes.

- Store and handle felt materials safely to prevent fire or accidents.

8. What software or equipment do you use to assist in your work?

- Computer-aided design (CAD) software for creating cutting templates.

- Laser or waterjet cutting machines for precise cutting.

- Measuring tools such as calipers, micrometers, and height gauges.

- Quality control equipment for inspection and testing.

9. How do you stay updated on industry trends and best practices in felt strip finishing?

- Attend industry conferences and workshops.

- Read trade publications and technical journals.

- Seek feedback from colleagues and supervisors.

- Explore online resources and participate in industry forums.

10. Describe a challenging situation you faced as a Felt Strip Finisher and how you resolved it.

In one instance, I encountered a batch of felt material that was thicker than the specified tolerance. This posed a challenge as it could affect the final dimensions of the felt strips. To resolve this issue, I worked closely with the supplier to identify the root cause of the discrepancy. We adjusted the cutting parameters and used a precision thickness gauge to ensure that the strips met the required specifications. By taking proactive measures and collaborating with the supplier, I was able to deliver high-quality felt strips while maintaining production efficiency.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Felt Strip Finisher.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Felt Strip Finisher‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Felt Strip Finishers are responsible for the final finishing of felt strips, ensuring they meet the required specifications and quality standards.

1. Felt Cutting and Slitting

Operate cutting machines to cut felt into strips of various widths and lengths.

- Measure and mark the felt to ensure accurate cutting.

- Set and adjust machine settings based on the required strip dimensions.

2. Edge Finishing

Finish the edges of the felt strips to remove any rough or uneven edges.

- Use sanding or grinding machines to smooth and shape the edges.

- Inspect the edges for any defects or imperfections.

3. Quality Inspection

Inspect the finished felt strips to ensure they meet the specified quality standards.

- Check the dimensions, thickness, and shape of the strips.

- Identify and correct any defects or imperfections.

4. Finishing and Packaging

Prepare the finished felt strips for packaging and shipment.

- Roll or fold the strips according to the customer’s specifications.

- Label and package the strips for shipping.

Interview Tips

Preparing for an interview is crucial for success. Here are some tips to help you ace your Felt Strip Finisher interview:

1. Research the Company and Position

Before the interview, thoroughly research the company and the specific position you’re applying for. This shows the interviewer that you’re genuinely interested in the opportunity and that you’ve taken the time to understand the company’s culture and goals.

- Visit the company website to learn about its mission, values, and industry standing.

- Read industry publications and news articles to stay updated on the latest trends and developments in the field.

2. Practice Answering Common Interview Questions

Familiarize yourself with common interview questions and prepare your answers in advance. This will help you feel more confident and prepared during the interview.

- Questions about your experience and qualifications.

- Questions about your motivation and interest in the position.

- Questions about your strengths and weaknesses.

3. Showcase Your Skills and Experience

Highlight your relevant skills and experience that align with the job requirements. Provide specific examples of your accomplishments and how they have benefited previous employers.

- Quantify your achievements whenever possible using specific metrics or data.

- Use the STAR method (Situation, Task, Action, Result) when answering behavioral questions.

4. Be Punctual and Professional

Punctuality and professionalism are essential for a successful interview. Arrive on time for your interview and dress appropriately. Maintain eye contact with the interviewer, speak clearly and confidently, and be respectful of their time.

- Allow ample time for traveling and parking to avoid any delays.

- Dress in a suit or professional attire that is clean and pressed.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Felt Strip Finisher interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!