Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Felting Machine Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

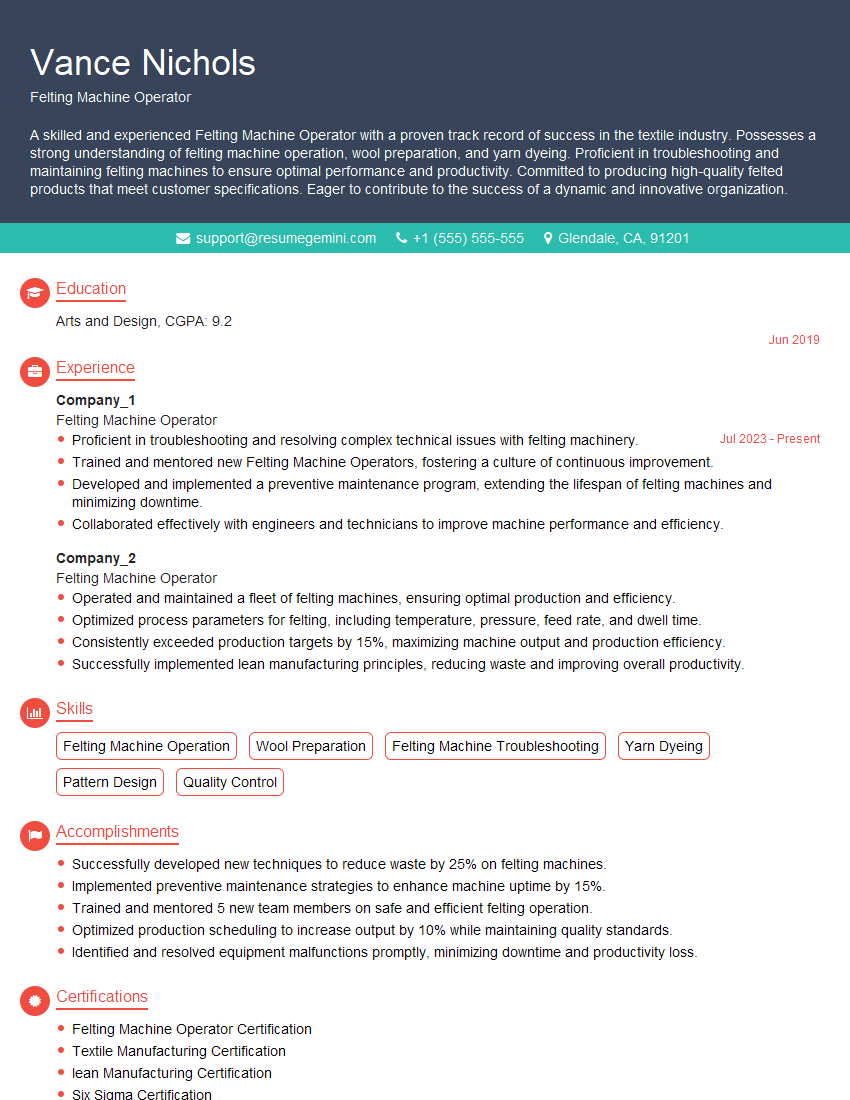

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Felting Machine Operator

1. Describe the process of operating a Felting Machine?

The operation of a felting machine involves several key steps:

- Material Loading: Load the raw material, typically natural or synthetic fibers, onto the machine’s conveyor belt.

- Pre-Wetting: Immerse the fibers in a water solution to prepare them for felting.

- Felting: Subject the wetted fibers to mechanical agitation within a perforated drum or chamber, causing the fibers to entangle and bond together.

- Drying: Extract excess moisture from the felted material using heat or air circulation.

- Finishing: Inspect the finished felt for quality and perform any necessary trimming or shaping.

2. What are the different types of Felting Machines?

There are several types of felting machines used in the industry, each with its own characteristics:

Wet Felting Machines:

- Needle Punching Machines: Use barbed needles to punch fibers together, creating a dense and durable felt.

- Hydraulic Needle Looms: Employ water jets to guide needles through fibers, producing a softer and more uniform felt.

Dry Felting Machines:

- Roller Carding Machines: Use rotating rollers with fine teeth to separate and align fibers before felting.

- Air Laying Machines: Distribute fibers evenly onto a conveyor belt using air jets, creating a uniform felt base.

3. What factors affect the quality of felted products?

The quality of felted products is influenced by several factors:

- Fiber Type and Properties: The type, length, and crimp of the fibers used affect the felt’s softness, strength, and texture.

- Felting Process Parameters: The temperature, agitation intensity, and duration of the felting process determine the felt’s density and consistency.

- Additives: Chemicals or resins added during felting can enhance the felt’s properties, such as fire resistance or water repellency.

- Finishing Techniques: Trimming, shaping, and other finishing processes impact the felt’s final appearance and performance.

4. How do you troubleshoot common problems with Felting Machines?

Common problems and troubleshooting steps for felting machines include:

- Uneven Felting: Check for blockages or tears in the conveyor belt or felting chamber.

- Poor Fiber Entanglement: Adjust the agitation intensity or duration to promote better fiber bonding.

- Excess Moisture: Optimize the drying process to remove excess moisture and prevent mold or mildew.

- Mechanical Issues: Inspect and maintain machine components regularly to prevent breakdowns.

5. What safety precautions should be observed when operating a Felting Machine?

Safety precautions for operating a felting machine include:

- Protective Clothing: Wear gloves, safety glasses, and appropriate clothing to protect from moving parts and flying fibers.

- Guarding: Ensure that all machine guards and covers are in place and functioning properly.

- Lockout/Tagout: Follow established procedures for lockout/tagout before performing maintenance or repairs.

- Emergency Stop: Be familiar with the location and operation of the emergency stop button.

6. Describe the different types of fibers used in felting?

Various types of fibers are used in felting, each with unique properties:

- Natural Fibers: Wool, mohair, alpaca, silk, and cotton are commonly used for their softness, insulation, and moisture absorption.

- Synthetic Fibers: Polyester, nylon, and acrylic are popular choices for their durability, resistance to shrinkage, and ease of care.

- Blends: Combining natural and synthetic fibers creates felt with tailored properties, such as durability and comfort.

7. How do you ensure the consistency and quality of felted products?

Ensuring consistency and quality in felted products involves:

- Standardized Process: Establish and follow standardized operating procedures for all steps of the felting process.

- Raw Material Control: Maintain consistent fiber quality by sourcing from trusted suppliers and performing incoming inspections.

- Machine Calibration: Calibrate and maintain felting machines regularly to ensure accuracy and precision.

- Quality Control: Implement quality control measures, including regular testing and inspection, to identify and address any deviations.

8. What are the applications of felted products?

Felted products have a wide range of applications, including:

- Textiles: Clothing, blankets, insulation, and soundproofing materials.

- Industrial: Filtration systems, gaskets, and vibration dampeners.

- Automotive: Interior components, such as headliners and carpets.

- Medical: Wound dressings, orthopedic casts, and surgical products.

9. How do you handle machine breakdowns or malfunctions?

In the event of a machine breakdown or malfunction:

- Safety First: Immediately shut down the machine and ensure the safety of yourself and others.

- Troubleshooting: Attempt to identify the cause of the issue based on your knowledge and training.

- Maintenance: If capable, perform basic maintenance tasks, such as replacing fuses or tightening bolts.

- Reporting: Notify the appropriate supervisor or maintenance personnel and provide detailed information about the issue.

10. How do you stay updated with the latest advancements in felting technology?

To stay updated on the latest advancements in felting technology:

- Industry Events: Attend trade shows and conferences to learn about new products and innovations.

- Technical Publications: Subscribe to industry magazines and journals to read articles on the latest developments.

- Online Resources: Utilize online forums, websites, and social media groups to connect with other professionals and stay informed about industry trends.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Felting Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Felting Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

As a Felting Machine Operator, you will play a vital role in the production process by operating and maintaining felting machines. Your key responsibilities include:

1. Machine Operation

You will be responsible for the safe and efficient operation of felting machines, ensuring that they are set up and adjusted according to production requirements.

- Loading and unloading raw materials, such as wool, fiber, and dyes

- Monitoring the felting process to ensure that the desired thickness, density, and texture are achieved

- Adjusting machine settings to maintain optimal operating conditions

2. Machine Maintenance

You will also be responsible for the regular maintenance and upkeep of felting machines, ensuring that they operate at peak performance.

- Performing routine inspections and cleaning

- Identifying and troubleshooting any issues or malfunctions

- Conducting minor repairs and adjustments

- Reporting any major maintenance or repair needs to supervisors

3. Quality Control

You will be responsible for ensuring the quality of the felted products produced by the machines.

- Inspecting felted products for defects or inconsistencies

- Maintaining records of production output and quality

- Implementing quality control measures to prevent or reduce defects

4. Safety and Compliance

You will be responsible for maintaining a safe and compliant work environment.

- Following all established safety protocols and procedures

- Wearing appropriate personal protective equipment (PPE)

- Maintaining a clean and organized work area

- Complying with all applicable regulations and standards

Interview Tips

To help you ace your interview for a Felting Machine Operator position, here are some valuable tips:

1. Research the Company and the Role

Familiarize yourself with the company’s history, products, and values. Research the specific role you are applying for, paying attention to the key responsibilities outlined in the job description. This will demonstrate your interest and enthusiasm.

- Visit the company’s website and social media pages

- Look up industry news and articles related to felting

- Prepare questions to ask the interviewer about the company and the role

2. Highlight Your Skills and Experience

Tailor your resume and cover letter to emphasize the skills and experience that are most relevant to the Felting Machine Operator role. Use specific examples to demonstrate your technical abilities, such as machine operation, maintenance, and quality control.

- Quantify your accomplishments whenever possible

- Use action verbs to describe your responsibilities

- Highlight your ability to work independently and as part of a team

3. Practice Your Answers

Take time to prepare thoughtful answers to common interview questions. Practice your responses out loud to build confidence and ensure that your answers are clear and concise.

- Consider potential questions about your experience, skills, and knowledge

- Develop concise and well-structured answers

- Practice answering questions in front of a mirror or with a friend

4. Dress Professionally and Arrive on Time

First impressions matter, so dress professionally for your interview. Arrive on time to show that you respect the interviewer’s time. Being punctual and well-dressed demonstrates your professionalism and attention to detail.

- Choose clothing that is appropriate for an industrial setting

- Make sure your clothing is clean and pressed

- Arrive at the interview location with plenty of time to spare

5. Be Positive and Enthusiastic

Throughout the interview, maintain a positive and enthusiastic attitude. Show the interviewer that you are genuinely interested in the role and the company. Your enthusiasm will make a lasting impression and communicate your passion for the industry.

- Smile, make eye contact, and speak confidently

- Ask insightful questions to show your engagement

- Thank the interviewer for their time and consideration

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Felting Machine Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.