Feeling lost in a sea of interview questions? Landed that dream interview for Fiber Drier Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Fiber Drier Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

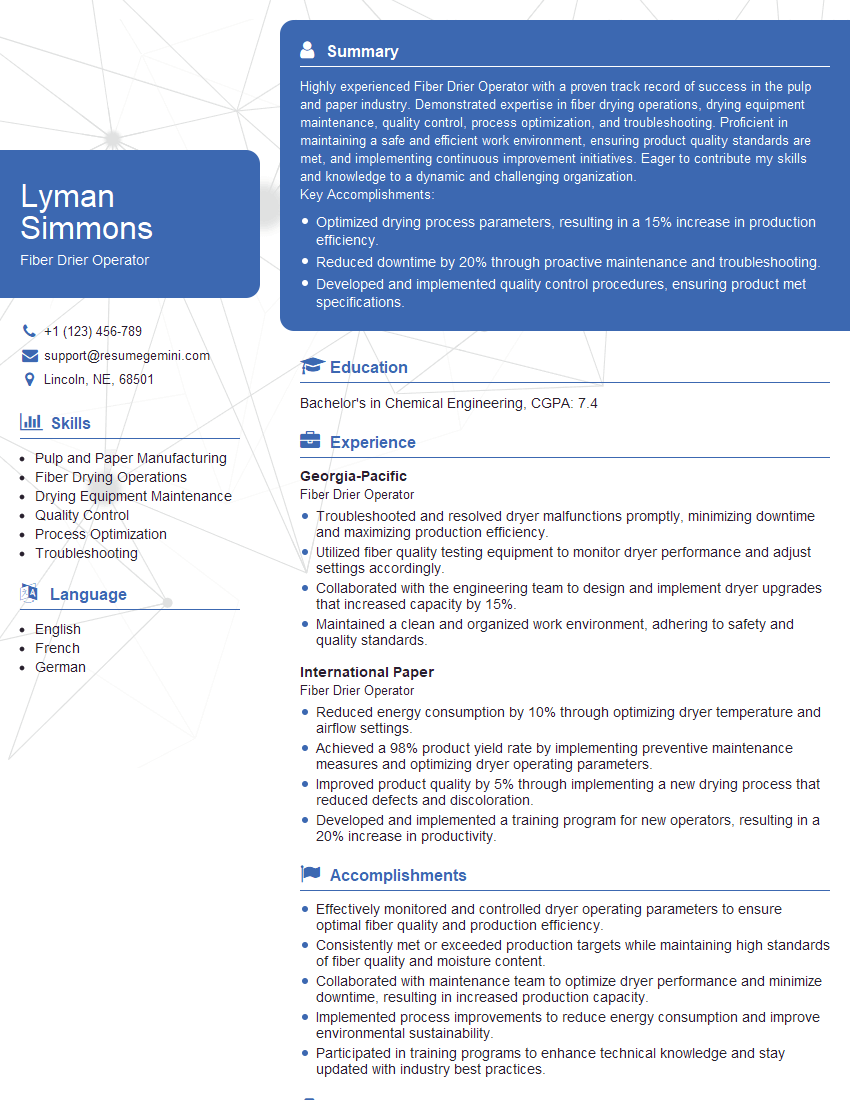

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Fiber Drier Operator

1. Explain the different types of fiber driers and their uses?

- Rotary dryers: Used for drying large volumes of fiber, such as wood chips or sawdust. They consist of a rotating cylinder that tumbles the fiber while hot air is blown through it.

- Flash dryers: Used for drying fine powders or granules. They consist of a chamber where the fiber is suspended in a stream of hot air and quickly dried.

- Band dryers: Used for drying continuous sheets of fiber, such as paper or fabric. They consist of a series of heated bands that carry the fiber through a drying zone.

2. What are the key parameters that need to be monitored and controlled during the drying process?

Temperature:

- The temperature of the drying air must be carefully controlled to ensure that the fiber is dried properly without damaging it.

- Too high a temperature can cause the fiber to scorch or burn, while too low a temperature will not dry the fiber sufficiently.

Humidity:

- The humidity of the drying air must also be controlled to prevent the fiber from becoming too dry or too wet.

- Too dry air can cause the fiber to become brittle and break, while too humid air will not dry the fiber sufficiently.

Flow rate:

- The flow rate of the drying air must be controlled to ensure that the fiber is exposed to the hot air for the correct amount of time.

- Too high a flow rate can cause the fiber to be dried too quickly and unevenly, while too low a flow rate will not dry the fiber sufficiently.

3. What are the common problems that can occur during the drying process and how can they be solved?

- Over-drying: This can occur if the fiber is exposed to the hot air for too long or at too high a temperature. It can cause the fiber to become brittle and break.

- Under-drying: This can occur if the fiber is not exposed to the hot air for long enough or at a high enough temperature. It can cause the fiber to remain wet and moldy.

- Uneven drying: This can occur if the fiber is not exposed to the hot air evenly. It can cause some parts of the fiber to be over-dried while other parts are under-dried.

4. What is the role of a fiber drier operator?

- Monitor and control the drying process to ensure that the fiber is dried properly.

- Make adjustments to the dryer settings as needed to maintain the desired drying conditions.

- Inspect the fiber after drying to ensure that it meets the required specifications.

- Maintain and troubleshoot the dryer to prevent breakdowns.

5. What are the safety precautions that need to be taken when operating a fiber drier?

- Wear appropriate personal protective equipment, such as gloves, safety glasses, and a respirator.

- Keep the work area clean and free of debris.

- Do not operate the dryer if it is damaged or malfunctioning.

- Follow all manufacturer’s instructions for safe operation.

6. How do you ensure that the fiber is dried to the correct moisture content?

- Use a moisture meter to measure the moisture content of the fiber after drying.

- Compare the moisture content to the desired specifications.

- Adjust the dryer settings as needed to achieve the desired moisture content.

7. What are the different methods of loading and unloading the fiber drier?

- Manual loading and unloading: This involves manually loading the fiber into the dryer and unloading it after it has been dried.

- Mechanical loading and unloading: This involves using a conveyor or other mechanical device to load and unload the fiber.

- Pneumatic loading and unloading: This involves using a vacuum or compressed air to load and unload the fiber.

8. What are the maintenance tasks that need to be performed on a fiber drier?

- Clean the dryer regularly to remove any dust or debris.

- Inspect the dryer for any damage or wear and tear.

- Lubricate the dryer’s moving parts.

- Calibrate the dryer’s temperature and humidity sensors.

9. What are the troubleshooting steps that you would take if the fiber drier is not working properly?

- Check the dryer’s power supply to make sure that it is turned on.

- Check the dryer’s settings to make sure that they are correct.

- Inspect the dryer for any damage or wear and tear.

- Contact the manufacturer’s technical support for assistance.

10. What are the qualities of a good fiber drier operator?

- Attention to detail

- Ability to follow instructions

- Problem-solving skills

- Mechanical aptitude

- Teamwork skills

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Fiber Drier Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Fiber Drier Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Fiber Drier Operator is responsible for ensuring the efficient and safe operation of a fiber dryer machine. The key responsibilities include:

1. Machine Operation

Operate fiber dryer machine to dry and cure fiber materials according to established procedures.

- Monitor and adjust machine settings, such as temperature, speed, and tension, to achieve optimal drying results.

- Load and unload fiber materials onto the machine conveyor system.

2. Quality Control

Inspect and assess the dried fiber materials for quality and consistency.

- Conduct routine tests to ensure that the fiber meets required specifications.

- Identify and resolve any quality issues that may arise during the drying process.

3. Equipment Maintenance

Perform routine maintenance and cleaning on the fiber dryer machine to ensure its proper functioning.

- Follow established maintenance schedules to lubricate, adjust, and repair machine components.

- Identify and troubleshoot minor equipment malfunctions and take corrective actions.

4. Safety Compliance

Maintain a safe work environment by adhering to all safety regulations and procedures.

- Wear appropriate personal protective equipment (PPE) at all times.

- Follow proper lockout/tagout procedures when working on the machine.

Interview Tips

To ace an interview for a Fiber Drier Operator position, consider the following tips:

1. Research the Company and Role

Thoroughly research the company and the specific role to gain insights into its operations, culture, and expectations.

- Visit the company’s website and social media pages for information.

- Read industry publications and news articles to understand the company’s position in the market.

2. Highlight Relevant Skills and Experience

Emphasize your skills and experience that directly align with the key responsibilities of a Fiber Drier Operator.

- Quantify your accomplishments using specific metrics to demonstrate your impact.

- Provide examples of how you have successfully handled similar responsibilities in previous roles.

3. Demonstrate Safety Awareness

Highlight your commitment to maintaining a safe work environment.

- Describe your understanding of relevant safety regulations and industry best practices.

- Share examples of how you have implemented safety measures in your previous roles.

4. Ask Insightful Questions

Prepare thoughtful questions to ask the interviewer.

- Inquire about the company’s growth plans and industry outlook.

- Ask about the specific challenges and opportunities associated with the role.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Fiber Drier Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!