Are you gearing up for an interview for a Field Ring Assembler position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Field Ring Assembler and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

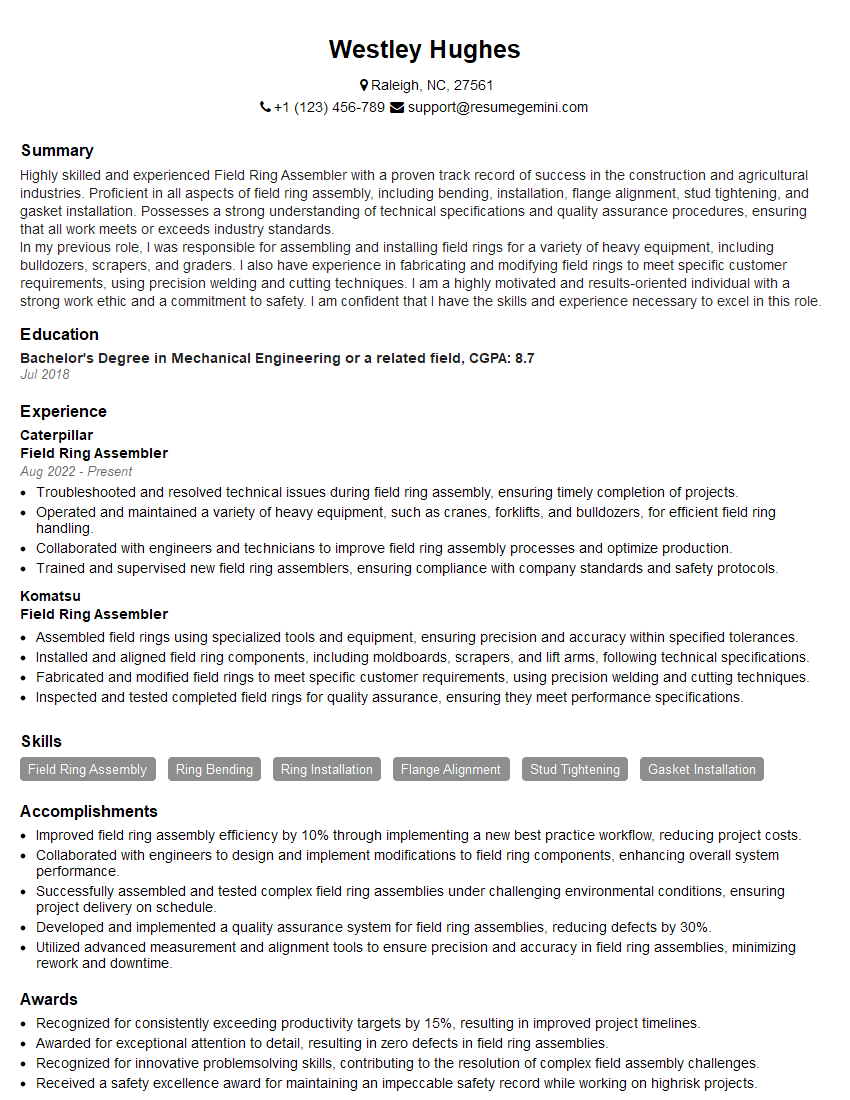

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Field Ring Assembler

1. Explain the process of assembling a field ring?

Here is a detailed breakdown of the process of assembling a field ring:

- Gather the necessary materials, including the ring base, ring mats, corner pads, ring ropes, and turnbuckles.

- Lay out the ring base on a flat surface and assemble the corner pads.

- Place the ring mats on top of the corner pads and secure them with the turnbuckles.

- Attach the ring ropes to the turnbuckles and tension them until they are taut.

- Inspect the ring to ensure that it is stable and secure before use.

2. What are the safety precautions that must be taken when assembling a field ring?

Safety First: Ensuring a Safe Assembly

- Wear appropriate safety gear, such as gloves and safety glasses.

- Ensure that the work area is clear of obstacles and hazards.

- Inspect the ring components for any damage or defects before assembly.

- Use proper lifting techniques when handling heavy components

- Do not attempt to assemble the ring alone; always work with a partner.

Ongoing Maintenance: Staying Safe

- Inspect the ring regularly for any signs of wear or damage.

- Tighten the ring ropes as needed to maintain tension.

- Replace any damaged components immediately.

- Store the ring in a dry and protected location when not in use.

3. What are the different types of field rings and their uses?

Field rings come in various types, each designed for specific purposes:

- Standard Wrestling Ring: The most common type, used for professional wrestling events.

- Boxing Ring: Smaller than a wrestling ring, with a raised platform and padded ropes.

- MMA Cage: Enclosed structure with chain-link fencing and a canvas mat, used for mixed martial arts fights.

- Grappling Ring: Designed for submission grappling competitions, with a smaller size and no ropes.

- Portable Ring: Lightweight and easy to assemble, suitable for events with limited setup time and space.

4. How do you troubleshoot common problems that may arise during field ring assembly?

Troubleshooting common problems ensures a smooth assembly process:

- Loose Ropes: Tighten the turnbuckles to increase tension.

- Uneven Ring Surface: Adjust the height of the corner pads to level the mats.

- Damaged Components: Replace any damaged parts immediately to maintain safety.

- Assembly Difficulties: Refer to the manufacturer’s instructions or seek assistance from an experienced assembler.

- Ring Instability: Check the stability of the ring base and corner pads. Ensure that all components are securely fastened.

5. What is the importance of maintaining a field ring?

Regular maintenance is crucial for the safety and longevity of the field ring:

- Safety: A well-maintained ring minimizes the risk of injuries to wrestlers or fighters.

- Durability: Proper maintenance extends the lifespan of the ring and its components.

- Appearance: A clean and well-maintained ring enhances the overall presentation of the event.

- Compliance: Regular maintenance helps ensure compliance with safety regulations and industry standards.

6. Describe the different types of tools used in field ring assembly.

Various tools are essential for efficient and effective field ring assembly:

- Wrenches: For tightening and loosening turnbuckles and other connections.

- Screwdrivers: For assembling and disassembling components.

- Allen Keys: For adjusting and securing bolts.

- Level: For ensuring that the ring surface is even.

- Measuring Tape: For accurate measurements and alignment.

7. Explain the procedure for disassembling a field ring.

Disassembling a field ring is equally important as assembling it:

- Safety First: Wear appropriate safety gear and ensure a clear work area.

- Remove Ropes: Detach the ring ropes from the turnbuckles.

- Disassemble Mats: Remove the ring mats from the corner pads.

- Unscrew Turnbuckles: Loosen and remove the turnbuckles from the corner pads.

- Store Components: Carefully store all components in a dry and protected location.

8. Discuss the importance of following safety regulations when assembling and disassembling a field ring.

Safety is paramount throughout the process:

- Prevent Injuries: Adhering to safety regulations minimizes the risk of accidents and injuries.

- Legal Compliance: Following regulations ensures compliance with industry standards and legal requirements.

- Equipment Protection: Proper handling and storage practices extend the lifespan of the ring and its components.

- Professionalism: Demonstrating a commitment to safety enhances credibility and professionalism.

9. What are the common challenges faced during field ring assembly and how do you overcome them?

Challenges are inevitable, but preparation is key:

- Uneven Surfaces: Adjust the height of the corner pads to level the mats.

- Damaged Components: Replace any damaged parts immediately.

- Time Constraints: Plan ahead, gather necessary tools, and work efficiently.

- Complex Installations: Refer to manufacturer’s instructions, seek assistance from experienced assemblers, or consult with the venue.

- Weather Conditions: Monitor weather forecasts and have contingency plans for outdoor assemblies.

10. How do you ensure the quality and safety of a field ring after assembly?

Quality and safety go hand in hand:

- Thorough Inspection: Check all components for damage or defects before and after assembly.

- Proper Tensioning: Ensure that the ring ropes are taut and evenly tensioned.

- Stability: Test the stability of the ring by applying pressure to different areas.

- Documentation: Keep records of inspections and maintenance performed for traceability and compliance.

- Continuous Monitoring: Regularly inspect the ring for any signs of wear or damage, and address issues promptly.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Field Ring Assembler.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Field Ring Assembler‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Field Ring Assemblers play a crucial role in the construction and maintenance of wind turbine generators. Their primary responsibilities include:

1. Assembly and Installation

Assembling and installing components of wind turbine generators, ensuring proper alignment and functionality.

- Assembling the wind turbine tower, nacelle, and blades following blueprints and specifications.

- Installing electrical and mechanical components, such as generators, transformers, and control systems.

2. Troubleshooting and Repairs

Diagnosing and resolving technical issues in wind turbine generators to ensure optimal performance and safety.

- Identifying and rectifying electrical, mechanical, and hydraulic problems in various turbine components.

- Performing maintenance and repair tasks on wind turbine blades, including patching, sanding, and re-coating.

3. Safety and Compliance

Adhering to strict safety regulations and environmental standards while working on wind turbine generators.

- Following established safety procedures during assembly, installation, and maintenance tasks.

- Ensuring that all work complies with regulatory requirements and industry best practices.

4. Communication and Teamwork

Collaborating with colleagues, supervisors, and other stakeholders to complete projects effectively.

- Communicating work status, potential issues, and project updates to team members and management.

- Coordinating with subcontractors and suppliers to ensure timely delivery of materials and services.

Interview Tips

Preparing thoroughly for a Field Ring Assembler interview can significantly increase your chances of success. Here are some tips to help you ace the interview:

1. Research the Company and Industry

Familiarize yourself with the company’s history, mission, and values, as well as the current trends and challenges in the wind energy industry.

- Visit the company website, read industry news articles, and check social media platforms for relevant information.

- Research the company’s competitors and their market position to demonstrate your understanding of the industry landscape.

2. Highlight Your Technical Skills

Emphasize your technical expertise and experience in assembling and installing wind turbine generators.

- Quantify your accomplishments by providing specific examples of projects you have worked on, the challenges you faced, and the solutions you implemented.

- Demonstrate your proficiency in using specialized tools and equipment, such as cranes, lifts, and torque wrenches.

3. Showcase Your Safety and Compliance Knowledge

Highlight your understanding of safety regulations and your commitment to adhering to industry best practices.

- Explain your experience in following established safety protocols, such as wearing appropriate PPE, using fall protection equipment, and working in confined spaces.

- Mention your knowledge of environmental regulations and your commitment to sustainability.

4. Practice Your Communication Skills

Be prepared to effectively communicate your ideas, both verbally and in writing.

- Practice answering common interview questions clearly and concisely, using specific examples to support your answers.

- Prepare questions to ask the interviewer, demonstrating your interest in the company and the position.

5. Dress Professionally and Arrive on Time

First impressions matter, so dress appropriately for the interview and arrive on time to show respect for the hiring manager.

- Wear clean, pressed clothing that is appropriate for the job setting.

- Be punctual and arrive at the interview location well before the scheduled time.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Field Ring Assembler interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!