Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Filament Welder interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Filament Welder so you can tailor your answers to impress potential employers.

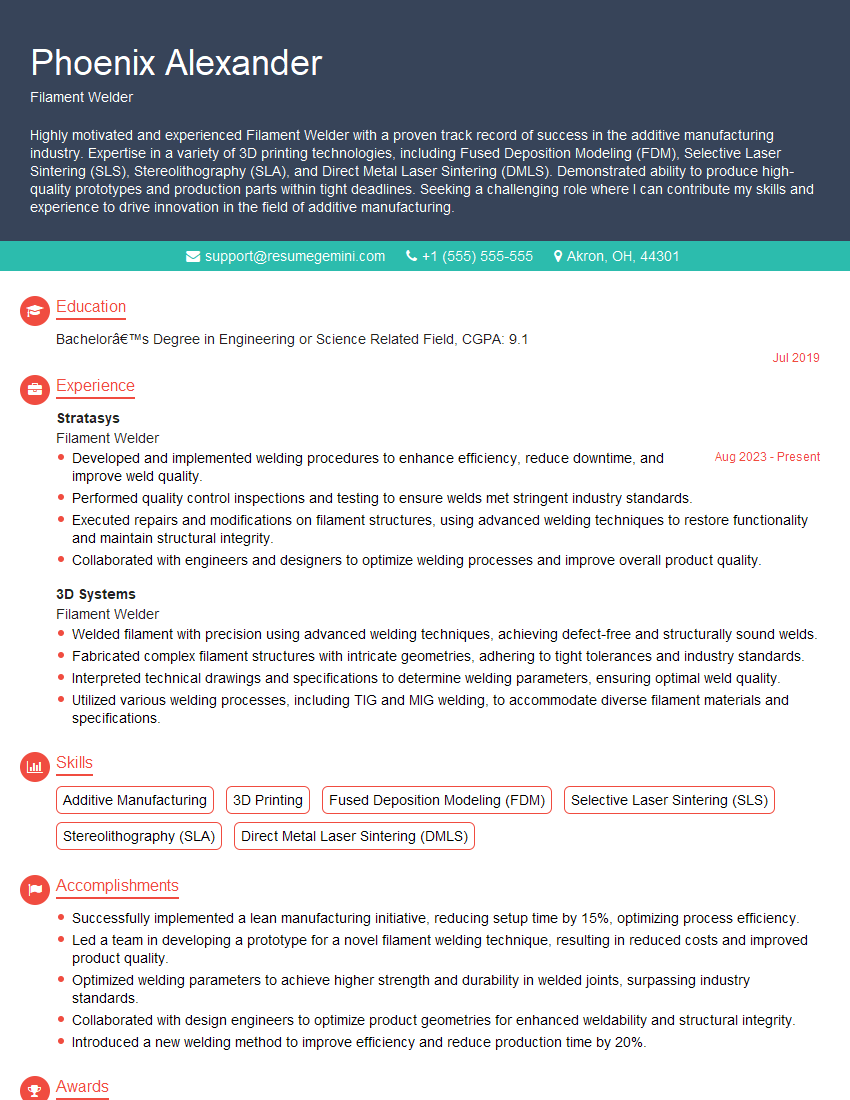

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Filament Welder

1. What are the different types of filament welding?

There are three main types of filament welding:

- Hot Plate Welding: Involves heating a metal plate and placing the filaments on it, and then pressing them together to bond them.

- Impulse Welding: Involves using a heated filament to create a weld between two pieces of metal.

- Ultrasonic Welding: Involves using high-frequency sound waves to create a weld between two pieces of metal.

2. What are the advantages and disadvantages of filament welding?

Advantages

- High strength and durability

- Low cost

- Fast and efficient

Disadvantages

- Can only be used on certain types of metals

- Requires specialized equipment

- Can be difficult to control the weld quality

3. What are the safety precautions that must be taken when filament welding?

There are several safety precautions that must be taken when filament welding, including:

- Always wear appropriate personal protective equipment (PPE), including safety glasses, gloves, and a welding helmet.

- Ensure that the welding area is well-ventilated to avoid inhaling harmful fumes.

- Never weld near flammable materials.

- Be aware of the potential for electrical shock and take proper precautions.

- Follow all manufacturer’s instructions for the specific welding equipment being used.

4. What are the different types of materials that can be filament welded?

Filament welding can be used with various materials, including:

- Metals: Steel, aluminum, copper, brass, and titanium

- Plastics: ABS, PVC, polyethylene, and polypropylene

- Ceramics: Alumina, zirconia, and silicon carbide

5. What is the difference between a filament welder and a spot welder?

- Filament welder uses a continuous filament of metal to create a weld, while a spot welder uses two electrodes to create a weld at a specific point.

- Filament welding is typically used for larger welds, while spot welding is used for smaller welds.

- Filament welding is more versatile than spot welding, as it can be used on a wider variety of materials.

6. What are the different factors that affect the quality of a filament weld?

- Type of material being welded

- Thickness of the material

- Welding temperature

- Welding speed

- Welding pressure

7. How do you troubleshoot a filament welding machine?

Troubleshooting a filament welding machine involves identifying the problem and finding a solution. Some common problems and their solutions include:

- No power: Check the power cord and make sure the machine is plugged in.

- No heat: Check the heating element and make sure it is properly connected.

- Poor weld quality: Check the welding parameters and make sure they are set correctly.

8. What are the latest advancements in filament welding technology?

Some of the latest advancements in filament welding technology include:

- Improved welding speed and efficiency

- Better weld quality and consistency

- New materials and applications

9. What are the career opportunities for filament welders?

Filament welders are in high demand in various industries, including:

- Manufacturing

- Automotive

- Aerospace

- Construction

10. What are the qualifications and experience required to become a filament welder?

Typically, filament welders need the following qualifications and experience:

- High school diploma or equivalent

- Completion of a welding training program

- Experience in filament welding

- Knowledge of welding codes and standards

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Filament Welder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Filament Welder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

1. Welding and Fabrication

Weld and fabricate components, such as pipes, fittings and tanks, according to established procedures and specifications.

- Set up and operate various welding equipment, including TIG and MIG welders.

- Inspect and prepare surfaces for welding, ensuring proper joint preparation and cleanliness.

- Follow welding procedures and specifications, including weld thickness, penetration, and joint geometry.

2. Equipment Maintenance

Maintain and calibrate welding equipment, ensuring it operates safely and efficiently.

- Regularly clean and inspect welding equipment, including torches, nozzles, and gas regulators.

- Troubleshoot and resolve welding equipment issues, performing basic repairs and adjustments.

3. Safety and Compliance

Adhere to safety regulations and industry standards, ensuring a safe work environment.

- Wear appropriate personal protective equipment (PPE), including a welding helmet, gloves, and flame-resistant clothing.

- Follow established safety protocols, including proper ventilation, fire prevention, and hazardous material handling.

- Maintain a clean and organized work area, eliminating potential hazards.

- Stay updated on industry best practices and safety regulations.

4. Quality Control

Inspect and test welded products to ensure they meet quality standards.

- Conduct visual and non-destructive testing (NDT) methods, such as radiographic and ultrasonic testing, to verify the integrity of welds.

- Report any defects or irregularities to supervisors immediately.

- Participate in continuous improvement initiatives to enhance quality standards.

Interview Tips

Preparing for a filament welder interview can help you present your skills and experience effectively. Here are some tips to ace the interview:

1. Research the Company and Position

Gather information about the company, its products or services, and the specific role you are applying for. This will help you better understand the company’s needs and demonstrate your interest in the position.

2. Practice Your Welding Techniques

Refresh your welding skills and practice on a variety of materials to showcase your proficiency. This will show the interviewer that you are confident in your abilities and ready to contribute to their team.

3. Highlight Your Safety Knowledge

Welding can be a hazardous profession, so emphasizing your safety knowledge and compliance is crucial. Be familiar with industry regulations and best practices, and demonstrate your commitment to maintaining a safe work environment.

4. Showcase Your Attention to Detail

Filament welding requires precision and attention to detail. Prepare examples that showcase your ability to follow specifications, inspect welds, and ensure quality.

5. Be Prepared for Technical Questions

Expect technical questions about welding equipment, materials, and techniques. Review common welding processes, weld joint designs, and industry standards to prepare for these questions.

6. Dress Professionally and Arrive on Time

First impressions matter, so dress professionally for the interview. Additionally, arriving on time shows respect for the interviewer and demonstrates your punctuality.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Filament Welder interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!