Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Fitter-Welder position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

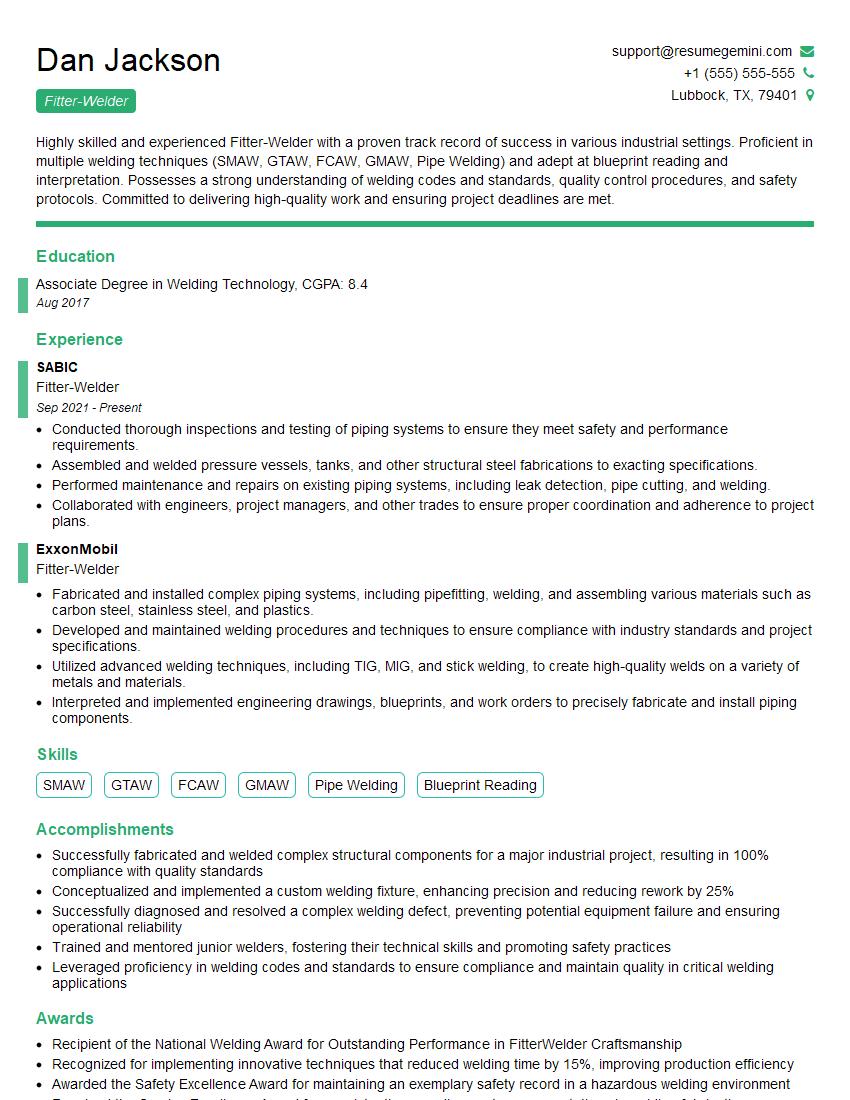

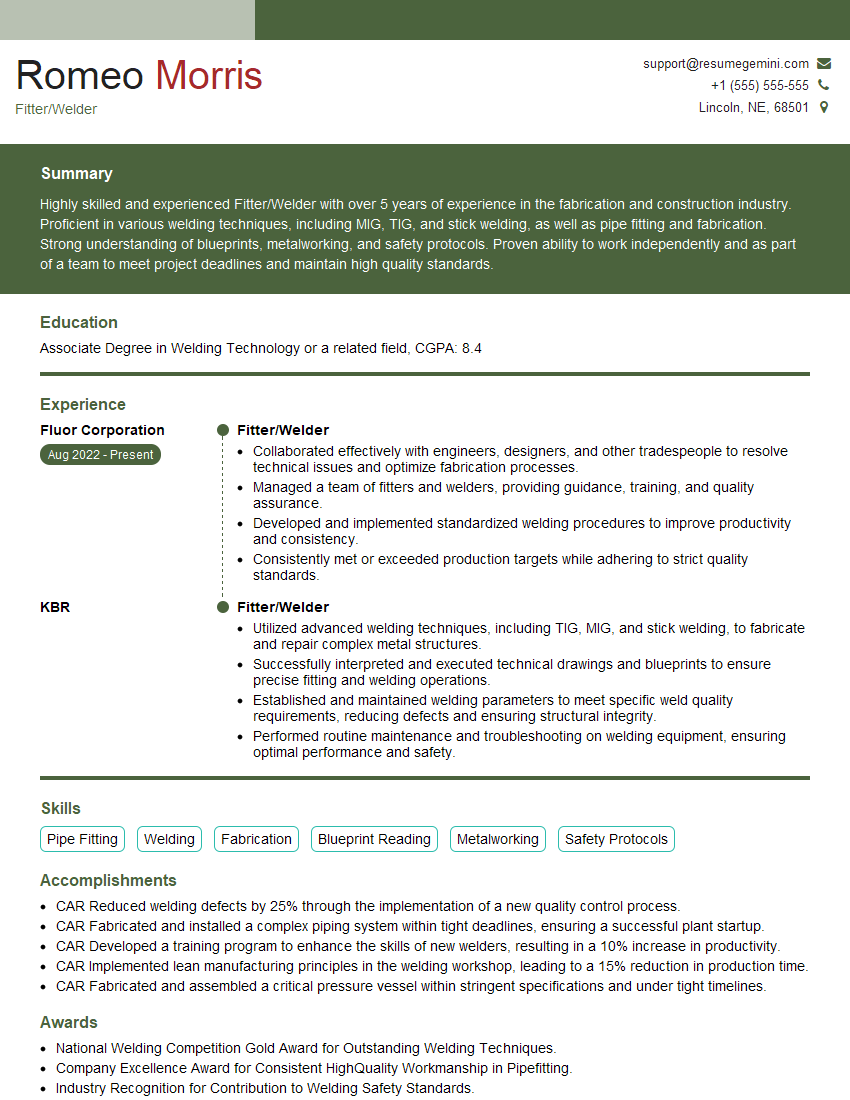

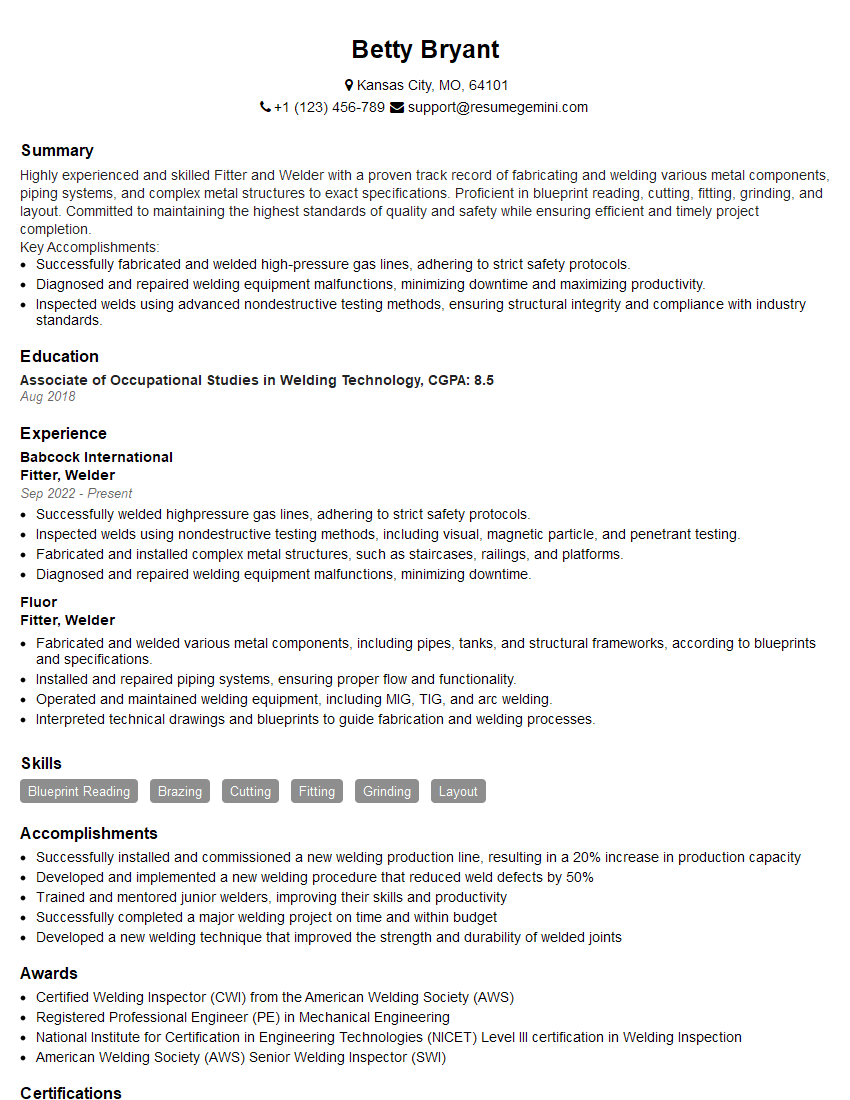

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Fitter-Welder

1. Explain the different welding techniques you are familiar with?

I have experience in various welding techniques, including:

- Arc Welding:

- Gas Tungsten Arc Welding (GTAW)

- Gas Metal Arc Welding (GMAW)

- Shielded Metal Arc Welding (SMAW)

- Resistance Welding:

- Spot Welding

- Projection Welding

2. What is the difference between tack welding and fusion welding?

Tack Welding

- Temporary, small welds used to hold pieces together during alignment

- Not designed to carry significant loads

Fusion Welding

- Permanent, stronger welds that fuse the metal pieces together

- Carry significant loads and create a structurally sound joint

3. Describe the steps involved in preparing a welding joint?

The steps involved in preparing a welding joint include:

- Cleaning the surfaces to remove any contaminants or oxides

- Beveling the edges of the joint to create a proper fit-up

- Clamping the pieces together to ensure proper alignment

- Applying any necessary backing materials or shielding gases

4. How do you determine the correct welding parameters, such as voltage, amperage, and travel speed?

To determine the correct welding parameters, I consider several factors, including:

- Material thickness

- Type of welding process

- Joint design

- Filler material selection

5. What safety precautions should be taken when operating welding equipment?

When operating welding equipment, it is crucial to take the following safety precautions:

- Wearing appropriate personal protective equipment (PPE), including welding helmet, gloves, and fire-resistant clothing

- Ensuring proper ventilation to avoid exposure to welding fumes

- Inspecting equipment regularly for any defects or damage

- Storing and handling welding materials and gases safely

6. Explain the importance of post-weld heat treatment?

Post-weld heat treatment is used to improve the mechanical properties of the welded joint by:

- Reducing residual stresses

- Enhancing toughness and ductility

- Improving fatigue strength

7. What inspection methods are used to verify the quality of welded joints?

To verify the quality of welded joints, various inspection methods are employed, such as:

- Visual inspection

- Radiographic testing (X-ray or gamma ray)

- Ultrasonic testing

- Magnetic particle testing

- Liquid penetrant testing

8. Describe the different types of welding defects and how to avoid them?

Common welding defects include:

- Porosity: Caused by entrapped gases during welding

- Incomplete fusion: Occurs when the weld metal does not fully fuse to the base metal

- Undercut: A groove formed along the base metal adjacent to the weld

- Cracks: Can be caused by excessive stresses or improper welding technique

To avoid these defects, proper preparation, welding technique, and quality control measures are critical.

9. What are some of the challenges you have encountered in welding and how did you overcome them?

One challenge I faced was welding complex, thick-walled components. To overcome this, I used a multi-pass welding technique, ensuring proper penetration and avoiding overheating.

Another challenge involved working in confined spaces. I addressed this by carefully planning the sequence of operations and using specialized tools and equipment.

10. What are your strengths and weaknesses as a Welder?

Strengths:

- Proficient in various welding techniques

- Excellent attention to detail and precision

- Strong ability to read and interpret blueprints and specifications

Weaknesses:

- Limited experience in exotic materials welding

- Working independently for extended periods can be challenging

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Fitter-Welder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Fitter-Welder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Fitter-Welders play a crucial role in various industries, utilizing their skills to fabricate, assemble, and repair metal structures and components. Their responsibilities encompass a wide range of tasks, including:

1. Fabrication and Assembly

Fitter-Welders are responsible for fabricating and assembling metal structures according to blueprints and specifications. This involves:

- Cutting, shaping, and bending metal using various tools and equipment

- Assembling and fitting different metal components together

- Ensuring proper alignment and fit of the assembled components

2. Welding

Fitter-Welders use different welding techniques to join metal components permanently. This includes:

- Arc welding, including TIG, MIG, and stick welding

- Plasma welding

- Gas welding

- Soldering and brazing

3. Inspection and Testing

After fabrication and welding, Fitter-Welders conduct inspections and tests to ensure the quality and integrity of the assembled structures. This involves:

- Visual inspections for any defects or imperfections

- Dimensional measurements to verify adherence to specifications

- Pressure testing for vessels or piping systems

- Strength testing to ensure the structural integrity of the welded joints

4. Maintenance and Repair

Fitter-Welders are also responsible for maintaining and repairing existing metal structures and equipment. This includes:

- Identifying and diagnosing faults or failures

- Performing repairs using appropriate welding techniques

- Ensuring the safety and functionality of the repaired structures

Interview Tips

Preparing for a Fitter-Welder interview requires thorough research and practice. Here are some tips to help candidates ace the interview:

1. Research the Company and Industry

Candidates should thoroughly research the company they are applying to, as well as the industry they will be working in. This knowledge demonstrates their interest in the position and their understanding of the company’s operations.

2. Practice Welding Skills

Fitter-Welders should practice their welding skills to demonstrate their proficiency in various welding techniques. This could involve setting up a mock welding station and practicing welding different types of metals and joints.

3. Review Technical Knowledge

Candidates should review their technical knowledge of welding processes, metal fabrication, and inspection methods. This knowledge is essential for understanding the interviewer’s questions and demonstrating their expertise in the field.

4. Prepare for Safety Questions

Safety is paramount in welding environments. Candidates should prepare for questions related to their knowledge of welding safety procedures, personal protective equipment, and emergency protocols.

5. Showcase Industry Experience

Highlighting relevant work experience and projects is crucial. Candidates should provide specific examples of their involvement in fabrication and welding projects, emphasizing their accomplishments and contributions.

6. Be Prepared for Behavioral Questions

Interviewers may ask behavioral questions to assess the candidate’s problem-solving skills, teamwork abilities, and work ethic. Candidates should prepare anecdotes or examples that demonstrate their strengths in these areas.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Fitter-Welder interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.