Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Foam Rubber Mixer position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Foam Rubber Mixer

1. What are the key steps involved in the foam rubber mixing process?

In foam rubber mixing, key steps include:

- Selecting and weighing raw materials accurately

- Mixing components in the correct proportions using a high-speed mixer

- Controlling mixing time and temperature to achieve the desired foam properties

- Pouring the mixed material into a mold and allowing it to expand and cure

- Post-processing steps like trimming, shaping, and testing to ensure quality

2. How do you ensure the consistency and quality of the foam rubber products?

Maintaining Equipment and Calibration:

- Regularly calibrate and maintain mixing machines to ensure accurate mixing ratios

- Inspect and clean equipment thoroughly to prevent contamination

Raw Material Management:

- Source high-quality raw materials from reliable suppliers

- Conduct incoming inspections to verify specifications and consistency

Process Control:

- Follow standardized mixing procedures and monitor key parameters like temperature and mixing time

- Use statistical process control techniques to track and adjust variables as needed

3. What are the different types of foam rubber, and how are their properties tailored for specific applications?

Types of foam rubber include:

- Polyurethane foam: Rigid or flexible, used in insulation, cushioning, and packaging

- Polystyrene foam: Lightweight and buoyant, used in packaging and disposable products

- EPDM foam: Resistant to ozone and UV radiation, used in outdoor applications and automotive parts

- Neoprene foam: Oil- and chemical-resistant, used in marine and industrial applications

Properties are tailored by adjusting factors such as:

- Density and cell structure

- Type and amount of blowing agent

- Additives like flame retardants or antimicrobial agents

4. How do you troubleshoot common problems that arise during the foam rubber mixing process?

Common problems and troubleshooting steps include:

- Inconsistent foam density: Calibrate mixing equipment, check raw material ratios, and adjust mixing time

- Poor cell structure: Optimize blowing agent concentration, adjust mixing temperature, and ensure proper mold design

- Defects or imperfections: Inspect equipment for wear or damage, check for contamination, and review mixing procedures

- Excessive shrinkage or expansion: Adjust mixing parameters, check curing conditions, and consider using different additives

5. What safety precautions are essential when working with foam rubber mixing equipment?

- Wear appropriate personal protective equipment (PPE) like gloves, safety glasses, and a respirator

- Follow proper operating procedures to avoid hazards like spills or burns

- Be aware of potential chemical hazards and have a spill response plan in place

- Maintain a clean and organized work area to prevent accidents

- Receive training on safety protocols and emergency procedures

6. How do you stay updated on the latest advancements and trends in foam rubber mixing technology?

- Attend industry conferences, workshops, and training programs

- Read technical journals and publications

- Network with other professionals in the field

- Research and explore new materials, processes, and equipment

- Collaborate with suppliers and manufacturers to gain insights into innovative solutions

7. What is the role of a blowing agent in foam rubber production, and what factors affect its selection?

A blowing agent creates the gas bubbles that give foam rubber its unique properties.

Factors affecting selection:

- Desired foam density

- Processing temperature

- Compatibility with other materials

- Environmental and safety regulations

8. Describe the curing process for foam rubber and explain how it influences the final product properties.

- Cross-linking: Chemical reactions form bonds between polymer chains, increasing strength and stability

- Temperature and time: Controlled conditions optimize curing and prevent defects

- Curing agents: Additives accelerate or initiate curing reactions

- Final properties: Curing affects factors like hardness, elasticity, and durability

9. What are the environmental considerations involved in foam rubber production, and how can they be addressed?

- Raw material sourcing: Use sustainable and recycled materials

- Energy efficiency: Optimize mixing and curing processes

- Waste management: Implement waste reduction and recycling programs

- Emissions control: Use environmentally friendly blowing agents and minimize VOCs

- Compliance with regulations: Adhere to local and international environmental standards

10. How do you ensure the safety and quality of foam rubber products intended for use in critical applications, such as automotive or medical devices?

- Rigorous testing: Conduct thorough inspections and performance tests to meet industry standards

- Traceability: Implement systems to track raw materials and production batches

- Supplier qualification: Partner with reliable suppliers who meet quality requirements

- Quality assurance program: Establish and maintain a comprehensive quality management system

- Regulatory compliance: Obtain necessary certifications and meet regulatory requirements

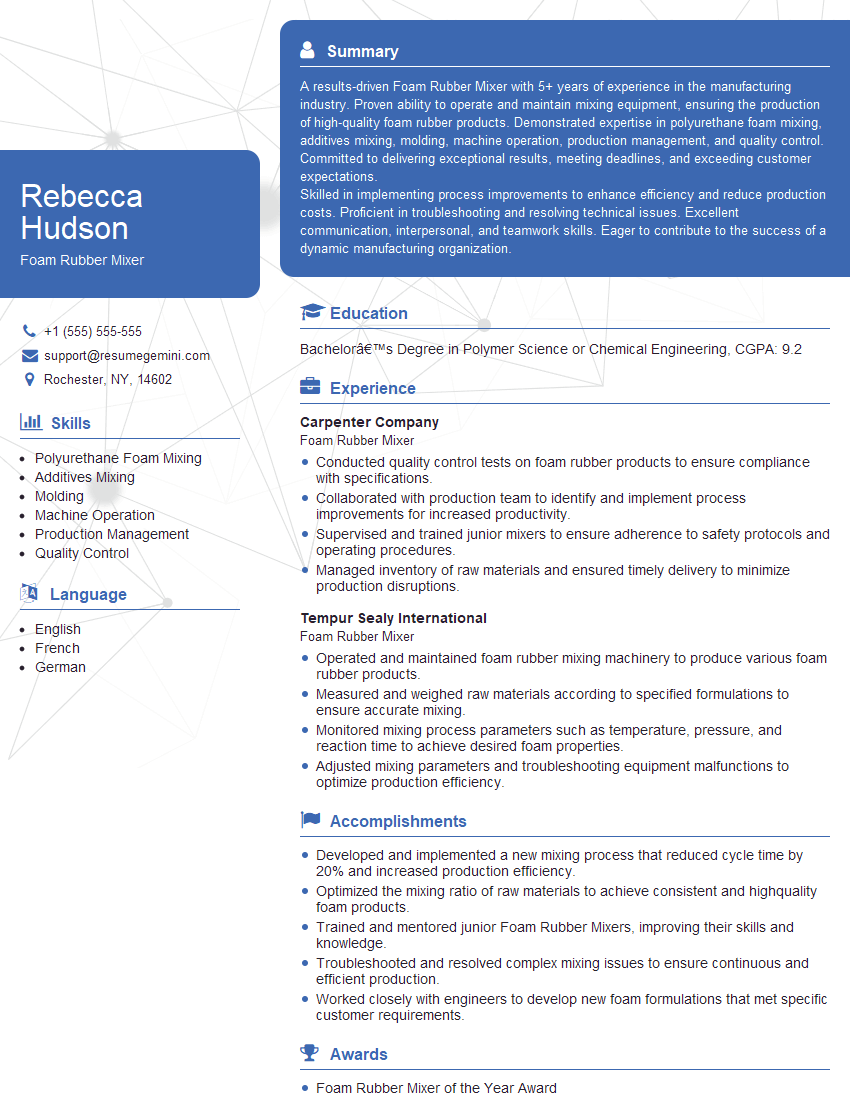

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Foam Rubber Mixer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Foam Rubber Mixer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Foam Rubber Mixers are responsible for mixing and preparing foam rubber compounds, ensuring products meet required specifications. Their duties may include:

1. Materials Management

Acquiring and managing raw materials for foam rubber production.

2. Mixing Operations

Mixing raw materials, including chemicals, fillers, and blowing agents, according to formulas.

Controlling mixing processes, including time, temperature, and pressure to achieve desired foam properties.

3. Quality Control

Monitoring and testing foam mixtures to ensure they meet specifications, such as density, porosity, and hardness.

Conducting physical tests, such as tensile strength, compression resistance, and elongation to ensure product quality.

4. Equipment Maintenance

Maintaining and cleaning mixing equipment to ensure optimal performance and safety.

Performing minor repairs and troubleshooting equipment issues.

Interview Tips

Preparing for an interview as a Foam Rubber Mixer requires understanding the role’s responsibilities and showcasing relevant skills.

1. Highlight Technical Expertise

Emphasize your knowledge of foam rubber mixing processes, raw materials, and testing methods.

Showcase your ability to operate and maintain mixing equipment efficiently.

2. Demonstrate Quality Control Skills

Explain your experience in conducting quality control tests and interpreting results.

Discuss your understanding of foam rubber specifications and the importance of adhering to them.

3. Stress Safety Procedures

Highlight your knowledge of safety protocols related to handling chemicals and operating mixing equipment.

Explain your experience in following safety guidelines and maintaining a clean and organized work environment.

4. Prepare Examples of Problem-Solving

Share examples of how you solved problems in previous positions, such as resolving equipment issues or ensuring product quality.

Describe your approach to troubleshooting and your ability to work effectively under pressure.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Foam Rubber Mixer interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!