Are you gearing up for an interview for a Four-Slide Machine Setter position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Four-Slide Machine Setter and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

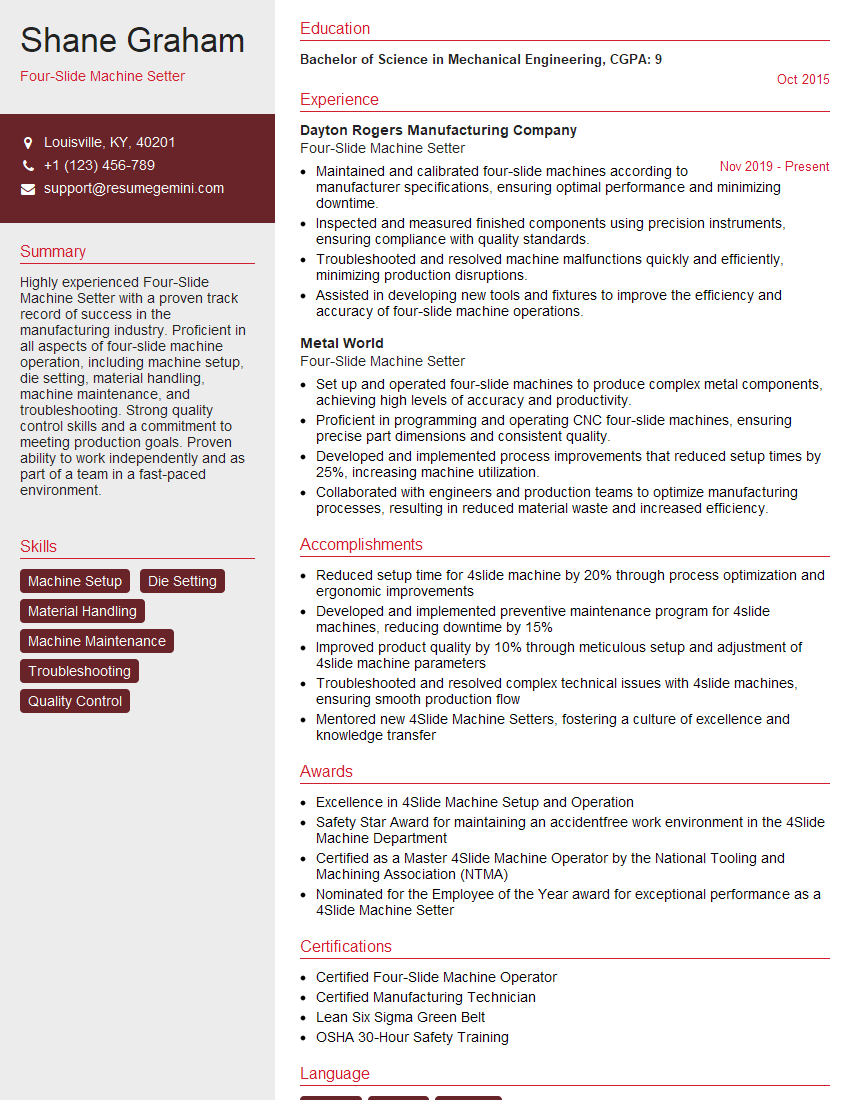

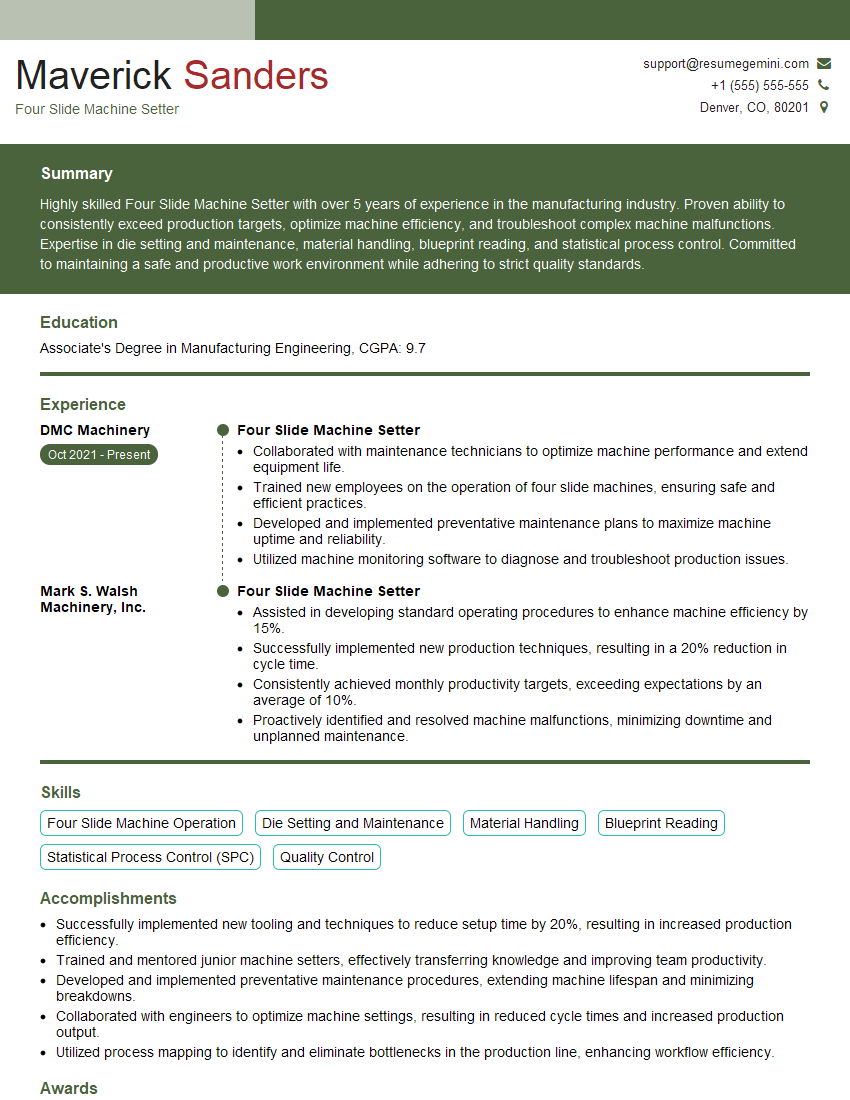

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Four-Slide Machine Setter

1. How do you set up and calibrate a four-slide machine?

I begin by ensuring the machine is level and properly lubricated. Next, I install the tooling and adjust the slides to the correct positions. I then calibrate the machine’s sensors and gauges to ensure accuracy. Finally, I run a test batch of parts to verify the machine is functioning correctly.

2. What are the different types of slides used in a four-slide machine?

Vertical slides

- Move up and down

- Used for forming and cutting operations

Horizontal slides

- Move left and right

- Used for feeding and transferring material

Angular slides

- Move at an angle

- Used for complex forming operations

3. What are the safety precautions that should be taken when operating a four-slide machine?

- Wear appropriate safety gear, including eye protection, gloves, and earplugs

- Keep hands and loose clothing away from moving parts

- Never operate the machine while under the influence of drugs or alcohol

- Follow all manufacturer’s instructions and safety guidelines

4. How do you troubleshoot common problems with a four-slide machine?

- Check for loose or worn parts

- Inspect the tooling for damage or wear

- Calibrate the machine’s sensors and gauges

- Check the hydraulic and electrical systems for leaks or faults

5. What is the role of a Four-Slide Machine Setter?

A Four-Slide Machine Setter is responsible for setting up, maintaining, and troubleshooting four-slide machines. They ensure that the machines are operating safely and efficiently, and that they are producing high-quality parts.

6. What are the key skills and knowledge required to be a successful Four-Slide Machine Setter?

- Knowledge of four-slide machine operations

- Experience with setting up, maintaining, and troubleshooting four-slide machines

- Ability to read and interpret blueprints and technical drawings

- Strong mechanical aptitude

- Excellent problem-solving skills

7. What are the different types of materials that can be processed on a four-slide machine?

- Steel

- Stainless steel

- Aluminum

- Brass

- Copper

8. What are the different types of tools that can be used on a four-slide machine?

- Forming tools

- Cutting tools

- Piercing tools

- Embossing tools

- Coining tools

9. What are the quality control procedures that should be followed when operating a four-slide machine?

- Inspect raw materials before processing

- Monitor machine operation during production

- Inspect finished parts for defects

- Maintain accurate records of production and quality control data

10. What are the preventive maintenance tasks that should be performed on a four-slide machine?

- Regularly lubricate all moving parts

- Inspect and clean the tooling

- Calibrate the machine’s sensors and gauges

- Check the hydraulic and electrical systems for leaks or faults

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Four-Slide Machine Setter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Four-Slide Machine Setter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Four-Slide Machine Setter is accountable for ensuring optimal performance of four-slide machines, specializing in complex metal component production.

1. Machine Setup and Operation

Configure and operate four-slide machines according to specifications, maintaining precise tool alignment and product dimensions.

- Load and secure tooling, including slides, dies, and cut-off mechanisms.

- Adjust machine parameters to achieve desired part tolerances and production rates.

2. Maintenance and Troubleshooting

Perform routine maintenance on machines, including lubrication, cleaning, and calibration.

- Diagnose and resolve machine malfunctions and breakdowns, ensuring timely repairs.

- Monitor machine performance and identify areas for improvement.

3. Quality Control

Inspect produced parts to verify dimensional accuracy, surface finish, and compliance with specifications.

- Identify and correct non-conforming parts, maintaining quality standards.

- Collaborate with quality control personnel to implement and maintain quality assurance processes.

4. Production Optimization

Analyze production processes and identify opportunities for efficiency improvements.

- Evaluate machine settings and tooling to optimize cycle times and reduce waste.

- Suggest and implement changes to enhance productivity and reduce production costs.

Interview Tips

To ace the interview for a Four-Slide Machine Setter position, it is crucial to prepare effectively and demonstrate your knowledge and skills.

1. Research the Company and Industry

Familiarize yourself with the company’s products, services, and industry trends.

- Visit the company website and explore their social media profiles.

- Read industry publications and news articles to stay updated on advancements.

2. Highlight Relevant Experience and Skills

Emphasize your hands-on experience with four-slide machines, including specific models and tooling.

- Quantify your accomplishments, using metrics to demonstrate the impact of your work.

- Showcase your ability to troubleshoot and resolve machine issues efficiently.

3. Prepare for Technical Questions

Review the job responsibilities and anticipate questions related to machine setup, maintenance, and production optimization.

- Practice describing your approach to problem-solving and your understanding of machine parameters.

- Consider preparing examples of successful troubleshooting experiences.

4. Demonstrate Soft Skills

Emphasize your teamwork, communication, and problem-solving abilities.

- Discuss your experience working in a production environment and collaborating with others.

- Highlight your ability to communicate clearly and effectively with colleagues and supervisors.

5. Ask Informed Questions

Prepare thoughtful questions that demonstrate your interest in the position and the company.

- Inquire about the company’s production goals and challenges.

- Ask about opportunities for professional growth and development.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Four-Slide Machine Setter interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!