Are you gearing up for a career in Four-Slide Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Four-Slide Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

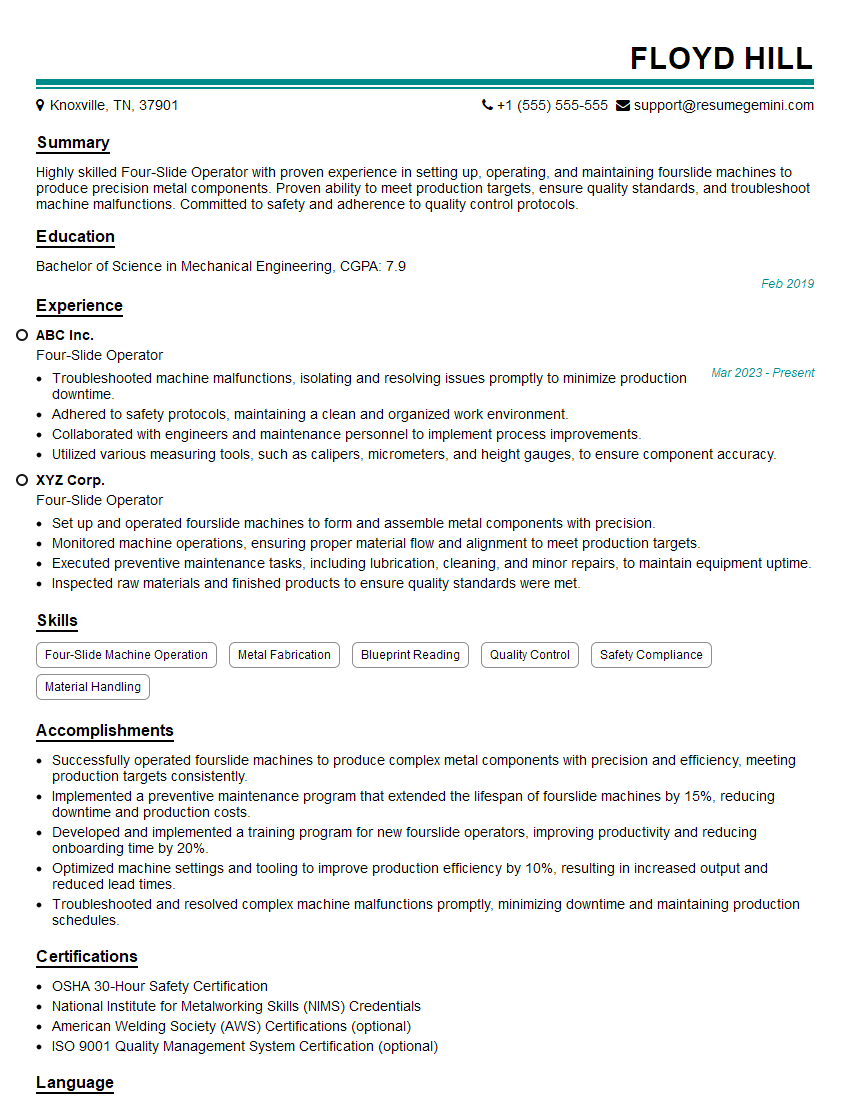

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Four-Slide Operator

1. What is the purpose of a four-slide operator?

A four-slide operator is responsible for operating a four-slide machine, which is a specialized type of metalforming equipment. This machine utilizes four slides to create complex shapes and forms in metal sheets and strips.

2. Describe the different types of four-slide machines.

There are two main types of four-slide machines:

- Horizontal four-slide machines: The slides move horizontally and are used for producing flat or slightly curved parts.

- Vertical four-slide machines: The slides move vertically and are used for producing complex three-dimensional parts.

3. What are the key components of a four-slide machine?

The key components of a four-slide machine include:

- Slides: These are the movable parts that perform the forming operations.

- Dies: These are the tools that shape the metal into the desired form.

- Feed mechanism: This mechanism controls the movement of the metal strip or sheet into the machine.

- Drive system: This system powers the machine and controls the movement of the slides.

4. What are the safety precautions that must be taken when operating a four-slide machine?

Safety precautions for operating a four-slide machine include:

- Always wear appropriate safety gear, including gloves, safety glasses, and earplugs.

- Keep the work area clean and free of debris.

- Never operate the machine with loose clothing or jewelry.

- Follow all manufacturer’s instructions and guidelines.

5. What types of materials can be processed on a four-slide machine?

Four-slide machines can process a wide range of materials, including:

- Steel

- Stainless steel

- Aluminum

- Brass

- Copper

6. What are the advantages of using a four-slide machine?

Four-slide machines offer several advantages, including:

- High precision and accuracy

- Ability to produce complex shapes and forms

- High production rates

- Reduced labor costs

7. What are the challenges of operating a four-slide machine?

Some challenges of operating a four-slide machine include:

- The need for specialized training and experience

- The potential for safety hazards

- The need for proper maintenance and calibration

- The high cost of the machine

8. How do you set up a four-slide machine?

Setting up a four-slide machine involves several steps, including:

- Installing the dies

- Adjusting the slide positions

- Calibrating the machine

- Testing the machine

9. How do you troubleshoot common problems with a four-slide machine?

Common problems with a four-slide machine and their troubleshooting steps include:

- Part jams: Check for misalignment of dies, incorrect feed rate, or dull dies.

- Poor part quality: Check for worn or damaged dies, incorrect machine settings, or material defects.

- Machine breakdowns: Refer to the manufacturer’s instructions and contact a qualified technician for assistance.

10. What are the latest trends in four-slide machine technology?

Recent trends in four-slide machine technology include:

- Increased automation

- Improved machine control systems

- The use of advanced materials and coatings

- Integration with other manufacturing processes

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Four-Slide Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Four-Slide Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Four-Slide Operator is responsible for operating and maintaining a four-slide machine. The primary aim is to shape and form metal components using a series of four slides and dies.

1. Machine Setup and Operation

The operator must be proficient in setting up and operating the four-slide machine, which involves:

- Installing and adjusting dies and tools

- Feeding metal coils or strips into the machine

- Monitoring the machine’s operation and adjusting settings to ensure optimal performance

2. Quality Control

The operator is responsible for inspecting and maintaining the quality of produced components, which includes:

- Checking dimensions and tolerances using precision measuring instruments

- Identifying and correcting any defects or inconsistencies

- Ensuring finished products meet required specifications

3. Maintenance and Troubleshooting

To ensure efficient operation, the operator must perform regular maintenance tasks, such as:

- Cleaning and lubricating the machine

- Replacing worn or damaged parts

- Diagnosing and troubleshooting any mechanical or electrical issues

4. Safety Procedures

The operator must adhere to all safety regulations and protocols, including:

- Wearing appropriate safety gear, such as gloves and safety glasses

- Following lockout/tagout procedures before performing maintenance

- Reporting any hazardous conditions or potential risks to supervisors

Interview Tips

To effectively prepare for an interview, candidates should consider the following tips:

1. Research the Company and Position

Familiarize yourself with the company’s background, products or services, and industry standing. Review the job description thoroughly, noting the specific responsibilities and qualifications required.

- Example Outline: “I thoroughly researched your company’s commitment to sustainable manufacturing practices, which aligns well with my own values and experience.”

2. Practice Your Answers

Prepare for common interview questions by practicing your responses. Consider using the STAR method (Situation, Task, Action, Result) to structure your answers and provide specific examples from your experience.

- Example Outline: “In my previous role, I successfully implemented a new quality control system that reduced product defects by 20%. Using the STAR method, I can demonstrate the specific steps I took, the challenges I faced, and the positive outcomes achieved.”

3. Highlight Relevant Skills and Experience

Emphasize your skills and experience that align with the job requirements. Quantify your accomplishments whenever possible, providing specific metrics or results to demonstrate your impact.

- Example Outline: “I have operated four-slide machines for over five years, consistently exceeding production targets and maintaining high-quality standards. In my previous role, I led a team of operators and implemented process improvements that increased efficiency by 15%.”

4. Be Ready to Ask Questions

Asking thoughtful questions during the interview shows your interest and engagement. Prepare questions that demonstrate your curiosity and understanding of the company and role.

- Example Outline: “I’m eager to learn more about your company’s plans for expanding into new markets. Can you share insights into the growth strategy and how this role would contribute to that vision?”

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Four-Slide Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.