Are you gearing up for a career in Fractionation Plant Supervisor? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Fractionation Plant Supervisor and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

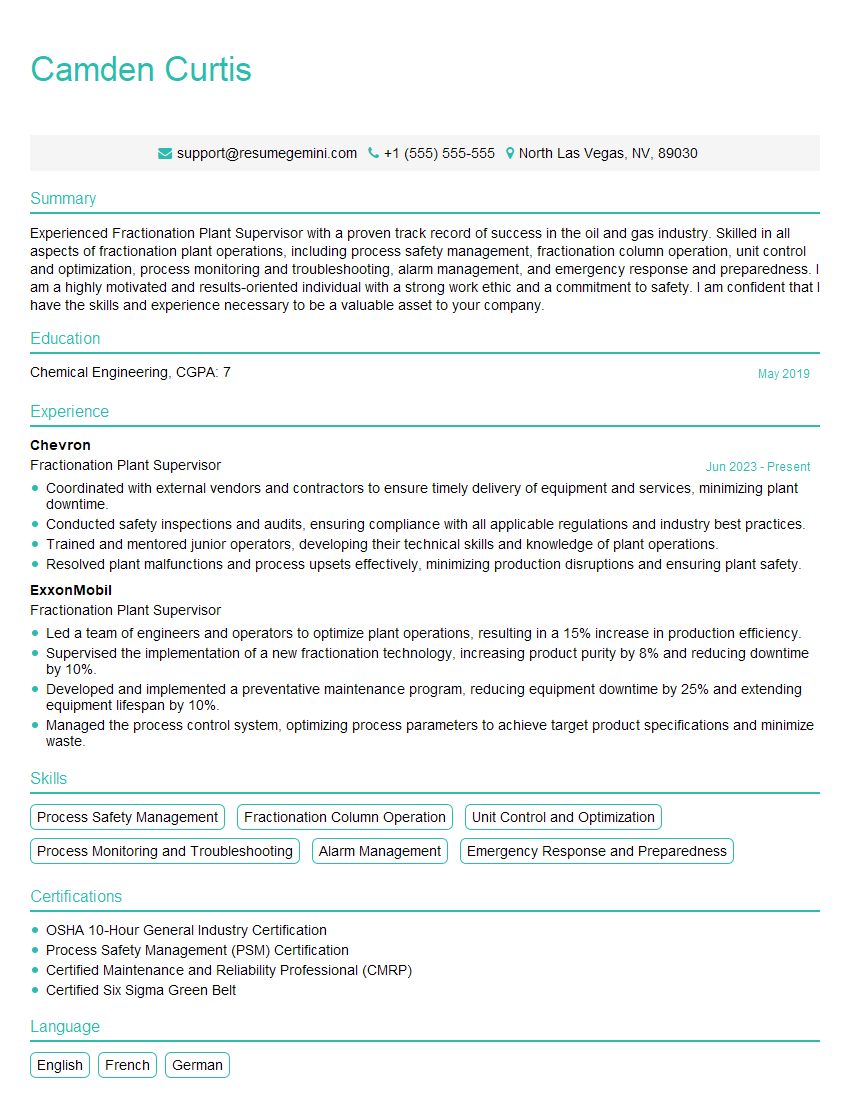

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Fractionation Plant Supervisor

1. Describe the key steps involved in the operation of a typical fractionation plant.

- Distillation of crude oil into various fractions based on their boiling points.

- Separation of gases from the crude oil using a gas separator.

- Stabilization of the fractions to remove impurities and unwanted components.

- Treatment of the fractions to meet product specifications.

- Storage and distribution of the final products.

2. What are the different types of distillation columns used in a fractionation plant?

Batch Distillation Column

- Used for small-scale production or for separating components with large differences in volatility.

- Operates by filling the column with the feed mixture and then heating it while collecting the vapor.

Continuous Distillation Column

- Used for large-scale production or for separating components with similar volatilities.

- Operates by continuously feeding the mixture into the column and withdrawing the vapor and liquid products at different points.

3. How do you optimize the operation of a distillation column to maximize product purity and yield?

- Controlling the feed rate and composition.

- Maintaining the correct temperature and pressure conditions.

- Using appropriate packing or trays to enhance separation.

- Monitoring and adjusting the reflux ratio.

- Performing regular maintenance and troubleshooting.

4. What are the common problems encountered in a fractionation plant and how do you troubleshoot them?

- Fouling: Blockage of equipment by deposits or impurities. Troubleshoot by identifying the source of the fouling and implementing cleaning or prevention measures.

- Corrosion: Damage to equipment by chemical reactions. Troubleshoot by using corrosion-resistant materials, inhibitors, or coatings.

- Equipment failure: Malfunction of pumps, valves, or other components. Troubleshoot by inspecting the equipment, identifying the fault, and repairing or replacing it.

- Process upsets: Deviations from normal operating conditions. Troubleshoot by analyzing the process data, identifying the cause, and taking corrective actions.

5. How do you ensure the safety and environmental compliance of a fractionation plant?

- Implementing and following safety protocols.

- Regularly inspecting equipment and maintaining it in good condition.

- Training staff on safety procedures.

- Monitoring environmental emissions and implementing measures to minimize pollution.

- Complying with all applicable regulations and standards.

6. Describe your experience in managing a team of operators in a fractionation plant.

- Providing clear instructions and guidance.

- Monitoring performance and providing feedback.

- Motivating and recognizing team members.

- Resolving conflicts and fostering a positive work environment.

- Ensuring compliance with safety and environmental regulations.

7. How do you stay up-to-date on the latest advancements in fractionation technology?

- Attending industry conferences and workshops.

- Reading technical journals and publications.

- Networking with other professionals in the field.

- Participating in training and development programs.

8. What are your strengths and weaknesses as a Fractionation Plant Supervisor?

-

Strengths:

- Strong technical knowledge of fractionation processes.

- Proven ability to optimize plant operations for maximum efficiency.

- Excellent communication and interpersonal skills. Weaknesses:

- Limited experience in managing large-scale fractionation plants.

- Need to develop a stronger understanding of environmental regulations.

9. Why are you interested in this Fractionation Plant Supervisor position?

- Align with my career goals and technical expertise in fractionation.

- Opportunity to contribute to a reputable organization in the industry.

- Excited about the challenges and responsibilities of supervising a fractionation plant.

- Confident in my abilities to lead a team and optimize plant operations.

10. Do you have any questions for me about the position or the company?

- Could you elaborate on the expected scope of responsibilities for this role?

- What are the company’s goals and objectives for the fractionation plant?

- Are there any specific challenges or opportunities that the plant is currently facing?

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Fractionation Plant Supervisor.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Fractionation Plant Supervisor‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Fractionation Plant Supervisor is entrusted with the responsibility of overseeing all plant operations to ensure the efficient and safe production of various chemical products. Their key job responsibilities include:

1. Production Management

The Supervisor is responsible for optimizing production performance, meeting production targets, and ensuring product quality meets specifications.

- Monitor production processes, identify bottlenecks, and implement corrective actions to improve efficiency.

- Ensure adherence to quality control standards and specifications.

2. Plant Maintenance and Safety

The Supervisor ensures the plant is well-maintained and operates safely, minimizing downtime and potential hazards.

- Plan and oversee maintenance activities, including equipment inspections, repairs, and troubleshooting.

- Implement and enforce safety protocols, conduct safety audits, and provide training to personnel.

3. Team Management

The Supervisor leads and motivates a team of plant operators, ensuring their skills and knowledge are up to date.

- Provide training, guidance, and support to plant operators.

- Foster a positive and productive work environment.

4. Process Improvement

The Supervisor continuously seeks opportunities to improve processes, reduce costs, and enhance plant performance.

- Analyze production data, identify areas for improvement, and implement corrective actions.

- Stay abreast of industry best practices and implement innovative techniques.

Interview Tips

To prepare effectively for your interview, consider the following tips:

1. Research the Company and Position

Familiarize yourself with the company’s history, values, and current projects. Research the specific responsibilities of the Fractionation Plant Supervisor and identify your relevant skills and experience that align with the requirements.

- Visit the company’s website and social media pages.

- Review industry publications and news articles.

2. Prepare for Technical Questions

Expect technical questions related to fractionation plant operations, process control, and safety. Practice answering questions about your experience in process optimization, plant maintenance, and emergency response.

- Review your knowledge of fractionation processes, equipment, and instrumentation.

- Prepare examples of your ability to troubleshoot and resolve plant issues.

3. Showcase Your Leadership Skills

Highlight your ability to lead and motivate a team. Provide examples of how you have successfully managed and developed plant operators.

- Describe your approach to employee training and performance management.

- Share examples of how you have fostered a collaborative and positive work environment.

4. Emphasize Your Problem-solving Abilities

Fractionation Plant Supervisors must be adept at problem-solving and decision-making. Prepare examples of your success in resolving plant issues, improving processes, and implementing cost-saving measures.

- Use the STAR method (Situation, Task, Action, Result) to structure your answers.

- Quantify your accomplishments whenever possible.

5. Prepare for Behavioral Questions

Interviewers may ask behavioral questions to assess your work ethic, adaptability, and communication skills.

- Review common behavioral question formats and prepare your responses.

- Use specific examples from your work experience to support your answers.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Fractionation Plant Supervisor interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!