Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Freight Elevator Erector position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

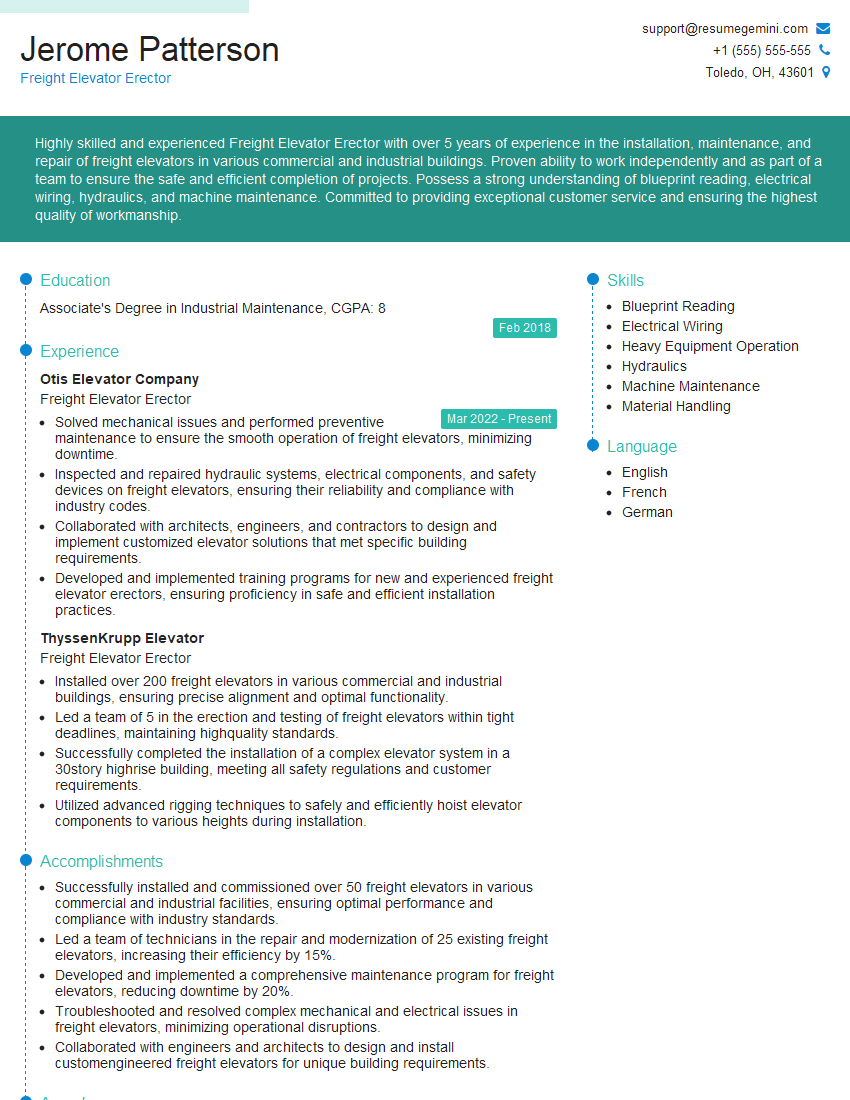

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Freight Elevator Erector

1. Explain the process of installing a freight elevator.

The process of installing a freight elevator involves several steps, here’s an overview:

- Planning and Preparation: Assessing the site, reviewing blueprints, determining equipment requirements, and obtaining necessary permits.

- Site Preparation: Preparing the site for elevator installation, including excavating for the pit and hoistway, and providing access for materials.

- Hoistway Construction: Building the hoistway, which is the vertical shaft that houses the elevator car and machinery.

- Elevator Car Assembly: Assembling and installing the elevator car, including its platform, walls, ceiling, and entrance.

- Machine Room Installation: Setting up the machine room and installing the elevator machine, controller, and other necessary equipment.

- Electrical Wiring and Connections: Installing electrical wiring throughout the system, connecting the elevator car, machine, and controls.

- Final Assembly and Testing: Completing the installation, including aligning the guides, setting up the doors, and performing comprehensive testing.

2. Describe the different types of freight elevators and their applications.

- Hydraulic Freight Elevators: Used for low-rise buildings, with a piston-driven mechanism for lifting and lowering the car.

- Traction Freight Elevators: Suitable for higher-rise buildings, with a system of ropes and pulleys powered by an electric motor.

- Machine Room-Less (MRL) Freight Elevators: Compact and space-saving, with the machine located outside the hoistway.

- Heavy-Duty Freight Elevators: Designed for handling heavy loads, with reinforced components and specialized features.

- Specialty Freight Elevators: Custom-built for unique applications, such as car elevators or scissor lifts.

3. Discuss the safety regulations and codes that apply to freight elevator installation and maintenance.

The installation and maintenance of freight elevators must adhere to various safety regulations and codes, including:

- ASME A17.1/CSA B44: Safety Code for Elevators and Escalators

- NFPA 70: National Electrical Code

- OSHA Regulations: Standards for workplace safety

- Local Building Codes: Specific requirements based on the building’s location

4. Explain the importance of proper alignment and leveling of freight elevator components.

Proper alignment and leveling of freight elevator components are crucial for ensuring smooth operation, reducing wear and tear, and extending equipment life. Misalignment can lead to issues such as vibration, noise, and premature failure.

5. Describe the tools and equipment used for freight elevator installation and maintenance.

- Levels and Measuring Devices: To ensure accurate alignment and positioning

- Hoists and Cranes: For lifting and maneuvering heavy components

- Electrical Testers: For verifying electrical connections and troubleshooting

- Hydraulic Tools: For working with hydraulic systems

- Specialized Elevator Tools: Specific tools designed for elevator maintenance

6. Explain the troubleshooting process for common freight elevator problems.

Common freight elevator problems and their troubleshooting steps may include:

- Elevator not responding: Check power supply, control panel, and electrical connections.

- Jerky or uneven movement: Inspect alignment, guide rails, and lubrication.

- Excessive noise or vibration: Check bearings, gears, and motor mounts.

- Door malfunction: Test door sensors, limit switches, and door operator.

7. Discuss the preventive maintenance procedures for freight elevators.

- Regular Inspections: Visual checks, lubrication, and functional testing

- Hoistway Inspection: Examination of hoistway components, including rails, guides, and clearances

- Electrical Maintenance: Testing and servicing electrical systems, including wiring, controls, and safety devices

- Hydraulic System Maintenance: Inspecting and servicing hydraulic components, such as cylinders, valves, and pumps

8. Explain the importance of record-keeping and documentation for freight elevator maintenance.

Record-keeping and documentation are essential for tracking maintenance activities, identifying trends, and ensuring compliance with regulations. Proper documentation includes:

- Inspection Reports: Detailing findings and recommendations from regular inspections

- Maintenance Logs: Recording all maintenance tasks performed, including dates, materials used, and any issues encountered

- Test Certificates: Verifying the operation and safety of the elevator after maintenance or repairs

9. Describe the communication and coordination required when working on freight elevator projects.

Effective communication and coordination are crucial during freight elevator projects. This involves:

- Collaboration with Engineers: Consulting with engineers for design and technical specifications

- Coordination with Contractors: Working alongside other contractors involved in the project, such as electricians and builders

- Communication with Building Management: Keeping the building management informed about project progress and maintenance requirements

10. Explain the safety precautions to be observed when working on freight elevators.

- Personal Protective Equipment (PPE): Using appropriate PPE, such as hard hats, safety glasses, and gloves

- Lockout/Tagout Procedures: Implementing lockout/tagout procedures to prevent accidental startup

- Working at Heights: Following established safety protocols for working at heights

- Electrical Safety: Observing electrical safety regulations and working with qualified electricians

- Emergency Preparedness: Knowing emergency procedures and evacuation plans

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Freight Elevator Erector.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Freight Elevator Erector‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Freight Elevator Erector is a crucial role responsible for installing, maintaining, and repairing freight elevators, ensuring their safe and efficient operation.

1. Installation

• Interpreting blueprints and specifications to determine the precise placement of elevator components.

• Assembling and erecting elevator shafts, rails, and machinery.

2. Maintenance

• Conducting regular inspections and preventive maintenance checks.

• Lubricating and adjusting moving parts to ensure smooth operation.

3. Repair

• Diagnosing and solving malfunctions promptly.

• Replacing or repairing worn or damaged components.

4. Safety Compliance

• Adhering to all applicable safety regulations and standards.

• Ensuring elevators meet building codes and manufacturer specifications.

Interview Tips

Preparing thoroughly for an interview can significantly enhance your chances of success. Here are some tips to help you ace your Freight Elevator Erector interview:

1. Research the Company and Industry

• Visit the company’s website to gather information about their history, services, and current projects.

• Explore industry news and trends to demonstrate your knowledge of the field.

2. Highlight Your Skills and Experience

• Quantify your accomplishments using specific metrics and results.

• Tailor your resume and cover letter to match the key job responsibilities.

3. Showcase Your Safety Consciousness

• Emphasize your commitment to safety regulations and adherence to industry best practices.

• Share examples of your proactive approach to hazard identification and mitigation.

4. Prepare for Technical Questions

• Review basic elevator mechanics, including cab design, motor types, and safety devices.

• Practice troubleshooting common elevator malfunctions and repair procedures.

5. Dress Professionally and Arrive on Time

• First impressions matter. Dress appropriately for an interview and arrive punctually to show respect and professionalism.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Freight Elevator Erector interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!