Feeling lost in a sea of interview questions? Landed that dream interview for Frit Mixer and Burner but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Frit Mixer and Burner interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

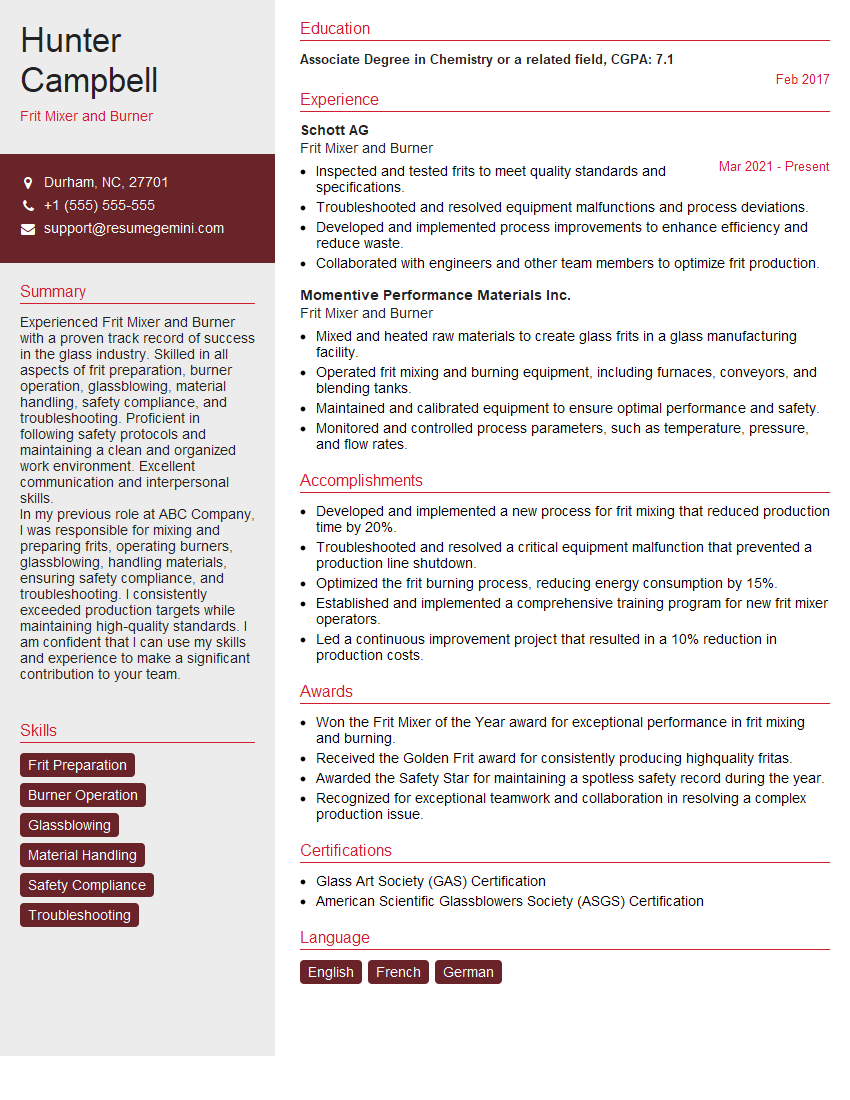

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Frit Mixer and Burner

1. What is the purpose of frit?

Frit is a mixture of glass and ceramic materials that is used to create a vitreous coating on metal surfaces. It is typically applied to steel, iron, and aluminum to protect them from corrosion and wear. Frit is also used as a decorative coating, and can be found on a variety of products, including cookware, bathroom fixtures, and architectural glass.

2. What are the different types of frit?

Lead-based frit

- Lead-based frit is the most common type of frit. It is composed of lead oxide, silica, and other glass-forming materials. Lead-based frit is durable and resistant to corrosion. However, it is not suitable for use on food-contact surfaces due to the presence of lead.

Lead-free frit

- Lead-free frit is a type of frit that does not contain lead. It is typically composed of zinc oxide, silica, and other glass-forming materials. Lead-free frit is more expensive than lead-based frit, but it is safe for use on food-contact surfaces.

Alkali-resistant frit

- Alkali-resistant frit is a type of frit that is resistant to the effects of alkaline solutions. It is typically composed of zirconia, silica, and other glass-forming materials. Alkali-resistant frit is used in applications where the frit will be exposed to alkaline conditions, such as in chemical processing equipment.

3. What are the steps involved in frit mixing and burning?

The steps involved in frit mixing and burning are as follows:

- The raw materials are weighed and mixed together in a mixer.

- The mixture is then smelted in a furnace at a temperature of 1200-1400 degrees Celsius.

- The molten frit is then poured into a mold and allowed to cool.

- The cooled frit is then ground into a powder.

- The frit powder is then mixed with water and applied to the metal surface.

- The coated metal is then fired in a kiln to fuse the frit to the metal surface.

4. What are the quality control tests that are performed on frit?

- Visual inspection: The frit is inspected for defects such as cracks, chips, and discoloration.

- Acid resistance test: The frit is tested for its resistance to acids by immersing it in a solution of hydrochloric acid.

- Alkali resistance test: The frit is tested for its resistance to alkalis by immersing it in a solution of sodium hydroxide.

- Thermal shock test: The frit is tested for its resistance to thermal shock by subjecting it to a sudden change in temperature.

5. What are the safety precautions that must be taken when working with frit?

- Frit can be harmful if inhaled or ingested. Therefore, it is important to wear a dust mask and gloves when working with frit.

- Frit can also be irritating to the skin and eyes. Therefore, it is important to wear protective clothing and eye protection when working with frit.

- Frit is a fire hazard. Therefore, it is important to keep frit away from open flames and sparks.

6. What are the applications of frit?

- Frit is used to protect metal surfaces from corrosion and wear.

- Frit is used as a decorative coating on a variety of products.

- Frit is used in the production of glass and ceramics.

7. What are the advantages of using frit?

- Frit is durable and resistant to corrosion.

- Frit is available in a variety of colors and textures.

- Frit is relatively easy to apply.

8. What are the disadvantages of using frit?

- Frit can be expensive.

- Frit can be harmful if inhaled or ingested.

- Frit can be difficult to remove from metal surfaces.

9. How can the quality of frit be improved?

- The quality of frit can be improved by using high-quality raw materials.

- The quality of frit can be improved by using a controlled smelting process.

- The quality of frit can be improved by using a proper grinding process.

10. What are the trends in the frit industry?

- There is a trend towards the use of lead-free frit due to environmental concerns.

- There is a trend towards the use of frit in new applications, such as in the production of solar cells.

- There is a trend towards the use of more automated frit mixing and burning processes.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Frit Mixer and Burner.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Frit Mixer and Burner‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Frit Mixer and Burner plays a crucial role in the production of glass and ceramic products. Their primary responsibilities include:

1. Mixing and Preparing Frit

Mixes raw materials to create frit, a glassy substance used in glass and ceramic manufacturing.

- Accurately measures and combines various ingredients according to specific formulas.

- Operates mixing equipment to blend materials thoroughly.

2. Firing and Burning Frit

Heats frit to high temperatures to convert it into a molten liquid.

- Loads frit into furnaces or kilns.

- Controls temperature and firing time to achieve desired results.

3. Monitoring and Maintaining Equipment

Ensures that mixing and firing equipment is functioning properly.

- Conducts routine inspections and maintenance checks.

- Reports any issues or malfunctions to supervisors.

4. Quality Control

Inspects and tests finished frit to ensure it meets quality standards.

- Conducts visual examinations and performs physical tests.

- Records and reports any deviations from specifications.

Interview Tips

Preparing for an interview for a Frit Mixer and Burner position requires thorough research and thoughtful preparation.

1. Research the Company and Role

Familiarize yourself with the company’s background, products, and industry. Learn about the specific responsibilities and requirements of the Frit Mixer and Burner position.

- Visit the company website and social media pages.

- Read industry publications and articles.

2. Highlight Your Technical Skills

Emphasize your knowledge and experience in mixing, firing, and testing frit. Mention any certifications or training you have received.

- Describe your ability to operate and maintain mixing and firing equipment.

- Share examples of your quality control procedures and troubleshooting skills.

3. Demonstrate Your Attention to Detail

Frit mixing and burning require meticulous attention to detail. Explain how you ensure accuracy and consistency in your work.

- Discuss your organizational skills and ability to follow instructions precisely.

- Mention any experience you have in quality control or laboratory environments.

4. Be Prepared for Behavioral Questions

Interviewers may ask behavioral questions to assess your problem-solving, teamwork, and communication skills. Prepare examples that showcase these qualities.

- Use the STAR method (Situation, Task, Action, Result) to structure your answers.

- Focus on specific accomplishments and quantify your results whenever possible.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Frit Mixer and Burner interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!