Are you gearing up for an interview for a Frothing Machine Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Frothing Machine Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

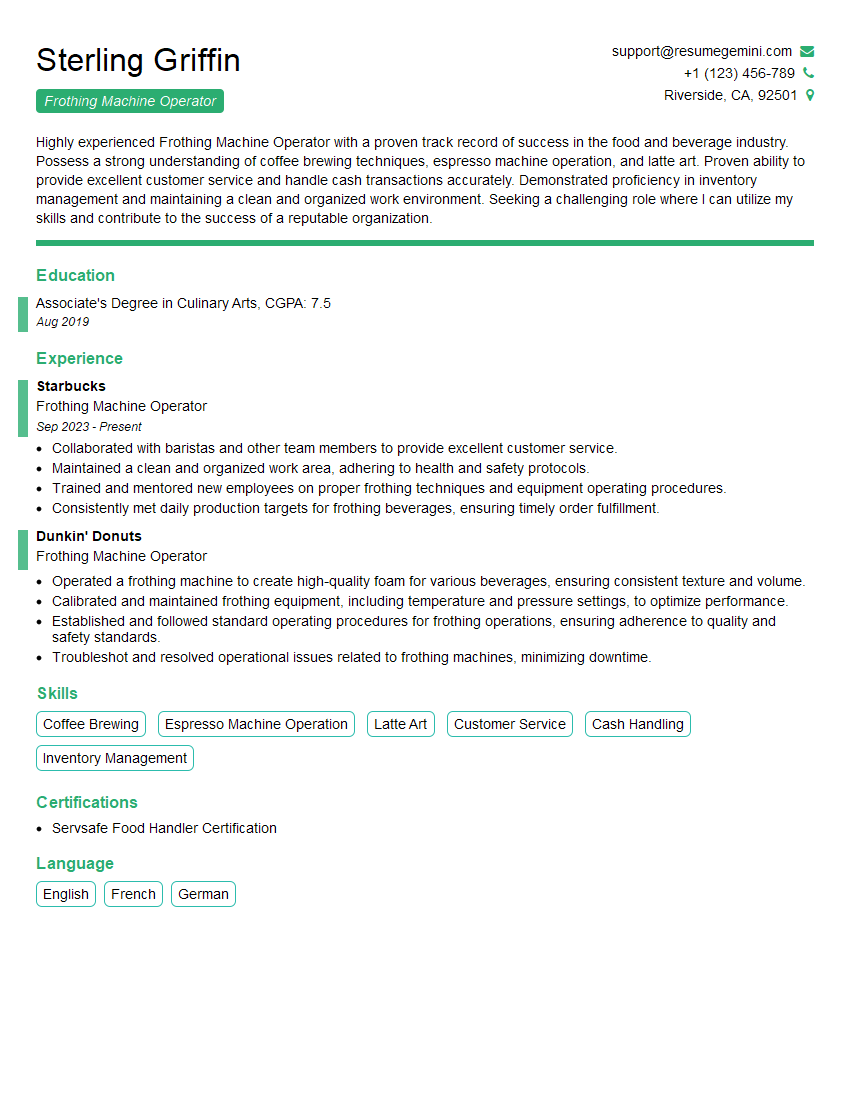

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Frothing Machine Operator

1. Describe the process of preparing a milk-based beverage on a frothing machine.

The process of preparing a milk-based beverage on a frothing machine involves the following steps:

- Filling the pitcher: Fill the pitcher with cold milk, leaving about 1/3 of the pitcher empty for frothing.

- Purging the wand: Purge the steam wand to release any excess water or milk.

- Submerging the wand: Submerge the wand just below the surface of the milk, slightly angled towards the side of the pitcher.

- Frothing the milk: Slowly open the steam valve and move the wand up and down to create a whirlpool effect, incorporating air into the milk and forming a creamy froth.

- Checking the consistency: Monitor the temperature and texture of the milk using a thermometer or by feeling the pitcher. Stop frothing when the milk reaches 150-160°F or the desired consistency.

2. Explain the difference between wet and dry frothing.

Wet frothing:

- Produces a froth with a higher water content and larger bubbles.

- Creates a lighter and airier texture.

- Ideal for drinks like cappuccinos and lattes.

Dry frothing:

- Produces a froth with a lower water content and smaller bubbles.

- Results in a thicker and creamier texture.

- Suitable for drinks like macchiatos and cortados.

3. How do you troubleshoot a frothing machine that is not producing steam?

- Check the water level: Ensure that the water reservoir is filled to the appropriate level.

- Inspect the steam wand: Examine the steam wand for any blockages or damage.

- Purge the wand: Repeat the purging process several times to clear any potential obstructions.

- Check the steam valve: Verify if the steam valve is fully open and not leaking.

- Inspect the boiler: If all else fails, the boiler may require maintenance or replacement.

4. Describe the importance of calibrating the frothing machine regularly.

- Ensures consistent performance: Regular calibration ensures that the machine delivers the correct temperature and froth quality for optimal beverage preparation.

- Optimizes efficiency: Accurate calibration contributes to efficient operation, minimizing waste and product inconsistencies.

- Prevents breakdowns: Proper calibration helps identify and resolve potential issues before they escalate into major breakdowns.

- Maintains hygiene standards: Regular calibration includes cleaning and sanitization procedures, which are crucial for maintaining hygiene and food safety.

5. Explain how you handle customer requests for various milk modifications, such as soy or almond milk.

- Understand the request: Clearly communicate with the customer to understand their specific milk preferences and any dietary restrictions.

- Check availability: Verify if the requested milk alternative is available at the time of the order.

- Adjust frothing technique: Modify the frothing technique as needed based on the characteristics of the alternative milk, such as its lower protein content.

- Ensure quality: Prepare and serve the beverage to the customer’s satisfaction, ensuring that the milk alternative is properly frothed and complements the drink.

6. How do you maintain a clean and hygienic work environment around the frothing machine?

- Regular cleaning: Wipe down the machine daily and thoroughly clean it at the end of each shift, using appropriate cleaning solutions.

- Sanitizing the wand: Purge the steam wand with a sanitizing solution after each use to eliminate bacteria.

- Cleaning the pitcher: Wash the milk pitcher with hot soapy water and rinse it thoroughly after each use.

- Routine inspection: Regularly check for any visible dirt or residue on the machine or surrounding area and address it promptly.

- Adhering to hygiene protocols: Follow established hygiene guidelines, such as wearing gloves and changing them frequently.

7. Describe your experience troubleshooting and repairing common issues with frothing machines.

I have experience troubleshooting and repairing various common issues with frothing machines, including:

- No steam production: Checking water levels, inspecting and clearing blockages in the steam wand, and examining the boiler.

- Inconsistent frothing: Calibrating the machine, adjusting the wand depth and angle, and experimenting with different milk types.

- Leaking steam: Identifying and tightening loose connections, replacing worn-out gaskets, and inspecting the steam valve.

- Electrical faults: Verifying power supply, checking fuses, and consulting with an electrician if necessary.

- Mechanical issues: Inspecting and replacing faulty parts, such as the pump or steam wand nozzle.

8. Explain how you ensure the quality and consistency of the froth when preparing beverages.

- Fresh and cold milk: Using fresh, cold milk produces better froth with a finer texture and longer shelf life.

- Appropriate milk-to-steam ratio: Maintaining an ideal ratio of milk to steam ensures balanced froth consistency and temperature.

- Optimal frothing duration: Monitoring the frothing process and stopping at the right time to prevent overheating or excessive aeration.

- Checking temperature: Using a thermometer or relying on experience to gauge the temperature of the frothed milk for optimal texture and flavor.

- Practice and consistency: Regularly practicing and refining frothing techniques to achieve consistent results.

9. Discuss the safety measures you observe when operating a frothing machine.

- Proper training: Ensuring thorough training and certification before operating the machine.

- Protective gear: Wearing appropriate safety gear, such as gloves and aprons, to protect against hot surfaces and spills.

- Careful handling of steam: Avoiding direct contact with the steam wand and using it responsibly to prevent burns.

- Machine maintenance: Regularly inspecting and maintaining the machine to prevent potential hazards.

- Emergency procedures: Being familiar with and following established emergency procedures in case of accidents or malfunctions.

10. Explain how you contribute to a positive and efficient work environment when working with other team members.

- Clear communication: Communicating effectively with colleagues to ensure smooth coordination and task completion.

- Teamwork: Collaborating and assisting team members when needed, maintaining a supportive work environment.

- Cross-training: Willingly participating in cross-training opportunities to enhance knowledge and support the team.

- Positive attitude: Maintaining a positive and enthusiastic attitude, contributing to a pleasant and productive workplace.

- Problem-solving: Working together with colleagues to identify and resolve issues, fostering a collaborative approach.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Frothing Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Frothing Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Frothing Machine Operator is responsible for operating and maintaining a frothing machine to produce foamed milk for various coffee drinks. This role requires a combination of technical skills and attention to detail to ensure the efficient and safe production of high-quality frothed milk. The key responsibilities of a Frothing Machine Operator include:

1. Machine Operation and Maintenance

– Operating the frothing machine to produce frothed milk to the required specifications

– Monitoring the machine’s performance and making necessary adjustments to ensure optimal operation

– Identifying and resolving minor operational issues and performing routine maintenance tasks

2. Product Quality Control

– Ensuring the frothed milk meets the desired consistency, texture, and temperature

– Identifying and addressing any deviations from quality standards

– Taking corrective actions to maintain product quality

3. Hygiene and Safety

– Adhering to strict hygiene and safety standards in the workplace

– Maintaining a clean and sanitized work area

– Following established safety procedures and using appropriate personal protective equipment

4. Communication and Collaboration

– Communicating effectively with other team members, including baristas and customers

– Providing assistance and support to colleagues to ensure smooth operations

– Collaborating with other departments, such as purchasing and quality control, to support the overall success of the organization

Interview Tips

Preparing for an interview for a Frothing Machine Operator position can help you showcase your skills and increase your chances of getting hired. Here are some interview tips and hacks to help you ace the interview:

1. Research the Company and Position

– Take the time to learn about the company’s culture, values, and mission

– Familiarize yourself with the specific requirements of the Frothing Machine Operator position

2. Highlight Your Experience and Skills

– Emphasize your relevant experience in operating and maintaining frothing machines

– Showcase your understanding of product quality control and hygiene standards

– Highlight your ability to work in a fast-paced environment and contribute to a team

3. Prepare for Common Interview Questions

– Practice answering common interview questions related to your experience, skills, and motivations

– Examples of possible interview questions:

- Tell us about your experience operating frothing machines.

- How do you ensure the quality and consistency of the frothed milk you produce?

- What steps do you take to maintain hygiene and safety in the workplace?

- How do you handle stressful situations in the workplace?

- Why are you interested in this position with our company?

4. Asking Questions During the Interview

– Asking thoughtful questions during the interview shows your interest in the position and the company

– Prepare questions that demonstrate your understanding of the role and your enthusiasm for the opportunity

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Frothing Machine Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.