Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Fusing Machine Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Fusing Machine Operator so you can tailor your answers to impress potential employers.

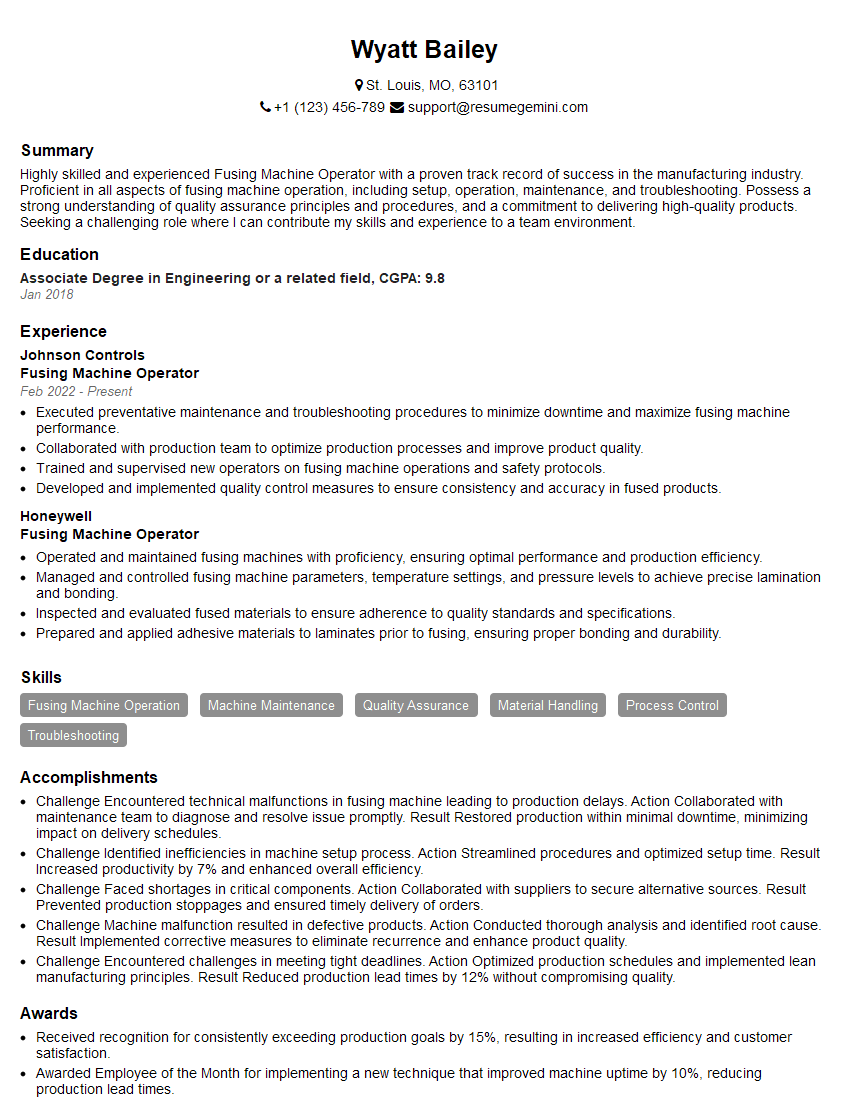

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Fusing Machine Operator

1. Explain the process of fusing two pieces of fabric using a fusing machine?

Sure, here’s a step-by-step explanation of the process of fusing two pieces of fabric using a fusing machine:

- Prepare the fabric: Start by ensuring that the fabric is clean and free of any wrinkles or creases. If necessary, iron the fabric before fusing.

- Apply the fusible interfacing: Cut a piece of fusible interfacing to the desired size and shape. Place the interfacing on the wrong side of one of the fabric pieces, ensuring that the adhesive side is facing the fabric.

- Cover with a pressing cloth: Place a pressing cloth over the fabric and interfacing to protect it from heat damage.

- Fuse the interfacing: Set the fusing machine to the appropriate temperature for the type of fabric and interfacing being used. Press down on the fabric with the machine for the recommended amount of time, applying even pressure.

- Remove the pressing cloth: Once the fusing time is complete, remove the pressing cloth and allow the fabric to cool.

- Trim the excess interfacing: Trim any excess interfacing around the edges of the fabric.

- Fuse the second fabric piece: Repeat steps 2-6 to fuse the second fabric piece to the interfaced fabric.

- Press the fused fabric: Once both fabric pieces are fused, press the fabric again with a regular iron to ensure a strong bond.

2. What are the different types of fusing machines available?

There are two main types of fusing machines available:

Flatbed fusing machines

- These machines have a flat heated surface on which the fabric is placed. The operator then presses down on the fabric with a heated platen to fuse the interfacing.

- Flatbed fusing machines are ideal for fusing large pieces of fabric or for fusing interfacing to delicate fabrics.

Rotary fusing machines

- These machines have a heated roller that rotates as the fabric is fed through it. The heat from the roller fuses the interfacing to the fabric.

- Rotary fusing machines are ideal for high-volume fusing applications.

3. What factors should be considered when selecting a fusing machine?

When selecting a fusing machine, several factors should be considered:

- The type of fabric being fused: Different fabrics require different fusing temperatures and times. It is important to choose a machine that can accommodate the types of fabrics that will be fused.

- The size of the fusing area: The size of the fusing area will determine the size of the fabric pieces that can be fused. Choose a machine with a fusing area that is large enough for your needs.

- The speed of the fusing machine: The speed of the fusing machine will determine how quickly you can fuse fabric. Choose a machine with a speed that meets your production requirements.

- The cost of the fusing machine: Fusing machines can range in price from a few hundred dollars to several thousand dollars. Choose a machine that fits your budget.

4. What are the most common problems that can occur when using a fusing machine?

The most common problems that can occur when using a fusing machine include:

- Fabric scorching: This can occur if the fusing temperature is too high or if the fabric is left on the fusing surface for too long.

- Fabric puckering: This can occur if the fabric is not properly stretched before fusing or if the fusing pressure is too high.

- Interfacing bubbling: This can occur if the interfacing is not properly applied to the fabric or if the fusing temperature is too low.

- Machine malfunction: Fusing machines can malfunction for various reasons, such as electrical problems or mechanical failure.

5. How can these problems be prevented?

These problems can be prevented by taking the following precautions:

- Use the correct fusing temperature and time for the type of fabric being fused.

- Stretch the fabric properly before fusing.

- Apply the interfacing properly to the fabric.

- Maintain the fusing machine regularly.

6. What are the safety precautions that should be taken when using a fusing machine?

When using a fusing machine, it is important to take the following safety precautions:

- Wear appropriate safety gear, such as gloves and safety glasses.

- Keep the fusing area clean and free of clutter.

- Do not touch the heated surfaces of the machine.

- Unplug the machine when not in use.

7. How do you maintain a fusing machine?

To maintain a fusing machine, it is important to:

- Clean the fusing surface regularly.

- Lubricate the moving parts of the machine.

- Inspect the machine regularly for any signs of damage.

- Calibrate the machine regularly.

8. What are the different types of fusible interfacing available?

There are several different types of fusible interfacing available, including:

- Woven interfacing: This type of interfacing is made from woven fibers and is available in a variety of weights and stiffnesses.

- Non-woven interfacing: This type of interfacing is made from non-woven fibers and is available in a variety of weights and stiffnesses.

- Knit interfacing: This type of interfacing is made from knitted fibers and is available in a variety of weights and stiffnesses.

- Thermoplastic interfacing: This type of interfacing is made from thermoplastic fibers and is available in a variety of weights and stiffnesses.

9. How do you choose the right type of fusible interfacing for a particular project?

The type of fusible interfacing that you choose will depend on the following factors:

- The type of fabric being used.

- The desired stiffness of the interfaced fabric.

- The application of the interfaced fabric.

10. What are some tips for using fusible interfacing?

Here are some tips for using fusible interfacing:

- Always test the interfacing on a scrap piece of fabric before using it on your project.

- Use the correct fusing temperature and time for the type of fabric and interfacing being used.

- Apply the interfacing evenly to the fabric.

- Press the interfaced fabric thoroughly to ensure a strong bond.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Fusing Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Fusing Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Fusing Machine Operators play a vital role in the production, packaging, and manufacturing sectors. They are responsible for operating and monitoring fusing machines, which bond materials together using heat and pressure. This role requires technical skills, attention to detail, and the ability to work in a fast-paced environment.

1. Machine Operation

The primary task of a Fusing Machine Operator is to operate and monitor fusing machines. This involves:

- Setting up the machine according to production specifications

- Loading and feeding materials into the machine

- Adjusting machine parameters, such as temperature and pressure

- Monitoring the fusing process to ensure quality and efficiency

2. Quality Control

Fusing Machine Operators are responsible for maintaining product quality by:

- Inspecting materials before and after fusing

- Identifying and correcting defects

- Maintaining records of production and quality control

3. Machine Maintenance

To ensure optimal performance and longevity of the fusing machine, Fusing Machine Operators are responsible for:

- Performing routine maintenance and cleaning

- Identifying and reporting any mechanical issues

- Coordinating with maintenance personnel for repairs

4. Safety

Fusing Machine Operators must adhere to safety regulations by:

- Wearing appropriate personal protective equipment

- Following established safety procedures

- Maintaining a clean and organized work area

Interview Tips

Preparing thoroughly for an interview can significantly increase your chances of success. Here are some valuable tips to help you ace your interview for a Fusing Machine Operator position:

1. Research the Company

Take the time to research the company you are applying to. Familiarize yourself with their products or services, industry presence, and company culture. This knowledge will help you tailor your answers to the interviewer’s questions and demonstrate your genuine interest in the position.

2. Practice Your Answers

Anticipate common interview questions and prepare your answers in advance. Consider using the STAR method (Situation, Task, Action, Result) to structure your responses effectively. This method allows you to provide specific examples of your skills and experiences.

3. Showcase Your Technical Skills

Highlight your technical abilities and experience in operating fusing machines. Explain your understanding of the fusing process, machine parameters, and quality control procedures. Provide examples of how you have used your technical skills to solve problems or improve efficiency.

4. Emphasize Safety and Quality

In any manufacturing setting, safety and quality are paramount. Emphasize your commitment to maintaining a safe work environment and adhering to established safety regulations. Additionally, highlight your attention to detail and your ability to consistently produce high-quality products.

5. Ask Insightful Questions

Prepare thoughtful questions to ask the interviewer. This shows that you are engaged, interested in the position, and eager to learn more about the company. Your questions should be specific and related to the role or the industry.

6. Demonstrate Your Teamwork Skills

Many manufacturing environments require teamwork and collaboration. Highlight your ability to work effectively with others, communicate clearly, and contribute to a positive team atmosphere. Provide examples of how you have successfully collaborated with colleagues to achieve common goals.

7. Dress Professionally

First impressions matter. Dress professionally and appropriately for the interview. Wear clean, pressed clothing that reflects the company’s culture and the formality of the position.

8. Arrive on Time

Punctuality is essential. Arrive for your interview on time to demonstrate your respect for the interviewer and the company’s time. Punctuality also reflects your organizational skills and reliability.

Next Step:

Now that you’re armed with the knowledge of Fusing Machine Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Fusing Machine Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini