Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Garnett Room Worker position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

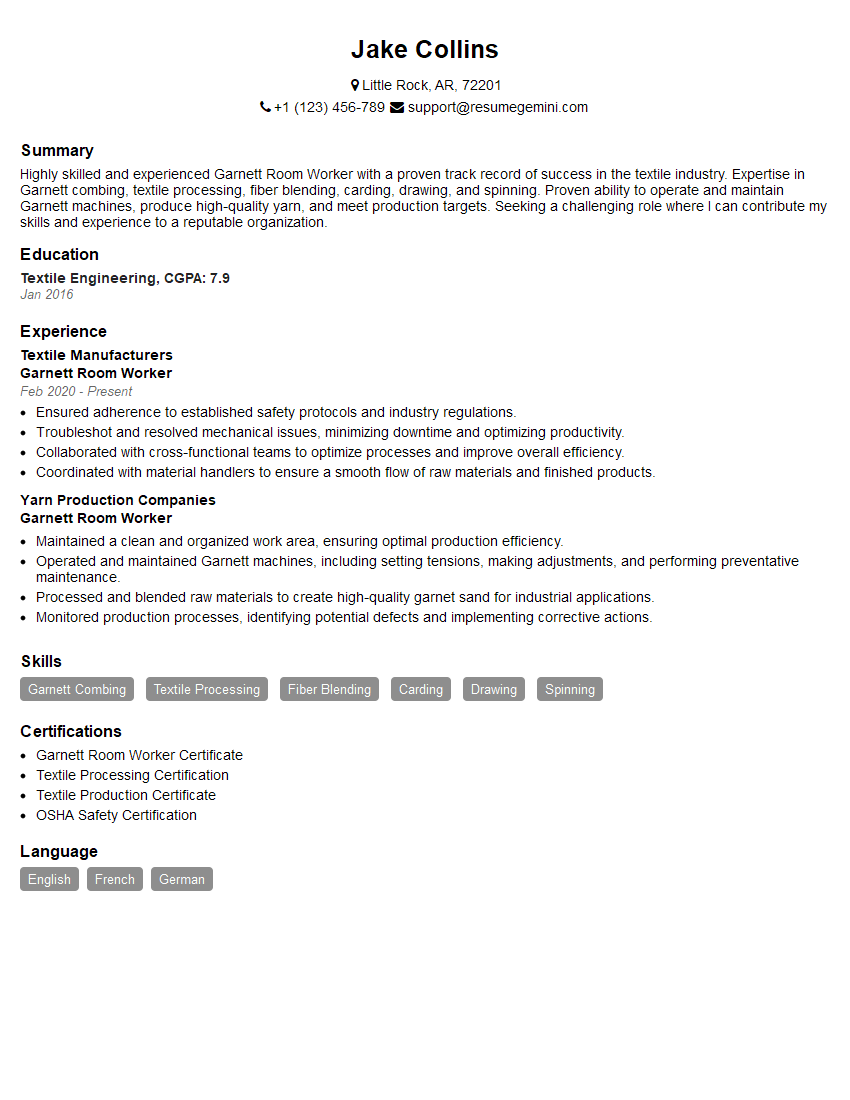

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Garnett Room Worker

1. Can you describe the process for setting up and calibrating a Garnett machine?

Setting up and calibrating a Garnett machine involves the following steps:

- Align the machine: Align the cylinder with the condenser and doffer, ensuring proper meshing and alignment.

- Set the card feed: Adjust the feed rollers to maintain the desired fiber density and evenness.

- Establish drafting settings: Determine and set the drafting roller distances and speeds to achieve the desired fiber alignment and sliver quality.

- Calibrate the cutting cycle: Set the cutting speed and depth to separate the fibers into the desired length and consistency.

- Monitor and adjust: Regularly monitor the machine’s performance, adjust settings as needed, and make sure the fiber is being processed correctly.

2. What are the key maintenance tasks required for a Garnett machine?

Regular Maintenance:

- Clean and inspect the machine daily, removing fiber buildup and debris.

- Lubricate moving parts as per the manufacturer’s recommendations.

- Check and adjust belts for tension and alignment.

- Monitor the condition of the cylinder teeth and replace them if worn.

Periodic Maintenance:

- Inspect and clean the condenser and doffer for any fiber buildup.

- Check and replace bearings if necessary.

- Calibrate the cutting cycle and optimize machine settings for efficiency.

3. Can you explain the different types of fibers that can be processed in a Garnett machine?

A Garnett machine can process a wide range of natural and synthetic fibers, including:

- Natural fibers: Cotton, wool, linen, jute, sisal

- Synthetic fibers: Polyester, nylon, acrylic, polypropylene

- Blends: Combinations of natural and synthetic fibers

4. What are the safety precautions that must be followed when operating a Garnett machine?

Operating a Garnett machine safely requires adherence to the following precautions:

- Wear appropriate safety gear, including gloves and safety glasses.

- Keep long hair and loose clothing away from moving parts.

- Never attempt to clear jams or adjust the machine while it is running.

- Lock out and tag out the machine before performing any maintenance or repairs.

- Follow established safety protocols and guidelines set by the manufacturer and workplace.

5. What are the common challenges faced when operating a Garnett machine?

- Fiber tangling and breakage: Ensuring proper fiber feed and drafting settings is crucial to prevent tangling and fiber damage.

- Uneven sliver quality: Calibrating and maintaining the machine’s settings is essential for producing consistent sliver quality.

- Machine wear and maintenance: Regular maintenance and timely replacement of worn parts are necessary to maintain optimal performance and prevent breakdowns.

- Dust and fiber buildup: Managing dust and fiber buildup in the machine is important for safe operation and consistent fiber processing.

6. Can you describe your experience in troubleshooting and resolving Garnett machine issues?

During my previous role as a Garnett Room Worker, I encountered and resolved various machine issues, including:

- Uneven sliver production: I adjusted the drafting settings and cylinder speed to optimize fiber alignment and sliver consistency.

- Fiber tangling: I identified and cleared fiber buildup in the condenser and doffer, ensuring smooth fiber flow.

- Machine vibration: I inspected and tightened loose bolts and bearings, eliminating vibration and ensuring stable operation.

7. What are your strengths and weaknesses as a Garnett Room Worker?

Strengths:

- Thorough understanding of Garnett machine setup, calibration, and maintenance.

- Ability to troubleshoot and resolve machine issues efficiently.

- Strong attention to detail and commitment to producing high-quality slivers.

Weaknesses:

- Limited experience in working with certain specialty fibers (e.g., cashmere).

- Working under pressure in fast-paced environments may occasionally impact my productivity.

8. How do you stay updated on the latest advancements in Garnett machine technology?

I stay updated on the latest advancements in Garnett machine technology through the following:

- Attending industry conferences and workshops.

- Reading trade publications and technical journals.

- Consulting with manufacturers and industry experts.

- Participating in online forums and discussion groups.

9. What motivates you to perform your best as a Garnett Room Worker?

My motivation as a Garnett Room Worker stems from:

- Quality workmanship: I take pride in producing high-quality slivers that contribute to the overall quality of the final product.

- Problem-solving challenges: Troubleshooting and resolving Garnett machine issues presents a rewarding challenge that keeps me engaged.

- Contribution to team success: As a Garnett Room Worker, I am part of a team that works together to achieve production targets and maintain a safe and efficient work environment.

10. Why are you interested in working as a Garnett Room Worker for our company?

I am eager to join your company as a Garnett Room Worker for the following reasons:

- Reputation for excellence: Your company’s reputation for producing high-quality textile products aligns with my commitment to delivering superior results.

- Advanced technology: I am impressed by your company’s investment in cutting-edge Garnett machine technology, which provides opportunities for professional growth and development.

- Team-oriented environment: I believe that my skills and experience would complement your team, contributing to the overall success of your Garnett Room operations.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Garnett Room Worker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Garnett Room Worker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Garnett Room Worker is responsible for a variety of duties in the yarn manufacturing process, including:

1. Preparing and Blending Raw Materials

Ensuring the smooth operation of the Garnett machine by preparing and blending raw materials such as wool, acrylic, and other fibers.

- Loading the machine with raw materials according to specified proportions.

- Monitoring the blending process to ensure proper mixing and consistency.

2. Operating the Garnett Machine

Operating the Garnett machine to separate, clean, and card the fibers, creating a uniform blend.

- Setting up the machine according to production requirements.

- Monitoring the machine’s performance and making necessary adjustments to maintain optimal operation.

3. Inspecting and Maintaining Finished Product

Inspecting the finished product to ensure it meets quality standards.

- Identifying and removing any imperfections or contaminants.

- Conducting regular maintenance on the Garnett machine to ensure its proper functioning.

4. Maintaining a Clean and Safe Work Environment

Maintaining a clean and safe work environment by following established safety procedures.

- Keeping the work area free of debris and hazards.

- Wearing appropriate safety gear and following safety protocols.

Interview Tips

To ace the interview for a Garnett Room Worker position, it is essential to prepare thoroughly and demonstrate your understanding of the role’s responsibilities. Here are some tips to help you succeed:

1. Research the Company and Position

Research the company’s background, mission, and products to gain insights into their business operations. Understand the specific requirements of the Garnett Room Worker position, including the machinery and processes involved.

- Visit the company’s website and social media pages.

- Read industry publications and articles to stay updated on the latest trends and best practices.

2. Highlight Relevant Skills and Experience

In your resume and during the interview, emphasize your skills and experience that are relevant to the Garnett Room Worker role. Quantify your accomplishments whenever possible to demonstrate your impact.

- Describe your experience operating and maintaining yarn manufacturing machinery.

- Showcase your understanding of fiber blending and carding processes.

3. Demonstrate Attention to Detail and Quality

Garnett Room Workers must have a keen eye for detail and a commitment to producing high-quality yarns. Highlight your strengths in these areas throughout the interview.

- Provide examples of how you have maintained high standards of quality in previous roles.

- Explain your understanding of the importance of precision and accuracy in yarn manufacturing.

4. Prepare for Common Interview Questions

Practice answering common interview questions related to the Garnett Room Worker role. This will help you articulate your qualifications and demonstrate your enthusiasm for the position.

- Explain your experience with Garnett machines and other yarn manufacturing equipment.

- Describe your understanding of the Garnett machine’s operation and maintenance procedures.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Garnett Room Worker interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!