Are you gearing up for an interview for a Garnetter position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Garnetter and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

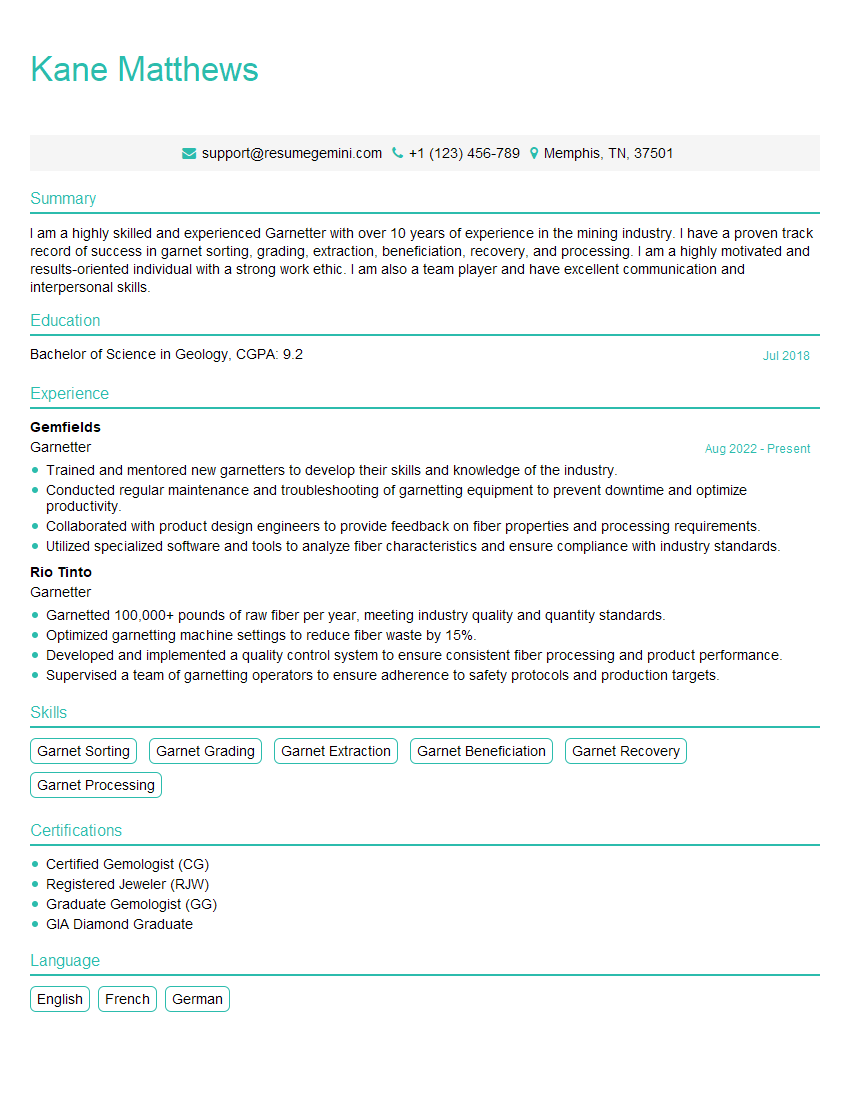

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Garnetter

1. Explain the concept of diamond grit sizes and how they affect the cutting performance of a garnetter?

Diamond grit sizes refer to the size of the individual diamond particles used in the garnetter’s abrasive surface. The size of these particles directly affects the cutting performance of the garnetter in the following ways:

- Larger grits, such as 30/40 or 40/50, are used for aggressive cutting and stock removal. They are typically used in the initial stages of grinding or shaping a workpiece.

- Smaller grits, such as 60/80 or 80/100, are used for finer finishing and polishing. They produce a smoother surface and are used in the later stages of grinding or for precision finishing.

- The choice of grit size depends on the desired surface finish, the hardness of the workpiece material, and the desired cutting speed. Larger grits cut faster but produce a rougher surface, while smaller grits cut slower but produce a finer surface finish.

2. Describe the different types of bonding systems used in garnetters and their advantages and disadvantages.

Metallic Bonding

- Advantages: High strength, long life, suitable for heavy-duty applications.

- Disadvantages: Can be brittle, not suitable for precision work.

Resin Bonding

- Advantages: Good precision, low heat generation, suitable for fine finishing.

- Disadvantages: Lower strength and durability compared to metallic bonding.

Vitrified Bonding

- Advantages: Very high strength, suitable for high-speed grinding.

- Disadvantages: More expensive, can be brittle.

3. What factors should be considered when selecting a garnetter for a particular grinding application?

When selecting a garnetter for a particular grinding application, the following factors should be considered:

- Type of workpiece material: The hardness and abrasiveness of the workpiece material will influence the choice of diamond grit size and bonding system.

- Desired surface finish: The required surface finish will determine the appropriate grit size and bonding system.

- Grinding conditions: The speed, feed rate, and coolant used during grinding will affect the performance of the garnetter.

- Machine capabilities: The size and power of the grinding machine will limit the size and type of garnetter that can be used.

4. Explain the safety precautions that should be taken when operating a garnetter.

When operating a garnetter, the following safety precautions should be taken:

- Wear appropriate safety gear: This includes safety glasses, ear protection, gloves, and a dust mask.

- Inspect the garnetter before use: Check for any cracks or damage that could cause failure.

- Operate the garnetter at the recommended speed: Exceeding the recommended speed can cause the garnetter to shatter.

- Use the proper coolant: The correct coolant will help to prevent overheating and extend the life of the garnetter.

- Never force the garnetter: If the garnetter is not cutting properly, do not force it. Stop the machine and check for any problems.

5. Describe the process of dressing a garnetter and why it is important.

Dressing a garnetter is the process of reconditioning the abrasive surface to restore its cutting performance. This is done by removing the worn diamond particles and exposing new, sharp particles. The dressing process is important for the following reasons:

- Improved cutting performance: A sharp garnetter cuts faster and produces a better surface finish.

- Increased tool life: A well-dressed garnetter will last longer before it needs to be replaced.

- Prevention of glazing: Glazing is a condition where the diamond particles become coated with workpiece material, which reduces the cutting efficiency. Dressing removes this material and prevents glazing.

6. What are the common causes of garnetter failure and how can they be prevented?

The common causes of garnetter failure include:

- Overheating: This can be caused by using an incorrect coolant or running the garnetter at too high a speed.

- Mechanical damage: This can be caused by dropping the garnetter or hitting it against a hard object.

- Wear: The diamond particles will eventually wear down and need to be replaced.

These failures can be prevented by the following measures:

- Using the correct coolant: The correct coolant will help to prevent overheating and extend the life of the garnetter.

- Running the garnetter at the recommended speed: Exceeding the recommended speed can cause the garnetter to shatter.

- Storing the garnetter properly: When not in use, the garnetter should be stored in a dry place to prevent rust.

7. Describe the different types of garnetters available and their applications.

The different types of garnetters available include:

- Cylindrical garnetters: These are used for general-purpose grinding and shaping.

- Cup garnetters: These are used for grinding and shaping concave surfaces.

- Segment garnetters: These are used for grinding and shaping large, flat surfaces.

- Profile garnetters: These are used for grinding and shaping complex profiles.

The choice of garnetter type will depend on the specific grinding application.

8. What are the latest advancements in garnetter technology?

Some of the latest advancements in garnetter technology include:

- New diamond grit materials: These materials are harder and more durable than traditional diamond grits, resulting in longer tool life and better cutting performance.

- Improved bonding systems: These systems provide better support for the diamond grits, resulting in increased strength and durability.

- New manufacturing techniques: These techniques allow for more precise and consistent manufacturing of garnetters, resulting in improved performance and reliability.

9. How do you stay up to date on the latest garnetter technology and best practices?

I stay up to date on the latest garnetter technology and best practices by the following means:

- Attending industry conferences and trade shows: These events provide a great opportunity to learn about new products and technologies from the leading manufacturers.

- Reading industry publications: There are a number of excellent industry publications that cover the latest developments in garnetter technology.

- Networking with other garnetter users: I am actively involved in several online and offline communities where I can share knowledge and experiences with other garnetter users.

10. What are your career goals and how does this position align with them?

My career goal is to become a leading expert in the field of garnetter technology. I am passionate about this technology and I believe that I have the skills and experience to make a significant contribution to the industry. This position is an excellent opportunity for me to learn from some of the best in the business and to develop my skills and knowledge. I am confident that I can make a valuable contribution to your company and help you to achieve your goals.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Garnetter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Garnetter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Garnetter is responsible for a wide range of tasks related to the preparation and processing of gemstones. Here are some of the key job responsibilities:

1. Selecting and Preparing Raw Gemstones

Garnetters start by selecting and preparing raw gemstones. This involves identifying gemstones that are suitable for cutting and polishing, as well as removing impurities and other unwanted materials.

- Inspecting raw gemstones for quality and suitability

- Removing impurities, flaws, and other imperfections

- Cutting and shaping gemstones into desired forms

2. Cutting and Polishing Gemstones

Once the gemstones have been prepared, Garnetters then cut and polish them. This requires using specialized equipment and techniques to create a beautiful, finished product.

- Using a diamond saw to cut gemstones into specific shapes

- Polishing gemstones using a variety of abrasive materials

- Creating facets on gemstones to enhance their brilliance

3. Inspecting and Grading Gemstones

After the gemstones have been cut and polished, Garnetters inspect and grade them. This involves evaluating the quality of the gemstones based on various factors, such as clarity, color, and cut.

- Examining gemstones under magnification to identify any imperfections

- Assessing the clarity, color, and cut of gemstones

- Determining the grade of gemstones based on established standards

4. Packaging and Shipping Gemstones

Once the gemstones have been graded, Garnetters package and ship them to customers. This involves ensuring that the gemstones are protected during transport and that they arrive at their destination in perfect condition.

- Packaging gemstones in protective materials

- Preparing shipping documents and labels

- Coordinating with shipping companies to ensure timely delivery

Interview Tips

Preparing for a Garnetter interview can be daunting, but by following these tips and tricks, you can increase your chances of success:

1. Research the Company and the Position

Before the interview, take the time to research the company and the specific position you are applying for. This will help you understand the company’s culture, values, and goals, as well as the specific responsibilities of the Garnetter position.

2. Practice Your Answers to Common Interview Questions

There are a number of common interview questions that you are likely to be asked, such as “Why are you interested in this position?” and “What are your strengths and weaknesses?” Practice your answers to these questions in advance so that you can deliver them confidently and concisely.

3. Prepare Questions to Ask the Interviewer

Asking thoughtful questions at the end of the interview shows that you are interested in the position and that you have done your research. Prepare a few questions in advance that will help you learn more about the company, the position, and the interviewer.

4. Dress Professionally and Arrive on Time

First impressions matter, so dress professionally for your interview and arrive on time. This shows that you respect the interviewer’s time and that you are serious about the position.

5. Be Yourself and Be Enthusiastic

The most important thing is to be yourself and be enthusiastic about the position. Let the interviewer see your passion for gemstones and your desire to learn more about the industry.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Garnetter interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!