Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Gas Burner Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

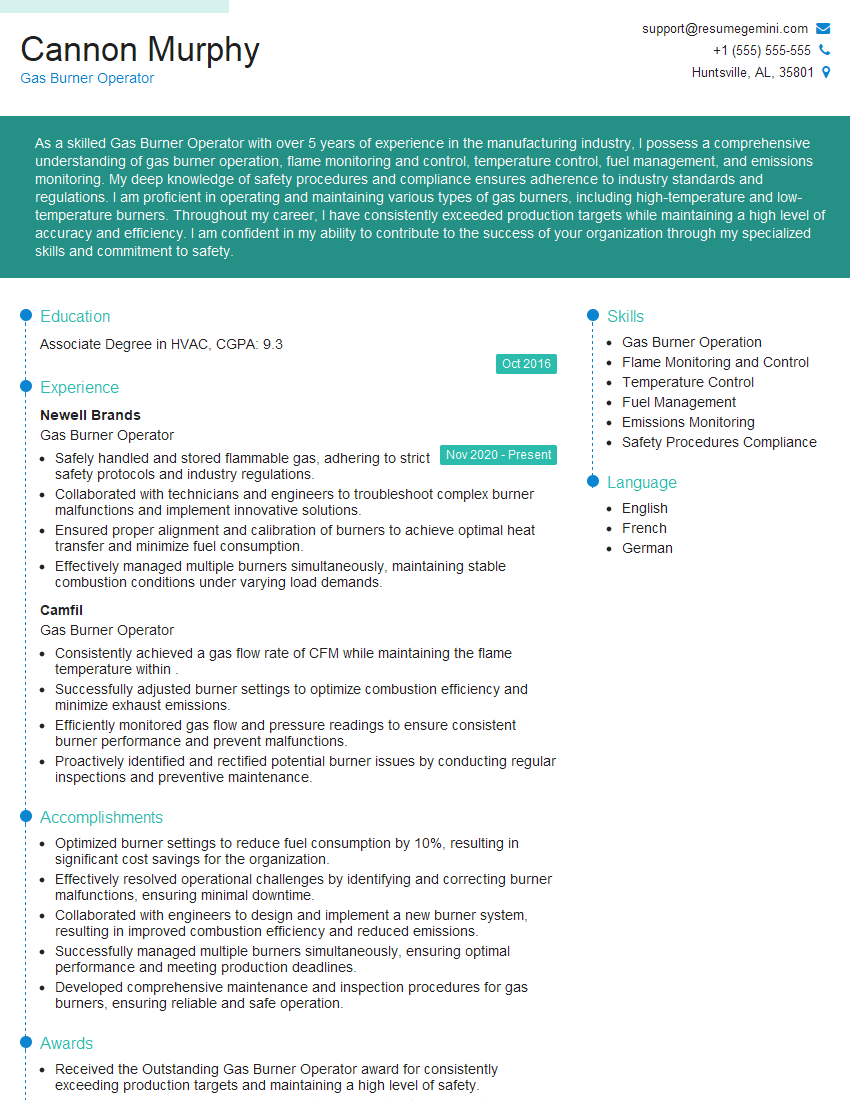

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Gas Burner Operator

1. Explain the process of operating a gas burner system?

The operation of a gas burner system involves several key steps:

- Pre-ignition checks: Ensuring the system is ready for ignition by verifying gas supply, fuel pressure, and proper ventilation.

- Ignition: Initiating the ignition process using a spark or flame to ignite the gas.

- Combustion: Monitoring the combustion process to ensure proper flame characteristics, temperature, and efficiency.

- Gas flow regulation: Adjusting gas flow rates to maintain desired flame conditions and heat output.

- Temperature control: Utilizing sensors and control systems to maintain the desired temperature within the system.

- Safety monitoring: Continuously monitoring the system for any potential hazards or malfunctions, such as flame failure, loss of fuel pressure, or excessive temperatures.

- Shutdown: Safely shutting down the system when necessary, following proper procedures to prevent any hazards.

2. What are the key safety precautions to observe when working with gas burners?

Personal Safety:

- Wear appropriate personal protective equipment (PPE) including flame-resistant clothing, gloves, and safety glasses.

- Be aware of the location of emergency shutoff valves and fire extinguishers.

- Avoid working alone near gas burners.

System Safety:

- Ensure proper ventilation to prevent gas buildup.

- Regularly inspect gas lines and connections for leaks.

- Test safety devices, such as flame detectors and temperature sensors, to ensure proper functioning.

- Follow all manufacturer’s instructions and safety protocols.

3. How do you troubleshoot common problems encountered with gas burners?

- Flame failure: Check for proper ignition, gas supply, and airflow; clean burner nozzle if necessary.

- Low flame intensity: Check for clogged burner ports, obstructed gas flow, or incorrect gas pressure.

- Excessive flame temperature: Adjust gas flow rate, check for proper combustion air supply, and inspect burner for any damage.

- Gas leaks: Use a gas detector to locate leaks; tighten connections or replace faulty components.

- Temperature control issues: Calibrate temperature sensors, adjust control settings, or inspect for any faulty components in the temperature regulation system.

4. Describe the different types of gas burners and their applications?

- Atmospheric burners: Use ambient air for combustion; commonly used in residential furnaces and water heaters.

- Premix burners: Mix gas and air before combustion; provide higher efficiency and lower emissions; used in industrial processes.

- Radiant burners: Emit heat through infrared radiation; used in grills and food processing.

- Diffusion burners: Allow gas and air to mix gradually during combustion; used in boilers and kilns.

- Burners with special features: Can include modulating burners (adjust flame intensity), staged burners (multiple stages for efficient combustion), and low-NOx burners (reduce nitrogen oxide emissions).

5. Explain the importance of proper burner maintenance?

- Safety: Regular maintenance ensures the safe operation of gas burners by preventing leaks, malfunctions, and potential hazards.

- Efficiency: Clean and well-maintained burners operate at optimal efficiency, saving energy costs and reducing emissions.

- Reliability: Scheduled maintenance helps identify potential problems early on, preventing unexpected breakdowns and ensuring reliable operation.

- Compliance: Proper burner maintenance is often required by codes and regulations to ensure safety and environmental standards are met.

6. What are the key components of a gas burner system and their functions?

- Burner: Mixes gas and air to produce a flame.

- Fuel supply: Provides gas to the burner.

- Air supply: Provides air for combustion.

- Ignition system: Initiates the combustion process.

- Temperature control system: Regulates the temperature of the burner.

- Safety devices: Monitor the system for potential hazards and shut it down if necessary.

7. Discuss the environmental impact of gas burner emissions and how to mitigate them?

- Carbon dioxide (CO2): A greenhouse gas emitted during combustion; can be reduced by using energy-efficient burners and renewable fuels.

- Nitrogen oxides (NOx): Contribute to smog and acid rain; can be reduced by using low-NOx burners and catalytic converters.

- Particulate matter: Small particles emitted during combustion; can be reduced by using filters and electrostatic precipitators.

- Mitigation strategies: Use clean-burning fuels, optimize combustion processes, implement emission control technologies, and monitor emissions regularly.

8. Describe your experience with different types of industrial burners?

I have worked with a variety of industrial burners, including:

- Atmospheric burners: Used in furnaces and kilns.

- Premix burners: Used in boilers and gas turbines.

- Radiant burners: Used in food processing and drying.

- Diffusion burners: Used in boilers and kilns.

- Burners with special features: Such as modulating burners, staged burners, and low-NOx burners.

9. Explain how you would approach optimizing the combustion process in a gas burner system?

- Analyze the existing system: Evaluate the current combustion efficiency, fuel consumption, and emission levels.

- Identify areas for improvement: Determine potential areas where combustion can be optimized, such as burner design, fuel-air ratio, and temperature control.

- Implement optimization measures: Make necessary adjustments to the burner, fuel supply, or control system to improve combustion efficiency and reduce emissions.

- Monitor and evaluate results: Track the changes and monitor the impact on combustion efficiency, fuel consumption, and emissions to ensure the optimization is effective.

10. Discuss the importance of proper gas burner calibration and how it affects system performance?

- Accuracy: Proper calibration ensures accurate gas flow rates and fuel-air ratios, resulting in optimal combustion efficiency.

- Efficiency: Incorrect calibration can lead to excessive fuel consumption and reduced system efficiency.

- Emissions: Uncalibrated burners can produce higher levels of pollutants, such as NOx and CO.

- Safety: Properly calibrated burners operate within safe limits, minimizing the risk of explosions or other hazards.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Gas Burner Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Gas Burner Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Gas Burner Operators are responsible for operating and maintaining industrial gas burners used in various manufacturing processes. They ensure that the burners operate efficiently, safely, and meet production requirements.

1. Burner Operation

Monitor and control gas burner settings to maintain optimal combustion

- Adjust gas flow rate and air-to-fuel ratio

- Monitor flame characteristics and adjust burners accordingly

2. Maintenance and Troubleshooting

Perform regular maintenance and troubleshooting of gas burners and associated equipment

- Inspect and clean burners, nozzles, and pipelines

- Identify and repair burner malfunctions

3. Safety and Regulations

Ensure compliance with safety regulations and operating procedures

- Follow proper gas handling and storage protocols

- Conduct regular safety checks and inspections

4. Communication and Recordkeeping

Communicate effectively with supervisors, engineers, and other team members

- Maintain accurate records of burner operations and maintenance

- Report any anomalies or concerns

Interview Tips

Preparing thoroughly for a job interview is crucial for success. Here are some useful tips for candidates applying for a Gas Burner Operator position:

1. Research the Company and Role

Gather information about the company’s industry, products or services, and the specific responsibilities of the Gas Burner Operator role.

- Visit the company website and social media pages

- Read industry news and articles related to gas burner technology

2. Highlight Relevant Skills and Experience

Emphasize your technical abilities in gas burner operation and maintenance. Quantify your accomplishments with specific examples and metrics.

- Describe instances where you successfully diagnosed and resolved burner malfunctions

- Mention any certifications or training related to gas burner safety and regulations

3. Demonstrate Safety Consciousness

Gas Burner Operators handle flammable materials, so safety is paramount. Showcase your understanding of safety procedures and your commitment to adhering to them.

- Provide examples of how you have followed proper gas handling and storage protocols

- Explain your experience in conducting safety inspections and risk assessments

4. Prepare for Technical Questions

Expect technical questions related to gas burner operation and maintenance. Be prepared to discuss topics such as:

- Combustion principles and flame characteristics

- Gas flow dynamics and air-to-fuel ratio adjustment

- Troubleshooting common burner malfunctions

5. Practice Common Interview Questions

In addition to technical questions, prepare for common interview questions that assess your communication, problem-solving, and teamwork skills.

- “Tell me about a time you faced a challenging situation and how you overcame it.”

- “Why are you interested in this role and how do your skills align with the job requirements?”

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Gas Burner Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.