Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Gasket Former position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

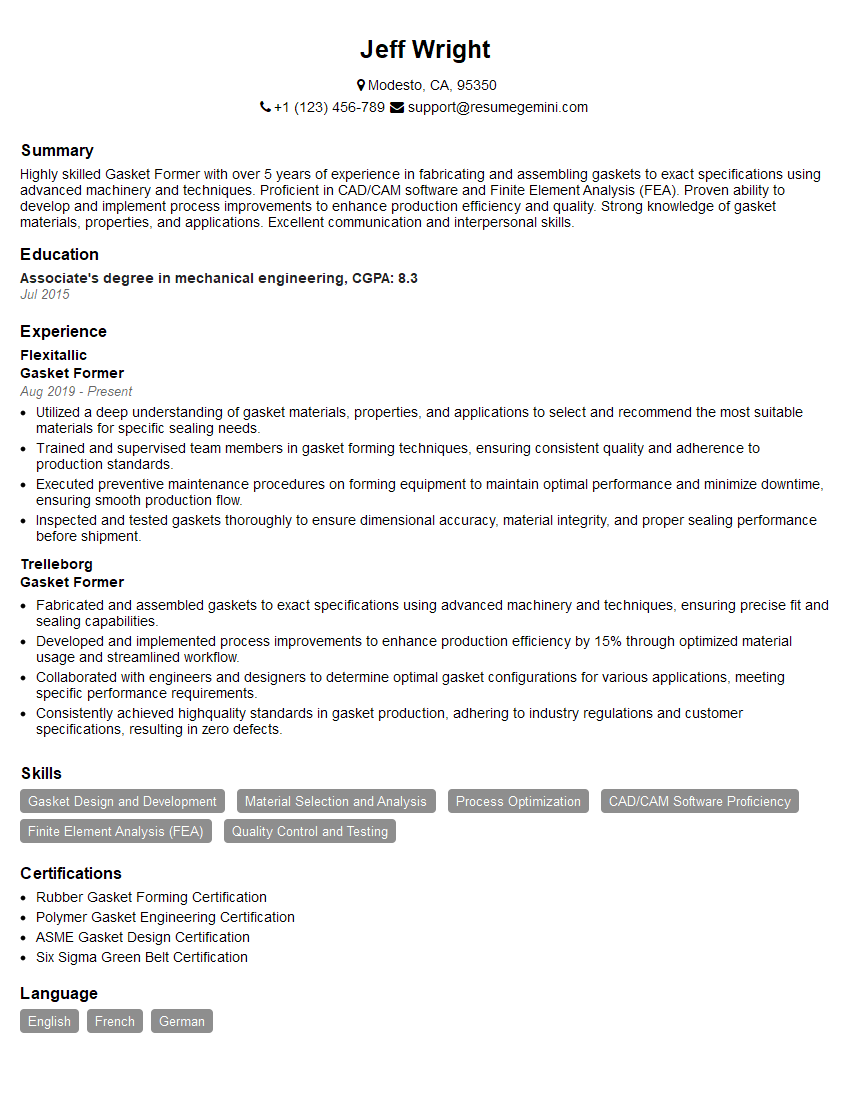

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Gasket Former

1. Explain the different types of gasket materials and their applications?

There are various types of gasket materials, each with its own unique properties and applications.

- Elastomeric gaskets: These gaskets are made of rubber or rubber-like materials and are highly flexible and resistant to compression. They are commonly used in automotive and industrial applications.

- Metallic gaskets: These gaskets are made of metal, such as steel, aluminum, or copper, and are used in high-pressure and high-temperature applications. They are strong and durable, but not as flexible as elastomeric gaskets.

- Semi-metallic gaskets: These gaskets are a combination of metallic and non-metallic materials, providing a balance of strength, flexibility, and temperature resistance. They are often used in industrial applications.

- Plastic gaskets: These gaskets are made of plastic materials, such as polyethylene or Teflon, and are resistant to chemicals and corrosion. They are often used in chemical processing and pharmaceutical applications.

2. What are the key factors to consider when selecting a gasket material?

Material Compatibility:

- Ensuring the gasket material is compatible with the fluids, gases, or chemicals it will be exposed to.

- Considering factors such as temperature, pressure, and chemical resistance.

Gasket Design:

- Matching the gasket material to the specific design requirements, such as shape, thickness, and sealing surface.

- Considering factors like flexibility, compressibility, and recovery.

Application Environment:

- Evaluating the operating conditions of the application, including temperature, pressure, vibration, and potential exposure to corrosive substances.

- Selecting a gasket material that can withstand the specific environmental factors.

3. Describe the process of cutting and forming gaskets?

Cutting and forming gaskets involves several steps to achieve the desired shape and dimensions:

- Material Selection: Choosing the appropriate gasket material based on its properties and application requirements.

- Pattern Creation: Creating a template or pattern that outlines the desired gasket shape and dimensions.

- Cutting: Using specialized cutting tools, such as a die press, water jet, or laser cutter, to cut the gasket material according to the pattern.

- Forming: Shaping the cut gasket material to fit the specific application, using techniques like molding, stamping, or bending.

- Finishing: Completing the gasket by applying treatments or coatings for improved performance or aesthetics.

4. What are the common defects that can occur during gasket manufacturing and how can they be prevented?

Common defects in gasket manufacturing include:

- Dimensional inaccuracies: Deviations from specified dimensions due to improper cutting or forming.

- Material flaws: Defects in the gasket material, such as cracks, voids, or inclusions.

- Surface imperfections: Uneven surfaces or scratches that can affect sealing performance.

- Bonding issues: Improper adhesion between the gasket and the mating surfaces.

Prevention measures:

- Using high-quality materials and precise manufacturing processes.

- Implementing quality control measures throughout the production process.

- Properly training and certifying operators.

5. Explain the importance of proper gasket installation and what potential problems can arise from incorrect installation?

Proper gasket installation is crucial to ensure effective sealing and prevent premature failure.

- Clean surfaces: Mating surfaces must be clean and free of contaminants to ensure proper gasket adhesion.

- Correct positioning: The gasket should be accurately positioned between the mating surfaces according to the specified orientation.

- Appropriate torque: Bolts or fasteners should be tightened to the specified torque to ensure proper compression and sealing.

- No overtightening: Excessive torque can damage the gasket or the mating surfaces.

Potential problems from incorrect installation:

- Leaks: Improper sealing due to gaps or misalignment.

- Gasket failure: Damage caused by overtightening or improper positioning.

- Equipment damage: Leaks or gasket failure can lead to costly repairs or downtime.

6. Describe the different types of gasket testing methods and their applications?

Gasket testing methods evaluate the performance and quality of gaskets:

- Pressure testing: Simulating operating conditions to check for leaks and assess sealing performance.

- Tensile testing: Measuring the gasket’s resistance to stretching and deformation.

- Compression testing: Determining the gasket’s ability to withstand compression and maintain sealing.

- Environmental testing: Exposing gaskets to extreme temperatures, chemicals, or other environmental factors to assess durability.

7. What are the key quality control measures implemented in gasket manufacturing?

- Raw material inspection: Verifying the quality of incoming materials.

- Process monitoring: Monitoring production processes to ensure adherence to specifications.

- Dimensional inspection: Measuring gaskets to ensure they meet dimensional requirements.

- Performance testing: Conducting tests to assess gasket performance, such as pressure testing.

- Documentation and traceability: Maintaining records of production and testing to ensure traceability.

8. How do you stay updated with the latest advancements in gasket technology and industry best practices?

- Industry conferences and exhibitions: Attending industry events to learn about new technologies and network with experts.

- Technical journals and publications: Reading industry-specific publications to stay informed about research and developments.

- Online resources and webinars: Utilizing online platforms and webinars to access the latest information and training.

- Collaboration with suppliers and partners: Engaging with suppliers and industry partners to gain insights into emerging trends.

9. Can you describe a challenging gasket design or manufacturing project you have worked on and how you overcame the challenges?

- Project description: Briefly outline the project, its challenges, and the specific requirements.

- Problem-solving approach: Explain the steps taken to identify and address the challenges, including research, experimentation, or collaboration.

- Innovative solutions: Describe any innovative solutions or techniques used to overcome the challenges and achieve project success.

- Lessons learned: Share the insights and learnings gained from the project that have enhanced your expertise.

10. What are your strengths and weaknesses as a Gasket Former and how do they align with the requirements of this role?

- Strengths: Highlight relevant skills, experiences, and qualifications that make you a suitable candidate for the role, such as expertise in gasket design, manufacturing techniques, and quality control.

- Weaknesses: Acknowledge any areas where you may need improvement and explain how you plan to address them, such as seeking additional training or developing specific skills.

- Alignment: Demonstrate how your strengths and weaknesses align with the requirements of the role and how you can contribute to the company’s goals.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Gasket Former.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Gasket Former‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Gasket Former is responsible for the production of gaskets, which are essential components in various industries for sealing and preventing leaks. Their key responsibilities include:

1. Prepare and Monitor Gasket Forming Machines

Set up and operate gasket forming machines, ensuring they are properly calibrated and running smoothly.

- Monitor machine performance and make adjustments as needed to maintain optimal operation.

- Troubleshoot and resolve any technical issues with the machines.

2. Cut and Shape Gasket Materials

Cut and shape gasket materials, such as rubber, cork, or metal, using specialized tools and equipment.

- Follow prescribed specifications and blueprints to cut the gaskets to precise dimensions.

- Ensure the gaskets meet the required tolerances and quality standards.

3. Assemble and Inspect Gaskets

Assemble and inspect gaskets, ensuring they are free of defects and meet the dimensional requirements.

- Assemble gaskets using adhesives, bolts, or other methods, as per the design specifications.

- Inspect gaskets visually and using measuring instruments to verify their accuracy and quality.

4. Maintain Work Area and Inventory

Maintain a clean and organized work area, ensuring adherence to safety protocols.

- Keep inventory of gasket materials and finished products, ensuring timely replenishment.

- Follow established quality control procedures and document all relevant data.

Interview Preparation Tips

To ace an interview for a Gasket Former position, candidates should focus on preparing in the following areas:

1. Technical Skills and Knowledge

Thoroughly review the job description and research the specific gasket forming processes and equipment used by the company.

- Be prepared to discuss your understanding of gasket materials, cutting techniques, and assembly methods.

- Highlight any experience or certifications you have in operating gasket forming machines or working with industrial materials.

2. Quality-Oriented Mindset

Emphasize your commitment to quality and precision in your work. Explain how you maintain a clean and organized work environment and follow established quality control procedures.

- Provide examples of how you have identified and resolved quality issues in previous roles.

- Discuss your understanding of the importance of accurate gasket fabrication in various industries.

3. Attention to Detail and Safety

Highlight your strong attention to detail and adherence to safety protocols. Explain how you ensure the accuracy of gasket dimensions and meet safety requirements in your work.

- Describe your experiences in using measuring instruments and following safety guidelines.

- Discuss how you prioritize safety in your work and identify potential hazards in your work environment.

4. Problem-Solving and Teamwork

Be prepared to share examples of how you have solved problems and worked effectively in a team setting.

- Explain how you troubleshoot and resolve technical issues with gasket forming machines.

- Discuss your experience in collaborating with colleagues to achieve common objectives.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Gasket Former interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.