Feeling lost in a sea of interview questions? Landed that dream interview for Gear Machinist but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Gear Machinist interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

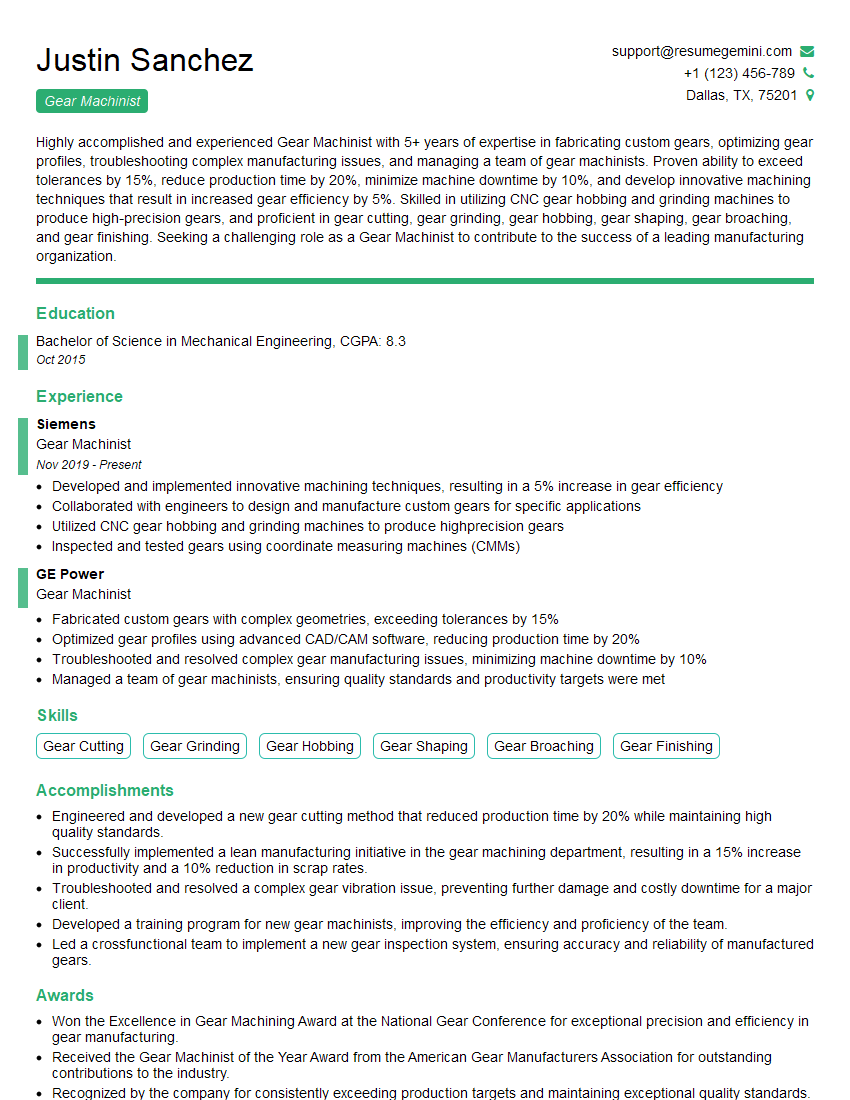

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Gear Machinist

1. What are the key steps involved in gear manufacturing?

The key steps involved in gear manufacturing are:

- Material selection

- Forging or casting of the gear blank

- Machining of the gear teeth

- Heat treatment

- Inspection and testing

2. Describe the different types of gear cutting methods?

Hobbing

- Single-tooth cutting process

- High production rates

- Suitable for a wide range of gear sizes and materials

Shaping

- Reciprocating cutting process

- Higher accuracy and finish compared to hobbing

- Suitable for smaller gear sizes

Milling

- Rotary cutting process

- Can produce gears with complex tooth profiles

- Slower production rates compared to hobbing and shaping

3. What are the common materials used in gear manufacturing?

- Steel

- Iron

- Aluminum

- Bronze

- Nylon

4. Explain the importance of gear backlash?

Gear backlash is the amount of play between mating gear teeth. It is important to control backlash to ensure smooth gear operation, reduce noise, and prevent premature wear.

5. What are the different methods of backlash measurement?

- Dial indicator method

- Tooth contact measurement

- Optical measurement

6. Describe the process of gear heat treatment?

Gear heat treatment is a critical process that improves the mechanical properties of gears, including hardness, strength, and wear resistance. The most common heat treatment methods are:

- Carburizing

- Nitriding

- Induction hardening

7. What are the different types of gear finishes?

- Ground

- Shaved

- Honed

- Lapped

8. Explain the concept of gear tooth profile modification?

Gear tooth profile modification is a technique used to adjust the shape of gear teeth to improve performance characteristics, such as:

- Reducing noise

- Improving load capacity

- Increasing efficiency

9. What is AGMA?

AGMA (American Gear Manufacturers Association) is a trade association that promotes the interests of the gear industry. AGMA develops standards, provides education, and promotes research in the field of gear technology.

10. Describe your experience with CMM inspection of gears

In my previous role, I was responsible for CMM inspection of gears using a variety of techniques, including:

- Contact measurement

- Non-contact measurement

- Gear tooth profile measurement

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Gear Machinist.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Gear Machinist‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Gear Machinists play a pivotal role in the manufacturing industry, utilizing specialized equipment and techniques to produce precision parts for various applications. Their key responsibilities include:

1. Setting up and Operating CNC Gear Cutting Machines

Setting up and operating computerized numerically controlled (CNC) gear cutting machines is a core responsibility. This involves programming the machines, ensuring accurate tool selection and positioning, and monitoring the cutting process to achieve desired gear specifications.

- Program CNC machines to execute specific cutting patterns and toolpaths.

- Select and install appropriate cutting tools, ensuring precise dimensions and surface finishes.

- Supervise and monitor machine operations, adjusting parameters as needed to optimize cutting efficiency.

2. Interpreting Engineering Drawings and Documents

Reading and understanding engineering drawings and manufacturing specifications is essential for gear machinists. They must accurately interpret these documents to determine cutting requirements and ensure product conformity.

- Analyze engineering drawings to determine gear specifications, including dimensions, tolerances, and surface finishes.

- Identify and interpret manufacturing procedures, following instructions precisely to produce high-quality parts.

- Communicate with engineers and other team members to clarify requirements and troubleshoot any issues.

3. Maintaining Machines and Tools

Gear machinists are responsible for maintaining and calibrating the equipment they use. This includes performing routine inspections, cleaning, and lubrication, as well as identifying and resolving any potential issues.

- Conduct regular maintenance and inspection of CNC machines, including lubrication, cleaning, and minor repairs.

- Calibrate machines and tools to ensure accuracy and precision in cutting operations.

- Troubleshoot and resolve machine malfunctions, minimizing downtime and ensuring efficient production.

4. Inspecting and Measuring Gears

Verifying the quality and accuracy of produced gears is a critical task for gear machinists. They employ various measuring tools and techniques to ensure that the gears meet required specifications.

- Perform quality control inspections, using measuring instruments such as micrometers, calipers, and gear testers.

- Calibrate measuring equipment regularly to maintain accuracy and reliability.

- Document inspection results and provide feedback to improve production processes and maintain quality standards.

Interview Tips

To excel in a gear machinist interview, it’s crucial to demonstrate your technical skills, attention to detail, and problem-solving abilities. Here are some tips to help you ace the interview:

1. Research the Company and Position

Thoroughly research the company and the specific gear machinist position you’re applying for. This will help you understand their products, culture, and the specific requirements of the role.

- Visit the company website to learn about their history, mission, and products.

- Read industry publications and attend webinars to stay updated on the latest trends and technologies in gear manufacturing.

2. Prepare for Technical Questions

Expect to be asked technical questions related to gear manufacturing, CNC machine operation, and quality control procedures. Be prepared to discuss your experience and demonstrate your understanding of these concepts.

- Review basic gear terminology and manufacturing processes.

- Practice programming and operating CNC machines using industry-standard software.

- Familiarize yourself with different types of measuring instruments and inspection techniques used in gear manufacturing.

3. Highlight Your Skills and Experience

During the interview, confidently articulate your skills, experience, and why you’re a suitable candidate for the position. Quantify your accomplishments whenever possible to demonstrate your impact.

- Emphasize your expertise in CNC machine operation, including specific software and equipment you’re proficient with.

- Highlight your ability to read and interpret engineering drawings and technical specifications.

- Provide examples of your problem-solving skills and how you overcame challenges in previous roles.

4. Ask Thoughtful Questions

Asking thoughtful questions at the end of the interview shows your interest and engagement. Prepare questions about the company’s goals, the team you’ll be working with, and opportunities for professional development.

- Inquire about the company’s long-term plans and how the gear machinist role contributes to those goals.

- Ask about the team culture and the collaborative environment you can expect.

- Express your interest in training and advancement opportunities within the organization.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Gear Machinist role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.