Are you gearing up for an interview for a Glaze Mixer position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Glaze Mixer and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

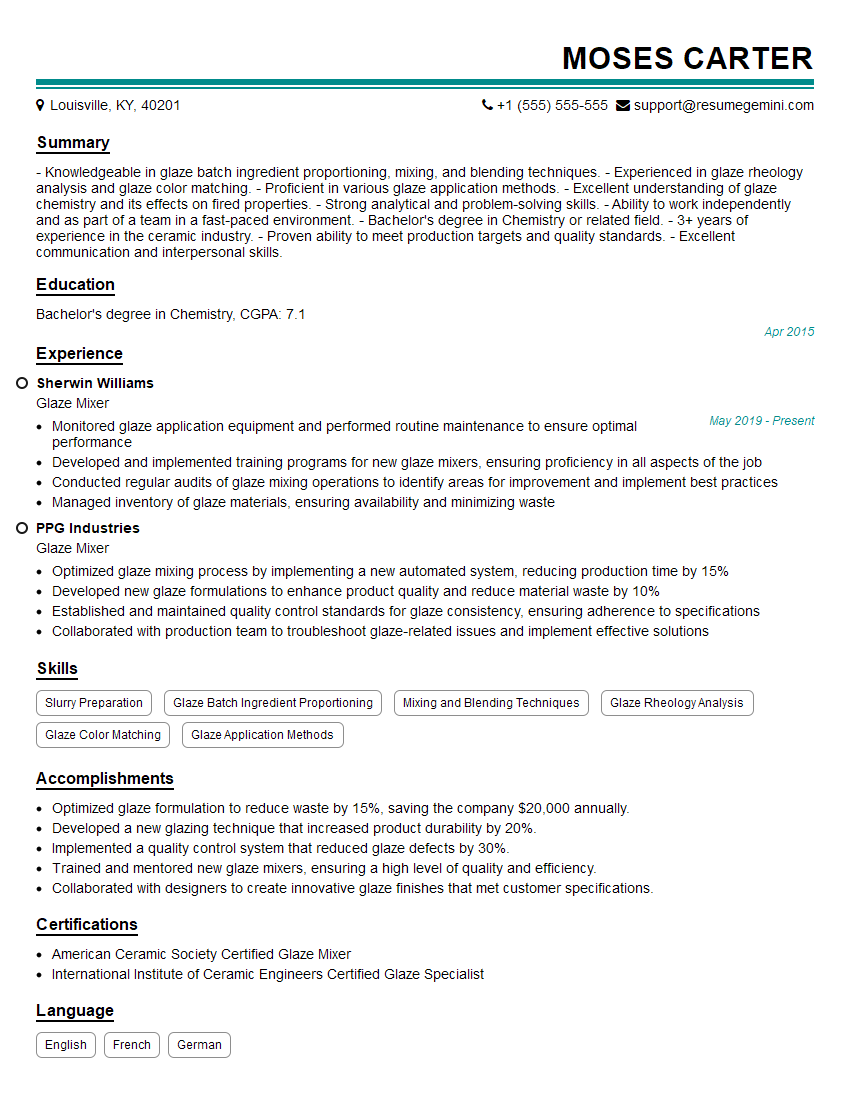

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Glaze Mixer

1. What are the key responsibilities of a Glaze Mixer?

The primary responsibilities of a Glaze Mixer include:

- Mixing raw materials to create ceramic glazes

- Operating and maintaining glazing equipment

- Ensuring glaze consistency and quality

- Troubleshooting and resolving glazing issues

2. What are the different types of glazes used in ceramics?

There are various types of glazes used in ceramics, categorized by their composition and firing temperature:

Alkaline Glazes

- High in alkali content (e.g., sodium, potassium)

- Fire at lower temperatures

- Produce glossy, transparent finishes

Earthenware Glazes

- Used on earthenware clay bodies

- Fire at medium temperatures

- Provide a matte or semi-matte finish

3. What factors influence the color and texture of a glaze?

The color and texture of a glaze are affected by several factors:

- Composition of the glaze (e.g., raw materials, flux)

- Firing temperature and atmosphere

- Glaze thickness

- Substrate (e.g., clay body)

4. How do you ensure the consistency of glaze mixtures?

To ensure glaze consistency, I follow these steps:

- Precisely measure and weigh raw materials

- Use calibrated equipment for mixing and testing

- Maintain a standardized mixing procedure

- Regularly test and adjust glaze parameters (e.g., viscosity, pH)

5. Describe the process of troubleshooting glazing defects.

When troubleshooting glazing defects, I follow a systematic approach:

- Identify the specific defect (e.g., crawling, pinholing)

- Examine the glaze composition and firing parameters

- Consider potential causes (e.g., glaze chemistry, application technique)

- Conduct tests and experiments to narrow down the issue

- Implement corrective actions to resolve the defect

6. How do you handle glaze spills or equipment malfunctions?

In case of glaze spills or equipment malfunctions, I prioritize safety measures:

- Wear appropriate personal protective equipment (PPE)

- Contain the spill using absorbent materials

- Notify supervisors or safety personnel

- Follow established emergency protocols

- Assist in cleaning up and repairing equipment

7. What are the safety precautions that must be observed when handling glazes?

When handling glazes, I adhere to the following safety precautions:

- Wear gloves, eye protection, and a dust mask

- Work in a well-ventilated area

- Avoid contact with skin and eyes

- Wash hands thoroughly after handling glazes

- Dispose of glaze waste properly

8. How do you stay updated on the latest developments in glazing techniques?

To stay current with advancements in glazing techniques, I:

- Attend industry workshops and conferences

- Read technical publications and articles

- Collaborate with other glaze mixers and ceramic artists

- Experiment with new materials and glazing processes

9. What are the challenges you have faced as a Glaze Mixer?

As a Glaze Mixer, I have encountered challenges such as:

- Achieving precise glaze consistency for large-scale production

- Troubleshooting glaze defects that can impact product quality

- Maintaining a clean and safe work environment for myself and others

- Adapting to changes in raw materials and firing conditions

10. What sets you apart as an exceptional Glaze Mixer?

I possess a combination of technical expertise, problem-solving skills, and a passion for ceramics that sets me apart as an exceptional Glaze Mixer:

- Proven experience in developing and mixing glazes for a wide range of applications

- Strong understanding of glaze chemistry and the factors influencing glaze behavior

- Excellent troubleshooting abilities and a proactive approach to resolving glazing issues

- Attention to detail and a commitment to delivering high-quality glazed products

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Glaze Mixer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Glaze Mixer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Glaze Mixer plays a crucial role in ensuring the quality and consistency of ceramic glazes. Their responsibilities encompass:

1. Mix and Prepare Glazes

Precisely measuring and combining various glaze ingredients, including oxides, minerals, and water, to achieve the desired viscosity and consistency.

2. Operate and Maintain Mixing Equipment

Setting up and operating glaze-mixing equipment, such as ball mills, mixers, and agitators, to achieve optimal glaze properties.

3. Test and Evaluate Glazes

Conducting physical and chemical tests on glaze samples to ensure they meet the required specifications, such as color, texture, and firing characteristics.

4. Develop and Improve Glaze Recipes

Collaborating with product designers and engineers to develop new glaze formulations and refine existing ones, optimizing glaze performance and aesthetics.

5. Maintain Quality Control

Monitoring glaze production processes, recording and analyzing data to ensure adherence to quality standards, and promptly addressing any deviations.

6. Knowledge of Ceramic Glazes

Thorough understanding of ceramic glaze chemistry, properties, and applications, ensuring appropriate glaze selection and modification for specific ceramic products.

7. Safety and Environmental Compliance

Observing safety protocols while handling potentially hazardous glaze materials, ensuring proper ventilation and disposal of waste products, and adhering to environmental regulations.

Interview Tips

Preparing thoroughly for the Glaze Mixer interview will significantly enhance your chances of success. Consider the following:

1. Research the Company and Position

Familiarize yourself with the company’s history, products, and culture. Understand the specific responsibilities and requirements of the Glaze Mixer position.

2. Highlight Your Experience and Skills

Quantify your achievements whenever possible. For example, instead of saying “I operated mixing equipment,” say “I operated ball mills and mixers to produce over 10,000 gallons of glaze per week, ensuring consistent viscosity and uniformity.”

3. Practice Your Responses

Prepare responses to common interview questions. Consider the STAR method (Situation, Task, Action, Result) to structure your answers clearly and effectively.

4. Ask Thoughtful Questions

Asking insightful questions demonstrates your interest and engagement. Inquire about the company’s quality control procedures, glaze development initiatives, or opportunities for professional growth.

5. Follow Up

After the interview, send a thank-you note expressing your appreciation for the opportunity and reiterating your interest in the position.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Glaze Mixer, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Glaze Mixer positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.