Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Grain Elevator Man interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Grain Elevator Man so you can tailor your answers to impress potential employers.

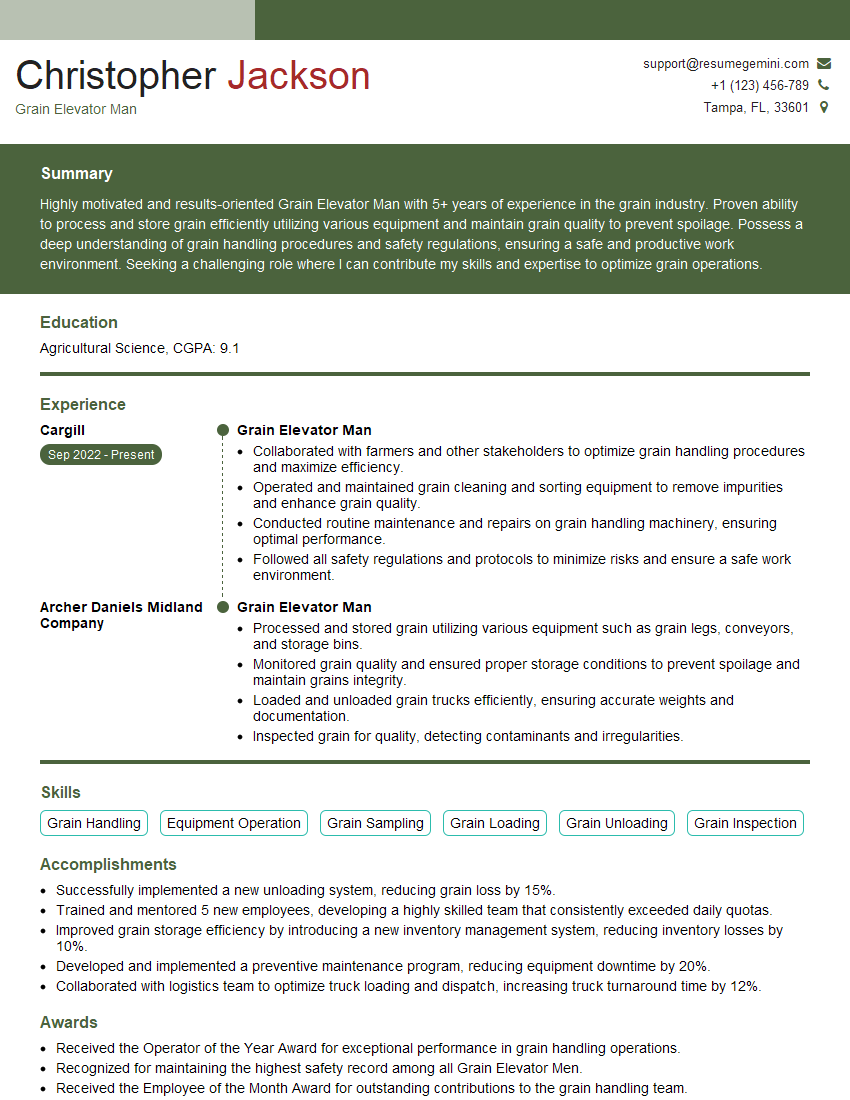

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Grain Elevator Man

1. What are the key duties and responsibilities of a Grain Elevator Man?

The Grain Elevator Man is responsible for a wide range of responsibilities involving the storage, handling, and transportation of grain.

- Load and unload grain from trucks, railcars, barges, and other transportation vehicles.

- Operate equipment to transfer, clean, and store grain.

- Monitor and maintain temperature and humidity levels in storage areas.

- Conduct regular inspections of equipment, buildings, and grounds.

- Keep detailed records related to crop conditions, grain quality, and movement.

- Adhere to safety protocols and maintain a clean and organized work environment.

2. Describe the different types of grain handling equipment used in your role.

- Conveyors: Used to transport grain from one area to another.

- Elevators: Lift and move grain vertically.

- Loading and unloading equipment: Includes augers, spouts, and chutes.

- Cleaning and grading equipment: Removes impurities and sorts grain according to quality.

- Storage equipment: Includes silos, bins, and warehouses.

- Monitoring and control systems: Track temperature, moisture, and other parameters.

3. Explain the importance of maintaining proper temperature and humidity levels in grain storage areas.

Temperature and humidity can significantly impact the quality and shelf life of grain. High temperatures can cause spoilage and insect infestations, while excessively low temperatures can damage seed viability. Maintaining optimal humidity levels prevents moisture loss and preserves grain condition.

- Optimizing grain quality and nutritional value

- Preventing insect infestation and mold growth

- Preserving seed viability for planting

- Reducing energy consumption

- Minimizing storage losses and spoilage

4. Describe the steps involved in conducting grain quality inspections.

Grain quality inspections are crucial for ensuring the safety, quality, and market value of the crop.

- Visual inspection: Examining grain for color, texture, and foreign material.

- Sampling: Collecting representative samples for laboratory analysis.

- Moisture testing: Determining grain moisture content to assess shelf life.

- Impurities analysis: Identifying and quantifying non-grain components, such as dirt, dust, and weed seeds.

- Grading: Classifying grain according to established quality standards.

- Documentation: Recording and reporting inspection results for quality control and regulatory compliance.

5. Explain the importance of safety in the grain elevator industry.

Grain elevators present unique safety hazards due to heavy machinery, rotating equipment, and stored grain. Implementing and adhering to safety protocols is crucial for preventing accidents and maintaining a healthy work environment.

- Personal protective equipment: Wearing appropriate clothing, gloves, and eye protection.

- Safe operating procedures: Following established guidelines for equipment usage.

- Equipment inspections: Regularly checking and maintaining machinery to prevent failures.

- Emergency procedures: Knowing evacuation routes and response protocols in case of accidents.

- Training and awareness: Providing comprehensive training and promoting safety awareness among employees.

6. Describe your experience in troubleshooting and repairing grain handling equipment.

Troubleshooting and repairing grain handling equipment is a critical aspect of ensuring efficient operation and preventing breakdowns. Experience in identifying and resolving common issues is essential.

- Electrical troubleshooting: Identifying and fixing electrical faults in conveyors, elevators, and other equipment.

- Mechanical repairs: Servicing and replacing parts in motors, bearings, and other mechanical components.

- Hydraulic system maintenance: Diagnosing and resolving issues with hydraulic systems used in conveyors and other equipment.

- Troubleshooting conveyor systems: Identifying and fixing problems with belt alignment, tension, and drive mechanisms.

- Preventive maintenance: Regularly inspecting and servicing equipment to prevent failures.

7. Explain your understanding of the different types of grain conditioning and preservation methods.

Grain conditioning and preservation techniques are used to maintain the quality and viability of stored grain. Understanding these methods and their applications is essential for effective crop management.

- Aeration: Circulating air to control temperature and moisture levels.

- Drying: Removing excess moisture from grain to prevent spoilage.

- Cooling: Lowering grain temperature to inhibit insect infestations and maintain quality.

- Fumigation: Using chemical treatments to control insect pests.

- Controlled atmosphere storage: Maintaining specific gas mixtures to extend grain shelf life.

8. Describe the role of technology in modern grain elevator operations.

Technology has significantly transformed grain elevator operations, improving efficiency, safety, and productivity.

- Automated control systems: Regulating equipment functions and monitoring grain flow.

- Data loggers and sensors: Tracking temperature, moisture, and other critical parameters in real-time.

- Precision agriculture techniques: Utilizing data to optimize grain production and management practices.

- Communication systems: Facilitating communication between equipment, operators, and remote locations.

- Safety monitoring devices: Detecting hazards and triggering alarms in case of emergencies.

9. Explain how you handle working in a physically demanding and repetitive environment.

Working in a grain elevator requires physical stamina and the ability to perform repetitive tasks. Candidates should demonstrate their capacity to work effectively in this demanding environment.

- Physical fitness: Maintaining physical fitness through regular exercise and a healthy lifestyle.

- Ergonomic techniques: Using proper body mechanics to reduce strain and fatigue.

- Planned breaks: Taking regular breaks to rest and recover.

- Hydration and nutrition: Staying hydrated and eating a nutritious diet to sustain energy levels.

10. Describe your experience in working with a team in a grain elevator setting.

Grain elevator operations rely on teamwork and collaboration. Candidates should highlight their ability to work effectively as part of a team.

- Communication: Clearly conveying information and instructions to team members.

- Coordination: Collaborating with others to achieve common goals.

- Problem-solving: Working together to identify and resolve issues.

- Respect: Treating team members with respect and valuing their contributions.

- Support: Assisting and supporting colleagues whenever needed.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Grain Elevator Man.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Grain Elevator Man‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Grain Elevator Men play a crucial role in the grain handling process, ensuring the safe and efficient operation of grain elevators. Their main responsibilities include:

1. Grain Handling and Storage

Loading, unloading, and conveying grain using various equipment such as augers, conveyors, and grain legs.

- Maintaining and inspecting grain storage bins and silos to ensure their proper functioning.

- Monitoring grain temperature and moisture levels to prevent spoilage and maintain grain quality.

2. Equipment Maintenance and Repair

Inspecting, maintaining, and repairing grain handling equipment, including augers, conveyors, and grain legs.

- Troubleshoot and resolve mechanical issues to ensure smooth operation of the elevator.

- Perform routine maintenance and lubrication to prevent equipment breakdowns.

3. Safety and Compliance

Adhering to all safety regulations and protocols to ensure a safe work environment.

- Inspecting and maintaining safety equipment such as fire extinguishers and warning signs.

- Reporting any potential hazards or safety concerns to supervisors and colleagues.

4. General Operations

Performing general maintenance and cleaning tasks around the elevator.

- Keeping work areas clean and organized to maintain a safe and efficient workspace.

- Assisting with other tasks as assigned by supervisors.

Interview Preparation Tips

Preparing thoroughly for an interview as a Grain Elevator Man can significantly increase your chances of success. Here are some helpful tips:

1. Research the Company and Role

Familiarize yourself with the company’s background, operations, and the specific requirements of the Grain Elevator Man position.

- Visit the company website and read through their mission statement, values, and current projects.

- Check industry publications and online resources to gather information about the role and the industry in general.

2. Highlight Relevant Skills and Experience

Emphasize your skills and experience that align with the job responsibilities of a Grain Elevator Man.

- Highlight your experience in grain handling, equipment maintenance, and safety procedures.

- Quantify your accomplishments with specific metrics and examples to demonstrate your impact.

3. Practice Answering Common Interview Questions

Prepare thoughtful responses to common interview questions that you may encounter.

- Tell me about your experience in grain handling.

- Describe a time when you faced a challenge while operating grain handling equipment.

- How do you ensure safety in a grain elevator environment?

4. Prepare Questions for the Interviewer

Asking well-thought-out questions at the end of the interview demonstrates your interest in the role and the company.

- Inquire about the company’s plans for expanding its grain handling operations.

- Ask about the safety protocols and training provided by the company.

- Seek information about opportunities for career growth within the organization.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Grain Elevator Man interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.