Are you gearing up for an interview for a Grain Mixer position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Grain Mixer and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

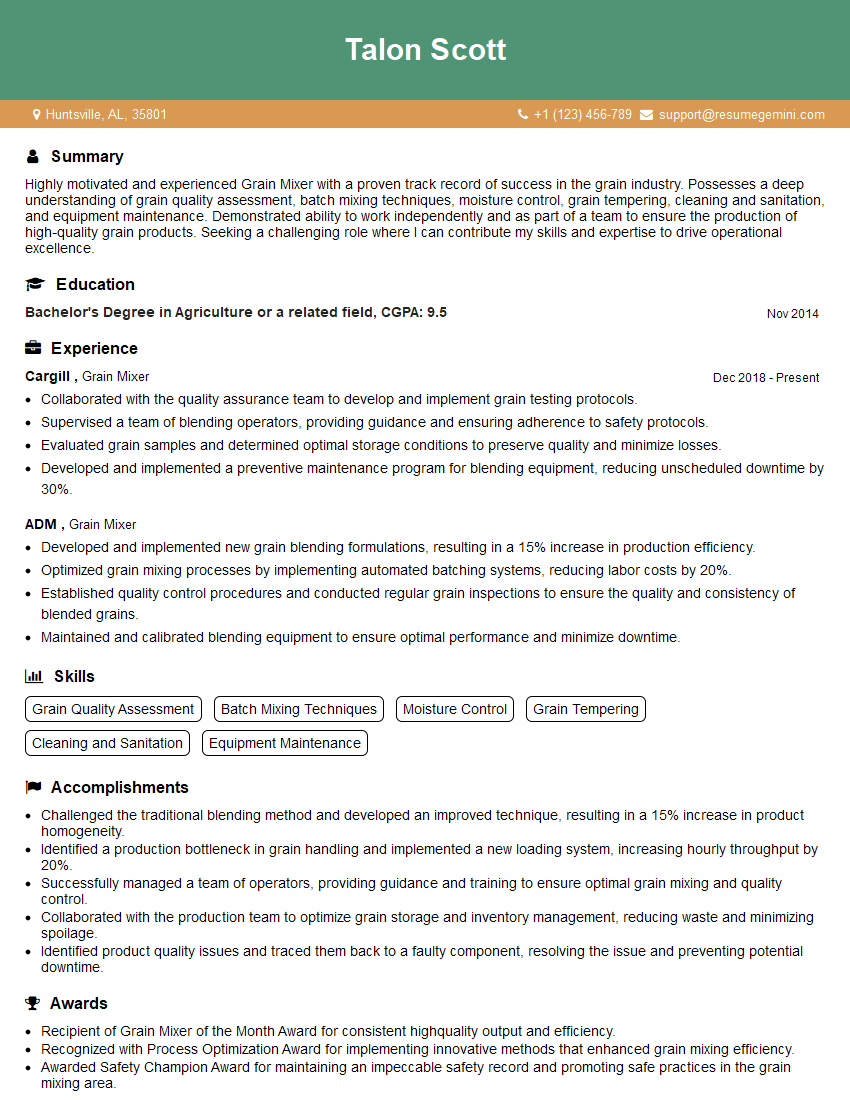

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Grain Mixer

1. Describe the process of grain mixing, and what are the key factors that affect the quality of the mix?

The process of grain mixing involves combining different types and varieties of grains to create a uniform blend that meets specific quality standards. Several key factors influence the quality of the mix:

- Grain selection: Choosing grains with consistent quality, moisture content, and protein levels is crucial.

- Mixing ratios: Determining the optimal proportions of each grain based on desired specifications.

- Mixing equipment: Utilizing suitable mixers that ensure thorough and consistent blending.

- Mixing time: Allowing sufficient time for the grains to be thoroughly mixed without overmixing.

- Environmental conditions: Maintaining proper temperature and humidity levels to prevent moisture changes or grain damage.

2. How do you ensure the accuracy and consistency of the grain mix?

Quality Control Measures

- Regular sampling: Taking representative samples throughout the mixing process to assess quality.

- Laboratory analysis: Conducting tests to determine moisture content, protein levels, and other key parameters.

- Calibration: Regularly calibrating weighing and mixing equipment to maintain accuracy.

Standard Operating Procedures

- Documented procedures: Establishing clear guidelines for grain selection, mixing ratios, equipment operation, and quality control.

- Training: Providing comprehensive training to operators to ensure they follow procedures and best practices.

3. How do you troubleshoot common problems that may arise during grain mixing?

- Uneven mixing: Adjusting mixing time, equipment settings, or grain ratios as needed.

- Moisture variations: Conducting moisture analysis and adjusting blending ratios to ensure desired moisture content.

- Equipment malfunctions: Troubleshooting and repairing equipment promptly to minimize downtime and maintain accuracy.

- Pest infestation: Implementing pest control measures and maintaining proper storage conditions.

- Quality deviations: Identifying the source of deviations through sampling and analysis, and taking corrective actions to prevent recurrence.

4. Can you describe different types of grain mixers and their respective advantages and disadvantages?

- Horizontal mixers: Uniform mixing, suitable for large volumes, but can be slow.

- Vertical mixers: Faster mixing, but may produce less uniform blends.

- Ribbon mixers: Gentle mixing, suitable for delicate grains, but may have lower capacities.

- Paddle mixers: Aggressive mixing, efficient for heavy grains, but may cause grain breakage.

- Continuous mixers: Automated and continuous operation, but require precise control to maintain consistency.

5. What are the safety precautions that must be observed when operating grain mixing equipment?

- Lockout/tagout procedures: Ensuring equipment is isolated before maintenance or repairs.

- Proper ventilation: Maintaining adequate ventilation to prevent dust accumulation and inhalation.

- Fall protection: Using ladders and platforms with proper safety measures.

- Personal protective equipment: Wearing appropriate clothing, gloves, and respirators.

- Training and supervision: Providing comprehensive training and ensuring proper supervision for operators.

6. What are the quality standards and regulations that apply to grain mixing?

- Food safety regulations: Adhering to guidelines set by regulatory bodies to ensure food safety and prevent contamination.

- Grain industry standards: Following established industry standards for grain quality, blending, and storage.

- Customer specifications: Meeting specific requirements and quality parameters set by customers.

- Internal quality control protocols: Implementing company-specific quality control measures to ensure consistent production.

7. How do you stay up-to-date on the latest technologies and best practices in grain mixing?

- Industry conferences and seminars: Participating in industry events to learn about new technologies and advancements.

- Trade publications and online resources: Reading industry journals and accessing reputable online sources for information.

- Collaboration with suppliers and experts: Consulting with equipment manufacturers and other industry professionals.

- Continuing education: Taking courses or workshops to enhance knowledge and skills.

8. How do you manage and optimize the efficiency of grain mixing operations?

- Production scheduling: Planning and coordinating mixing activities to maximize equipment utilization.

- Inventory management: Maintaining optimal grain inventory levels to avoid shortages or overstocking.

- Equipment maintenance: Implementing regular maintenance and calibration schedules to ensure equipment reliability.

- Process optimization: Analyzing mixing parameters and adjusting settings to improve efficiency and quality.

- Performance monitoring: Tracking key performance indicators to identify areas for improvement.

9. How do you ensure the proper storage and handling of grain before and after mixing?

- Temperature and humidity control: Maintaining appropriate storage conditions to prevent grain deterioration.

- Pest control: Implementing measures to prevent pest infestations and contamination.

- FIFO (First In, First Out): Rotating inventory to prevent older grain from becoming stale.

- Proper handling techniques: Using clean equipment and minimizing grain damage during handling.

- Regular inspections: Conducting periodic inspections to monitor grain quality and storage conditions.

10. Describe your experience in working with different types of grain and the challenges you have encountered.

Throughout my career, I have worked with a wide range of grains, each presenting unique characteristics and challenges:

- Wheat: Ensuring consistent protein content and gluten strength for baking applications.

- Corn: Maintaining moisture levels and preventing mold growth during storage.

- Soybeans: Optimizing mixing ratios to achieve desired protein and oil content.

- Barley: Controlling humidity and preventing sprouting during malting processes.

- Specialty grains: Understanding the specific requirements and quality parameters of niche grains.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Grain Mixer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Grain Mixer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Grain Mixers play a vital role in the agricultural industry, ensuring the production of high-quality mixed grains for various purposes. Their key job responsibilities include:

1. Grain Handling and Preparation

Preparing and handling different types of grains, such as corn, wheat, and soybeans, by receiving, inspecting, and storing them.

- Monitoring grain quality and ensuring adherence to specifications.

- Utilizing equipment such as grain elevators, conveyors, and storage bins.

2. Mixing and Blending

Operating grain mixing equipment to create specific blends of grains according to customer or production requirements.

- Determining the appropriate ratios and quantities of different grains.

- Monitoring and adjusting mixing parameters to achieve desired consistency and quality.

3. Quality Control and Maintenance

Maintaining high standards of grain quality and ensuring adherence to safety and hygiene regulations.

- Conducting regular quality checks and inspections to identify and address any discrepancies.

- Maintaining and calibrating mixing equipment to ensure optimal performance.

4. Inventory Management

Monitoring and managing grain inventory levels, including receiving, storing, and issuing.

- Maintaining accurate records of grain transactions and inventory levels.

- Coordinating with other departments to ensure timely delivery and availability of grains.

5. Equipment Maintenance and Troubleshooting

Performing preventive maintenance and troubleshooting on grain mixing equipment to minimize downtime.

- Identifying and resolving equipment malfunctions.

- Coordinating with maintenance personnel for major repairs and upgrades.

6. Safety and Compliance

Adhering to safety regulations and protocols to ensure a safe working environment.

- Wearing appropriate personal protective equipment.

- Following established safety procedures for grain handling and mixing.

Interview Tips

Preparing thoroughly for a Grain Mixer interview can significantly increase your chances of success. Here are some tips to help you ace the interview:

1. Research the Company and Role

Become familiar with the company’s background, industry standing, and the specific responsibilities of the Grain Mixer role. This will demonstrate your interest and enthusiasm.

- Visit the company’s website and social media pages.

- Read industry news and articles.

2. Highlight Relevant Experience and Skills

Emphasize your experience in grain handling, mixing, and quality control. Quantify your accomplishments whenever possible to showcase your impact.

- Use specific examples to demonstrate your ability to mix and blend grains accurately.

- Highlight your knowledge of grain quality standards.

3. Demonstrate Safety Awareness

Grain mixing involves working with heavy equipment and hazardous materials. Emphasize your commitment to safety by highlighting your experience with personal protective equipment and adherence to safety protocols.

- Describe your understanding of grain handling hazards.

- Explain your experience in following safety guidelines.

4. Show Enthusiasm and Willingness to Learn

Express your passion for the agricultural industry and your eagerness to contribute to the team. Demonstrate your willingness to learn new techniques and technologies.

- Convey your interest in the company’s products and services.

- Ask questions about the company’s vision and growth plans.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Grain Mixer interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!