Feeling lost in a sea of interview questions? Landed that dream interview for Granulator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Granulator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

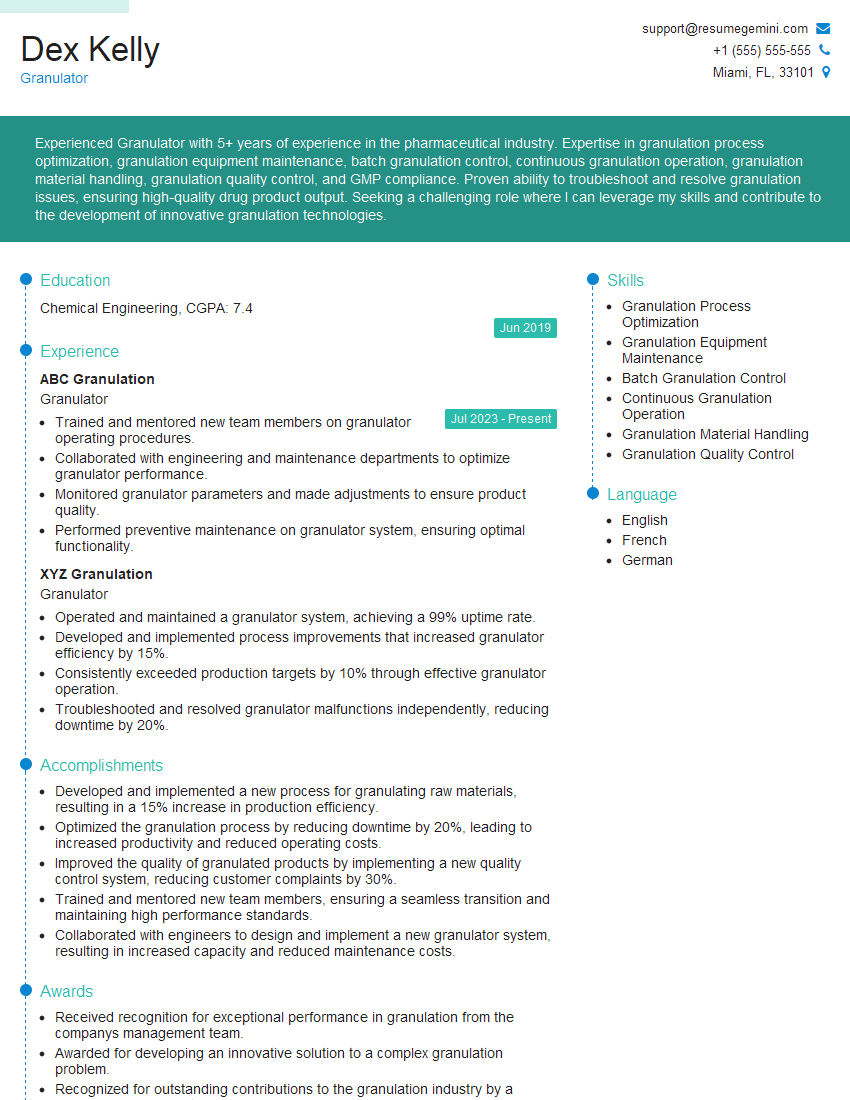

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Granulator

1. What is the role of a granulator in the pharmaceutical industry?

- Granulators are used to reduce the size of pharmaceutical materials into smaller particles.

- This process is essential for various pharmaceutical manufacturing processes, including tableting, capsule filling, and powder blending.

- Granulators help improve the flowability, uniformity, and compressibility of pharmaceutical materials.

2. Describe the wet granulation process and its advantages and disadvantages.

Wet granulation process

- Involves adding a liquid binder to the powder material.

- The mixture is then agitated to form granules.

- The granules are then dried and screened to achieve the desired particle size.

Advantages

- Produces granules with high strength and low friability.

- Can be used to granulate materials with poor flowability.

- Allows for the incorporation of excipients to enhance granule properties.

Disadvantages

- Requires additional drying step, which can be time-consuming and energy-intensive.

- Can be sensitive to moisture and temperature variations.

- May not be suitable for moisture-sensitive materials.

3. Explain the principle of fluid bed granulation and discuss its applications.

Principle of fluid bed granulation

- Powder material is suspended in a stream of hot air.

- A binder solution is sprayed onto the powder particles, causing them to agglomerate and form granules.

- The granules are dried and cooled within the fluid bed.

Applications

- Production of granules with controlled particle size and narrow size distribution.

- Granulation of moisture-sensitive materials.

- Coating of particles with active ingredients or excipients.

4. What are the critical process parameters to consider when operating a granulator?

- Binder solution composition and concentration

- Agitation speed and time

- Drying temperature and time

- Screen mesh size

- Moisture content of the granules

- Particle size distribution

5. Describe the different types of granulators used in the pharmaceutical industry.

- High-shear granulators

- Low-shear granulators

- Fluid bed granulators

- Extrusion granulators

- Roller compactors

6. How do you troubleshoot common granulation problems, such as poor granule formation or excessive dust generation?

Poor granule formation

- Adjust binder solution composition or concentration.

- Increase agitation speed or time.

- Change the screen mesh size.

Excessive dust generation

- Reduce agitation speed or time.

- Increase moisture content of the granules.

- Optimize the drying process.

7. Discuss the importance of granulation in tablet manufacturing.

- Improves the flowability and uniformity of the powder blend.

- Increases the compressibility of the powder, resulting in tablets with higher crushing strength.

- Reduces the risk of capping and lamination during tablet compression.

- Allows for the incorporation of active ingredients and excipients into the tablet.

8. What are the regulatory considerations for granulation in the pharmaceutical industry?

- Granulation processes must be validated to ensure consistent product quality.

- Granulators and other equipment used in granulation should be regularly calibrated and maintained.

- Granulation parameters should be documented and controlled to meet regulatory requirements.

- Granules should be tested for various quality attributes, such as particle size distribution, moisture content, and flowability.

9. Describe the latest advancements in granulation technology.

- Continuous granulation processes

- Use of novel binders and excipients

- In-line monitoring and control systems

- Granulation for personalized medicine and drug delivery systems

10. How do you stay updated with the latest developments in granulation technology?

- Attend industry conferences and workshops.

- Read scientific journals and publications.

- Network with colleagues and experts in the field.

- Participate in research and development projects.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Granulator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Granulator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Granulator is responsible for operating and maintaining granulation equipment used in the manufacturing process, ensuring the production of high-quality granules. Key job responsibilities include:

1. Granulation Process Management

Ensuring the accuracy and efficiency of the granulation process and related equipment by following established protocols. Conducting necessary adjustments to achieve desired granule size, moisture content, and other specifications. Monitoring process parameters such as temperature, pressure, and flow rates to ensure smooth operation.

2. Equipment Operation and Maintenance

Operating and maintaining granulation machinery, including feeders, mixers, granulators, and dryers. Performing regular inspections and preventive maintenance to ensure optimal equipment performance, minimizing downtime and maximizing productivity. Troubleshooting and resolving operational issues promptly to maintain efficient production.

3. Quality Control and Assurance

Adhering to quality control procedures by conducting regular inspections and testing of granules to ensure they meet specifications. Monitoring critical process parameters and implementing corrective actions to prevent deviations. Maintaining accurate records of quality control data for documentation and traceability purposes.

4. Health and Safety Compliance

Complying with established health and safety regulations, including proper handling and disposal of hazardous materials. Ensuring a clean and organized work environment, adhering to lockout/tagout procedures, and using personal protective equipment (PPE) as required.

Interview Tips

1. Research the Company and Position

Demonstrate your genuine interest in the company and the specific Granulator role by researching their industry, products, and company culture. Carefully review the job description to identify the most relevant skills and experiences required.

2. Highlight Your Technical Expertise

Emphasize your proficiency in the granulation process, equipment operation, and maintenance. Share specific examples of your technical skills and how you have used them to improve efficiency or resolve problems. Quantify your accomplishments whenever possible.

3. Communication and Teamwork Skills

Showcase your strong communication and teamwork abilities, as Granulators often collaborate with other production staff and quality control personnel. Highlight your experience in effective communication, problem-solving, and conflict resolution.

4. Quality-Focused Mindset

Convey your commitment to quality and attention to detail. Explain how you have implemented quality control measures in your previous roles and the positive impact it had on product quality and customer satisfaction.

5. Continuous Improvement Attitude

Express your interest in continuous improvement and process optimization. Describe your eagerness to learn new techniques and technologies that can enhance granulation efficiency and overall production processes.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Granulator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!