Feeling lost in a sea of interview questions? Landed that dream interview for Grit Blaster but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Grit Blaster interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

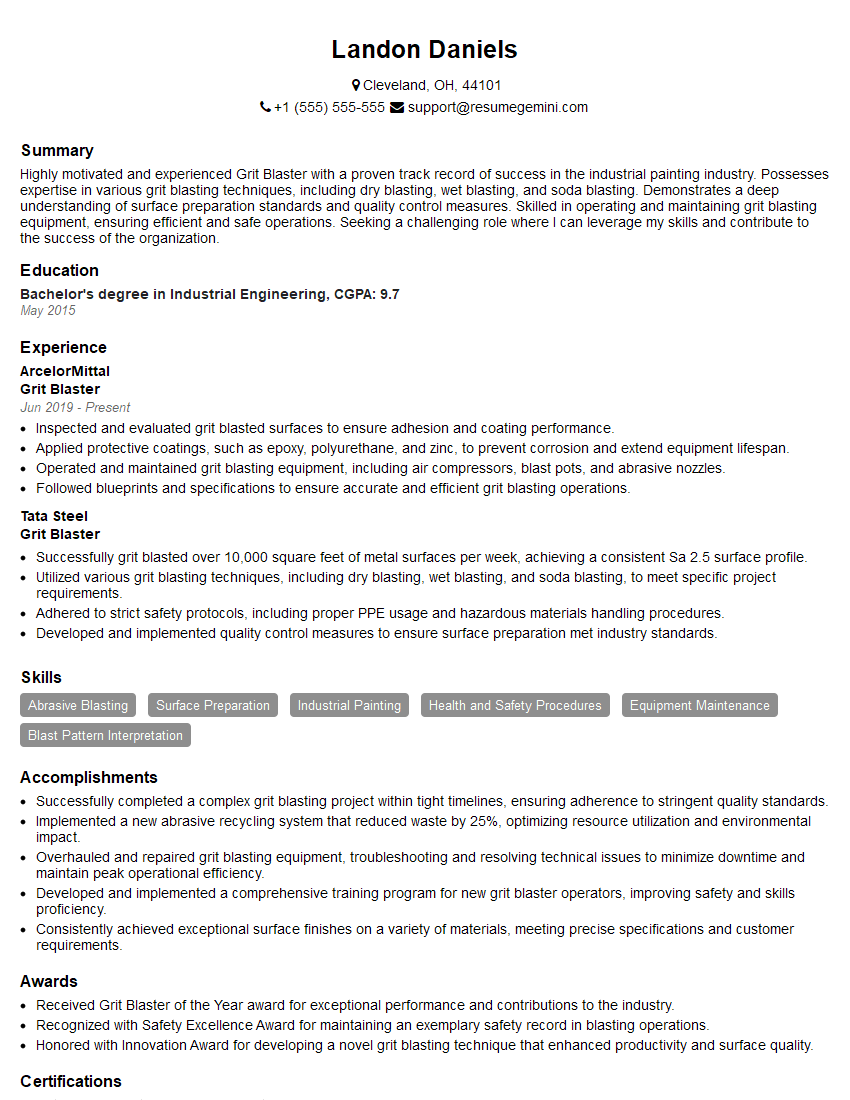

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Grit Blaster

1. What techniques do you use to ensure the safety of yourself and others while performing grit blasting operations?

- Wear appropriate personal protective equipment (PPE), including respirators, eye protection, and gloves.

- Ensure that the work area is well-ventilated and free of dust.

- Use proper blasting equipment and follow all safety protocols.

- Inspect the equipment regularly and make sure it is in good working order.

- Never operate blasting equipment under the influence of drugs or alcohol.

2. How do you determine the correct grit size and pressure settings for different blasting applications?

The correct grit size and pressure settings for different blasting applications depend on the material being blasted, the desired surface finish, and the equipment being used. As a general rule, harder materials require larger grit sizes and higher pressure settings, while softer materials require smaller grit sizes and lower pressure settings.

3. What are the different types of grit blasting equipment, and what are their advantages and disadvantages?

- Suction-feed blasters: These are the most common type of grit blasting equipment. They use a vacuum to draw abrasive material from a hopper and propel it through a nozzle.

- Pressure-feed blasters: These blasters use compressed air to propel abrasive material through a nozzle.

- Wet blasters: These blasters use a mixture of water and abrasive material to clean surfaces.

4. How do you inspect and maintain grit blasting equipment to ensure that it is operating safely and efficiently?

- Inspect the equipment regularly for any signs of wear or damage.

- Clean the equipment after each use to remove any abrasive material or debris.

- Lubricate the equipment regularly according to the manufacturer’s instructions.

- Calibrate the equipment regularly to ensure that it is operating within the specified parameters.

5. What are the different types of abrasive materials used in grit blasting, and what are their advantages and disadvantages?

- Steel grit: Steel grit is a hard and durable abrasive material that is commonly used for removing rust and paint from metal surfaces.

- Aluminum oxide: Aluminum oxide is a medium-hard abrasive material that is commonly used for cleaning and finishing metal surfaces.

- Glass beads: Glass beads are a soft abrasive material that is commonly used for cleaning and finishing delicate surfaces.

6. How do you calculate the coverage rate of a grit blasting operation?

The coverage rate of a grit blasting operation is the number of square feet that can be blasted with a given amount of abrasive material. The coverage rate depends on the grit size, the pressure settings, and the type of surface being blasted.

7. What are the different surface finishes that can be achieved with grit blasting?

- Rough finish: This finish is typically used for removing rust and paint from metal surfaces.

- Smooth finish: This finish is typically used for cleaning and finishing metal surfaces.

- Polished finish: This finish is typically used for giving metal surfaces a mirror-like finish.

8. What are the different applications for grit blasting?

- Removing rust and paint from metal surfaces

- Cleaning and finishing metal surfaces

- Preparing surfaces for coating or painting

- Creating non-slip surfaces

- Removing graffiti

9. What are the safety hazards associated with grit blasting, and how can they be minimized?

- Inhalation of abrasive material: This can be minimized by wearing a respirator.

- Eye injuries: This can be minimized by wearing eye protection.

- Skin injuries: This can be minimized by wearing gloves.

- Noise: This can be minimized by wearing ear protection.

- Silica dust: This can be minimized by using a dust collector.

10. What are the industry standards for grit blasting operations?

- ANSI Z9.4: Safety in Welding, Cutting, and Allied Processes

- AWS C2.23: Recommended Practices for the Preparation of Metal Surfaces for Adhesive Bonding

- SSPC-SP 10: Standard Practice for Abrasive Blast Cleaning of Steel Surfaces

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Grit Blaster.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Grit Blaster‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Grit Blaster is an individual responsible for preparing surfaces by blasting them with abrasive material. This process is often used to remove rust, paint, or other contaminants from metal surfaces.

1. Surface Preparation

Preparing surfaces for blasting involves cleaning them to remove any dirt, grease, or other contaminants. This may involve using detergents, solvents, or other cleaning agents.

- Inspecting surfaces to identify areas that require blasting.

- Removing dirt, grease, or other contaminants from surfaces to ensure optimal adhesion.

2. Blasting Equipment Operation

Operating blasting equipment requires knowledge of the equipment’s functions and safety procedures. Grit Blasters must be able to adjust settings such as pressure, nozzle size, and abrasive flow rate to achieve the desired results.

- Selecting and setting up the appropriate blasting equipment based on the surface and material to be treated.

- Monitoring equipment during operation to ensure proper functioning and make necessary adjustments.

3. Abrasive Selection and Handling

Selecting the correct abrasive material is crucial for effective blasting. Grit Blasters must consider factors such as the surface material, desired finish, and environmental regulations when choosing an abrasive.

- Choosing the appropriate abrasive material based on the surface characteristics and desired outcome.

- Handling and storing abrasive materials safely to prevent health hazards and environmental contamination.

4. Safety Procedures

Blasting is a potentially hazardous process, and Grit Blasters must adhere to strict safety procedures. This includes wearing protective gear, following proper ventilation guidelines, and handling hazardous materials safely.

- Adhering to all safety protocols, including the use of personal protective equipment (PPE), to prevent injuries or exposure to hazardous substances.

- Maintaining a clean and organized work area to minimize tripping hazards and other safety risks.

Interview Tips

Preparing for a Grit Blaster interview requires understanding the key job responsibilities and demonstrating your knowledge and skills. Here are some tips to help you ace the interview:

1. Research the Company and Role

Familiarize yourself with the company’s background, history, and industry standing. Research the specific role to gain insights into the company’s expectations and the scope of the job.

- Visit the company’s website and social media pages.

- Read industry publications and articles.

2. Highlight Relevant Experience and Skills

Emphasize your previous experience in surface preparation, blasting equipment operation, and abrasive selection. Quantify your accomplishments and provide specific examples of your work.

- Use the STAR method (Situation, Task, Action, Result) to describe your experiences.

- Be prepared to discuss your technical skills, such as knowledge of blasting equipment and abrasive materials.

3. Demonstrate Safety Awareness

Highlight your understanding of safety procedures and your commitment to following them. Emphasize your experience with personal protective equipment (PPE) and your knowledge of hazardous materials handling.

- Describe your experience with safety protocols in previous roles.

- Explain how you ensure a safe work environment for yourself and others.

4. Ask Thoughtful Questions

Asking thoughtful questions during the interview shows interest and engagement. Prepare questions that demonstrate your curiosity and understanding of the role and industry.

- Ask about the company’s quality standards and safety protocols.

- Inquire about opportunities for professional development and training.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Grit Blaster interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!