Are you gearing up for a career in Ground Mixer? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Ground Mixer and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

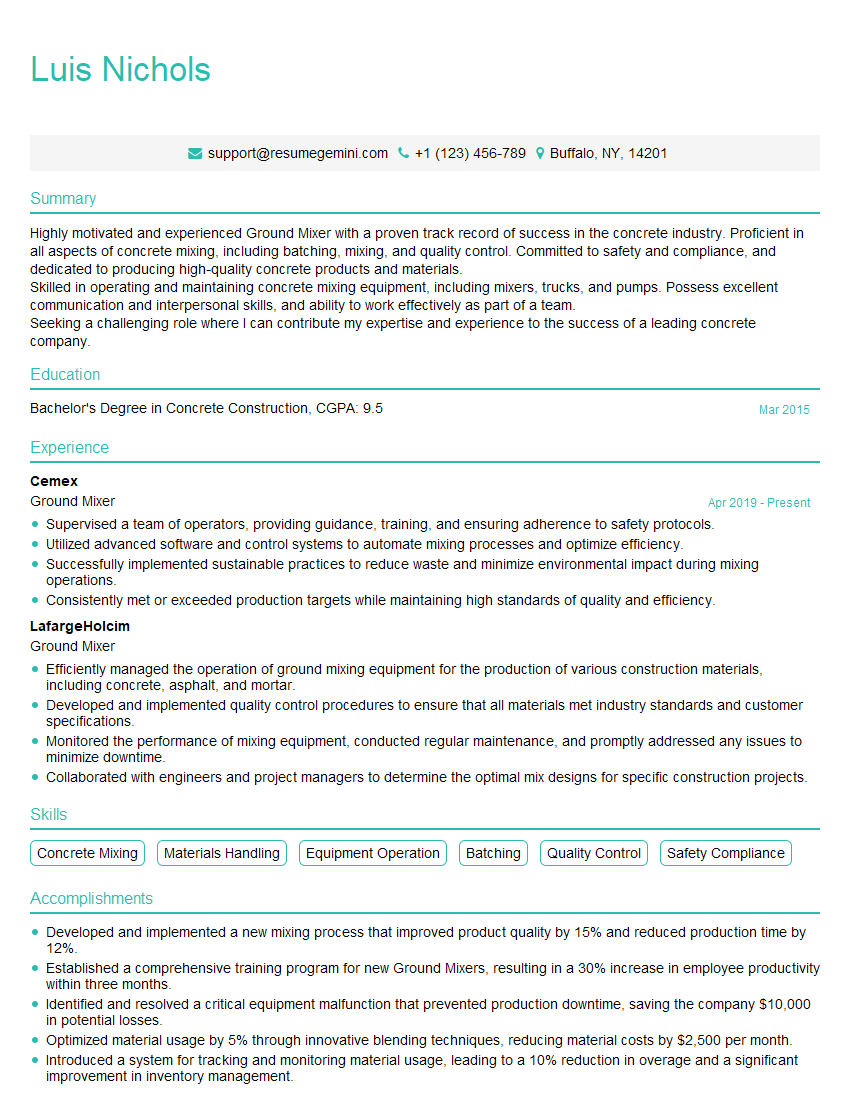

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Ground Mixer

1. What is the role of a Ground Mixer, and what are the key responsibilities?

The Ground Mixer is responsible for preparing and mixing concrete to the correct specifications. Key responsibilities include:

- Loading ingredients into the mixer, including cement, sand, gravel, and water

- Operating the mixer to blend the ingredients thoroughly

- Monitoring the consistency of the concrete and making adjustments as needed

- Pouring the concrete into forms or trucks

- Cleaning and maintaining the mixer

2. Describe the different types of concrete mixers and their applications.

Tilt mixers

- Tilt mixers rotate the mixing drum to blend the ingredients.

- They are commonly used for smaller projects and residential construction.

Truck mixers

- Truck mixers are mounted on trucks and rotate the mixing drum during delivery.

- They are used for large-scale projects and commercial construction.

Transit mixers

- Transit mixers are similar to truck mixers but have a separate engine to power the mixing drum.

- They are used for projects where it is not feasible to use a truck mixer, such as in remote areas or on rough terrain.

3. What are the safety precautions that must be followed when working with concrete?

- Wear proper personal protective equipment (PPE) such as gloves, eye protection, and respirators when handling concrete.

- Keep the work area clean and free of debris.

- Be aware of the potential for slips, trips, and falls.

- Never work alone when mixing or pouring concrete.

- Follow all manufacturer’s instructions for the use of concrete and equipment.

4. How do you determine the correct proportions of ingredients for a specific concrete mix?

The proportions of ingredients for a concrete mix are determined based on the desired strength, durability, and workability of the concrete. Factors to consider include:

- Type of concrete project

- Strength requirements

- Environmental conditions

- Availability of materials

5. What are the different types of admixtures that can be added to concrete, and what are their purposes?

- Air-entraining admixtures introduce tiny air bubbles into the concrete, which helps to reduce the risk of cracking and scaling due to freeze-thaw cycles.

- Water-reducing admixtures help to reduce the amount of water needed in the concrete mix, which can improve strength and durability.

- Accelerating admixtures speed up the setting time of concrete, which can be useful in cold weather or when quick turnaround is required.

- Retarding admixtures slow down the setting time of concrete, which can be useful in hot weather or when more time is needed for placement and finishing.

6. Describe the process of testing concrete for quality control.

- Slump test measures the consistency of fresh concrete.

- Compressive strength test determines the strength of hardened concrete.

- Air content test measures the amount of air in hardened concrete.

- Unit weight test determines the density of hardened concrete.

7. What are the common problems that can occur during concrete mixing and placing, and how can they be resolved?

- Segregation occurs when the different components of concrete separate during mixing or placing. It can be resolved by remixing the concrete or adding a water-reducing admixture.

- Bleeding occurs when water rises to the surface of concrete during placing. It can be resolved by using a concrete mix with a lower water-cement ratio or by adding a bleeding agent.

- Cracking can occur due to a variety of factors, such as shrinkage, temperature changes, or overloading. It can be resolved by using a concrete mix with a higher strength, adding reinforcing steel, or by curing the concrete properly.

8. How do you troubleshoot and repair concrete problems?

- Cracks can be repaired by injecting epoxy or polyurethane into the crack, or by patching the crack with a concrete repair mortar.

- Spalling, which is the breaking away of the surface of concrete, can be repaired by removing the damaged concrete and patching it with a concrete repair mortar.

- Scaling, which is the flaking or peeling of the surface of concrete, can be repaired by removing the damaged concrete and applying a protective coating.

9. What are the benefits of using self-compacting concrete (SCC)?

- SCC flows easily into place, eliminating the need for vibration.

- SCC has a higher strength and durability than conventional concrete.

- SCC is more resistant to segregation and bleeding.

- SCC can be used in difficult-to-reach areas or in congested reinforcement.

10. What are the environmental considerations when working with concrete?

- Concrete production can release greenhouse gases, so it is important to use sustainable practices such as using recycled materials and reducing waste.

- Concrete can also contain hazardous substances, so it is important to dispose of it properly and to avoid spills.

- Concrete can have a negative impact on water quality, so it is important to take measures to prevent runoff and leaching.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Ground Mixer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Ground Mixer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Ground Mixer is responsible for mixing ingredients to create various food products in a commercial setting, such as restaurants, bakeries, or manufacturing plants. They play a vital role in ensuring the quality and consistency of food products.

1. Ingredient Preparation and Handling

Ground Mixers prepare and handle ingredients according to specified recipes. They weigh, measure, and mix ingredients using various equipment, ensuring accuracy and precision.

- Follow recipes and adjust proportions as needed

- Calibrate and maintain equipment

2. Mixing and Blending

Ground Mixers operate mixing machines to combine ingredients thoroughly. They control mixing time, speed, and temperature to achieve desired consistency and texture.

- Use different mixers for specific products, such as dough mixers, blenders, or emulsifiers

- Monitor mixing progress and make adjustments as necessary

3. Quality Control

Ground Mixers ensure the quality of mixed products by checking consistency, taste, and appearance. They follow quality control procedures and specifications.

- Inspect ingredients for freshness and quality

- Conduct sensory evaluations to ensure products meet standards

4. Sanitation and Maintenance

Ground Mixers maintain a clean and sanitary work area. They adhere to hygiene regulations and clean and maintain equipment to prevent contamination and cross-contamination.

- Follow safety protocols and wear appropriate protective gear

- Clean and disinfect work surfaces, utensils, and equipment

Interview Tips

Preparation is key to acing a job interview. Here are some tips to help candidates succeed:

1. Research the Company and Position

Learn about the company’s industry, products or services, and culture. Review the job description carefully to understand the specific requirements and responsibilities.

- Check the company website, social media, and industry publications

- Identify the company’s values and how they align with your own

2. Practice Your Answers

Anticipate common interview questions and prepare concise, relevant answers. Use the STAR method to structure your responses: Situation, Task, Action, Result.

- Example: For a question about teamwork, you could describe a situation where you collaborated with colleagues to solve a problem, outlining your role, actions, and the successful outcome.

- Consider using a mock interview with a friend or mentor to practice delivering your answers confidently.

3. Highlight Relevant Skills and Experience

Emphasize your qualifications that align with the job requirements. Quantify your accomplishments whenever possible, using specific metrics to demonstrate your impact.

- Review the job description and tailor your resume and cover letter to highlight your relevant skills and experience.

- Prepare examples of specific projects or tasks where you excelled in areas critical to the role.

4. Show Your Passion and Enthusiasm

Demonstrate your passion for the food industry and your desire to contribute to the company’s success. Share your knowledge and experience and explain why you are excited about the opportunity.

- Be enthusiastic and positive throughout the interview.

- Ask thoughtful questions about the company and the role to show your engagement.

Next Step:

Now that you’re armed with the knowledge of Ground Mixer interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Ground Mixer positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini