Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Gunite Mixer position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

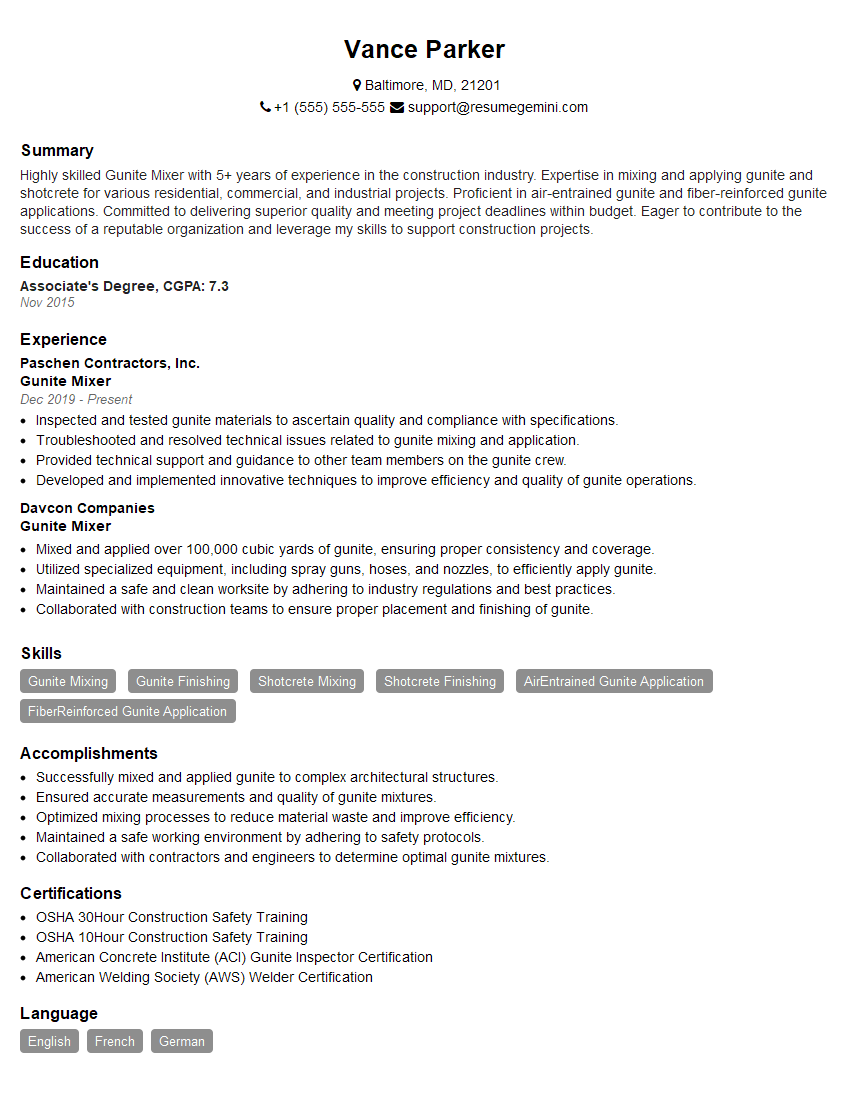

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Gunite Mixer

1. Explain the basic principles of gunite mixing and its importance in construction?

Gunite mixing is a specialized technique used to create a consistent and high-quality mixture of cement, sand, and water. The process involves spraying the mixture onto a surface through a nozzle, resulting in a dense and durable material. Its importance in construction lies in its ability to:

- Form complex shapes and contours that would be difficult to achieve with traditional methods.

- Create a strong and durable structure with high resistance to wear and tear.

- Reduce construction time and costs compared to other methods.

2. Describe the different types of gunite mixers available and their specific applications?

Batch Mixers

- Mix ingredients in batches

- Suitable for small to medium-sized projects

Continuous Mixers

- Continuously feed ingredients into the mixing chamber

- Ideal for large-scale projects

Wet Mixers

- Mix ingredients with water before pumping

- Produce a more fluid mixture

Dry Mixers

- Mix dry ingredients before adding water at the nozzle

- Result in a denser and stronger mixture

3. Discuss the key factors that influence the quality of gunite?

Factors influencing gunite quality include:

- Material Properties: Quality and proportions of cement, sand, and water

- Mixing Process: Proper mixing techniques and equipment to ensure a homogeneous mixture

- Application Technique: Experienced operators and proper spraying methods

- Curing Conditions: Controlled temperature and moisture levels for optimal hydration

- Environmental Factors: Temperature, humidity, and wind conditions can affect the curing process

4. Explain the safety precautions that must be taken when operating a gunite mixer?

Safety precautions for gunite mixing include:

- Protective Gear: Wear appropriate clothing, gloves, respirators, and eye protection

- Proper Handling: Follow manufacturer’s instructions and avoid overfilling the mixer

- Electrical Safety: Ensure proper grounding and avoid contact with electrical components

- Nozzle Control: Keep the nozzle pointed away from operators and avoid blockages

- Emergency Procedures: Have a plan in place for equipment failures or accidents

5. Describe the maintenance and troubleshooting procedures for gunite mixers?

Maintenance and troubleshooting procedures include:

- Regular Cleaning: Remove buildup and debris from the mixer and nozzle

- Component Inspections: Check for worn or damaged parts, such as hoses, valves, and seals

- Lubrication: Grease moving parts according to manufacturer’s specifications

- Troubleshooting: Identify and address common issues, such as clogs, leaks, or pressure fluctuations

- Emergency Repairs: Seek professional assistance for major breakdowns or component failures

6. How do you ensure the accuracy of the gunite mixture proportions?

To ensure accuracy, I follow these steps:

- Calibration: Regularly calibrate the mixer using a scale and measuring devices

- Material Monitoring: Monitor the quality and consistency of materials used

- Proportioning Measurements: Accurately measure and weigh ingredients according to specified ratios

- Mixing Control: Adjust mixing time and speed to achieve the desired consistency

- Testing: Conduct regular tests on the mixed material to verify its properties

7. What techniques can be used to improve the adhesion of gunite to the substrate?

Techniques to improve adhesion include:

- Surface Preparation: Roughen and clean the substrate to increase surface area

- Chemical Bonding Agents: Apply bonding agents to enhance the chemical compatibility between gunite and substrate

- Mechanical Anchoring: Install anchors or pins to provide additional mechanical interlocking

- Curing Methods: Use appropriate curing techniques, such as fogging or wet curing, to promote hydration and bonding

- Texturing: Create a rough surface on the substrate to provide a better grip for the gunite

8. How do you control the thickness and density of the applied gunite layer?

Controlling thickness and density involves:

- Nozzle Distance and Angle: Maintain proper distance and angle between the nozzle and the substrate

- Material Flow Rate: Adjust the flow rate to control the thickness of the layer

- Spray Pattern: Use different spray patterns to achieve varying densities

- Compaction: Use techniques such as tamping or vibrating to compact the gunite and increase its density

- Testing: Regularly measure the thickness and density of the applied layer to ensure compliance with specifications

9. Discuss the different types of finishes that can be achieved with gunite and how they are applied?

Gunite finishes include:

- Smooth Finish: Achieved by using a fine nozzle and applying multiple thin layers

- Texture Finish: Created using a rougher nozzle and spraying from a greater distance

- Exposed Aggregate Finish: Incorporates larger aggregate particles into the mixture for a decorative effect

- Color Finish: Achieved by adding pigments to the mixture

- Stamped Finish: Impressed with patterns or designs using stamps or molds

10. How do you ensure the quality control of gunite during the application process?

Quality control measures for gunite include:

- Material Testing: Verifying the quality of ingredients before mixing

- Mixture Testing: Conducting tests on the mixed material to ensure compliance with specifications

- Visual Inspection: Monitoring the application process and checking for defects

- Destructive Testing: Performing tests on samples of the applied gunite to assess its strength and durability

- Documentation: Maintaining records of all quality control procedures and results

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Gunite Mixer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Gunite Mixer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Gunite Mixer is responsible for operating and maintaining equipment used to mix and spray gunite, a type of concrete used in construction projects. Key responsibilities include:

1. Equipment Operation

Operate and maintain gunite mixing and spraying equipment, including mixers, pumps, and hoses.

- Ensure proper setup and calibration of equipment.

- Monitor equipment performance and make adjustments as needed.

2. Gunite Preparation

Prepare gunite mixtures according to specifications, ensuring proper ratios of ingredients.

- Calculate and weigh materials.

- Add water and mix until desired consistency is achieved.

3. Gunite Spraying

Spray gunite onto surfaces using a spray nozzle, controlling thickness and density.

- Follow safety guidelines and wear appropriate protective gear.

- Inspect sprayed surfaces for defects or irregularities.

4. Equipment Maintenance

Maintain and repair gunite mixing and spraying equipment to ensure optimal performance.

- Clean and lubricate equipment regularly.

- Identify and resolve mechanical issues promptly.

Interview Tips

To ace an interview for a Gunite Mixer position, consider the following tips:

1. Research the Company and Position

Research the company’s projects, culture, and specific requirements for the Gunite Mixer role.

- Visit the company’s website and social media pages.

- Review job descriptions carefully and identify relevant skills and experience.

2. Highlight Relevant Skills and Experience

Emphasize your experience in operating gunite mixing and spraying equipment.

- Provide specific examples of projects where you successfully mixed and sprayed gunite.

- Quantify your results whenever possible, using data to demonstrate your contributions.

3. Demonstrate Safety Awareness

Gunite spraying involves working with hazardous materials and heavy equipment.

- Discuss your knowledge of safety protocols and your commitment to following them.

- Share examples of how you have ensured safety on previous projects.

4. Prepare for Technical Questions

Be prepared to answer technical questions about gunite mixing and spraying.

- Study the different types of gunite mixtures and their applications.

- Understand the proper techniques for spraying gunite onto various surfaces.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Gunite Mixer role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.