Are you gearing up for an interview for a Gunite Nozzle Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Gunite Nozzle Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

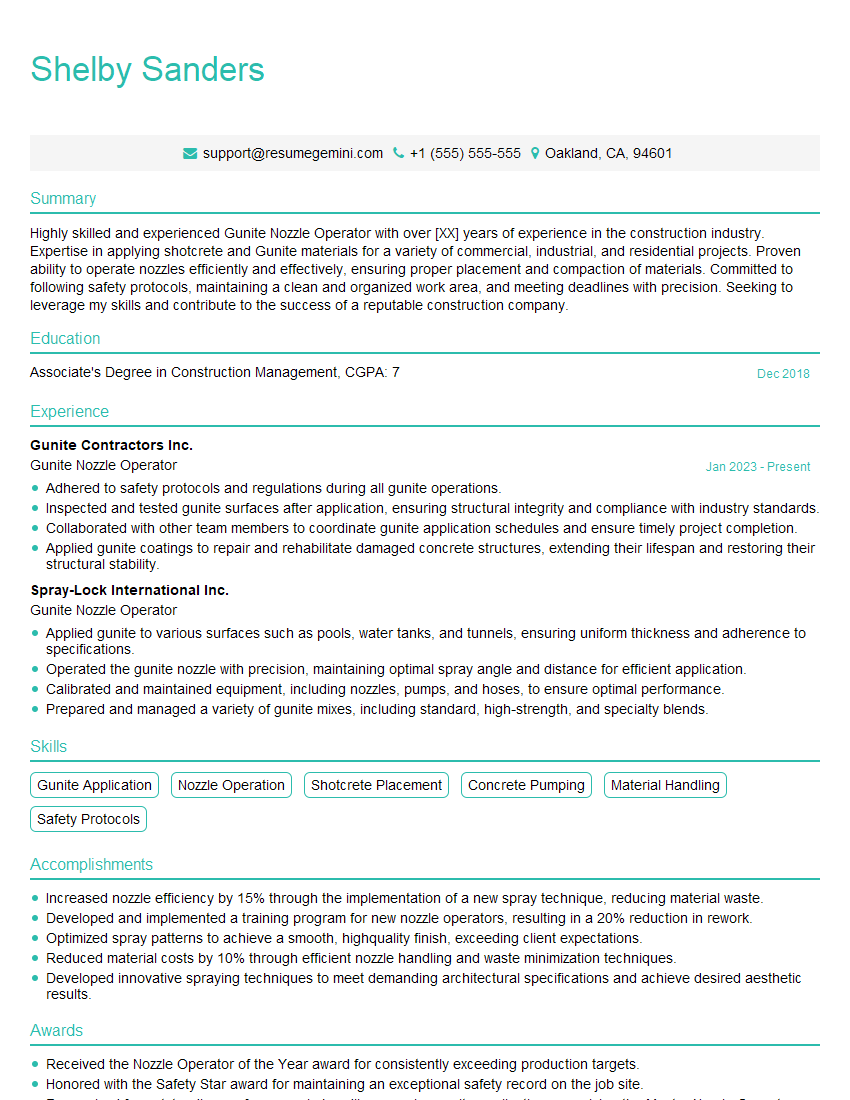

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Gunite Nozzle Operator

1. What are the key responsibilities of a Gunite Nozzle Operator?

As a Gunite Nozzle Operator, my primary responsibilities include:

- Operating and maintaining a gunite machine to apply a concrete mixture to surfaces

- Inspecting and preparing surfaces to ensure proper adhesion of the gunite

- Adjusting nozzles and equipment to achieve the desired spray pattern and thickness

- Monitoring the flow rate, pressure, and consistency of the gunite mixture

- Ensuring the safety of personnel and equipment during the gunite application process

2. How do you ensure the quality and consistency of the gunite application?

Quality Control

- Inspecting the equipment and materials before starting the application process

- Maintaining proper nozzle angles and distances to achieve uniform coverage

- Monitoring the thickness and density of the gunite to meet specifications

- Smoothing and finishing the applied gunite to ensure a seamless and aesthetically pleasing surface

Consistency

- Calibrating the gunite machine to achieve a consistent flow rate and pressure

- Using appropriate nozzle sizes and patterns to match the desired application requirements

- Maintaining a consistent spraying technique and speed to avoid variations in the application

- Regularly checking and adjusting equipment to ensure ongoing optimal performance

3. What safety precautions do you take when operating a Gunite Machine?

- Wearing appropriate personal protective equipment, including a respirator, gloves, and safety glasses

- Establishing and maintaining safe working areas to prevent tripping or falling hazards

- Inspecting equipment and hoses for any damage or leaks before operation

- Following manufacturer’s instructions and guidelines for safe operation and maintenance

- Being aware of the surroundings and potential hazards, such as overhead wires or obstructions

- Communicating effectively with other crew members to ensure coordination and avoid accidents

4. How do you troubleshoot common problems that may arise during gunite application?

- Clogged nozzles: Adjusting nozzle angles, cleaning nozzles with compressed air or water, and replacing worn nozzles

- Improper flow rate: Checking the equipment settings, verifying pressure levels, and inspecting hoses for blockages

- Uneven application: Adjusting nozzle distances, varying spray patterns, and maintaining a consistent spraying technique

- Insufficient bond: Inspecting surface preparation, adjusting mixture proportions, and roughening surfaces to improve adhesion

- Rebound: Reducing spray distance, using smaller nozzle sizes, and applying multiple layers to minimize material loss

5. What techniques do you use to achieve different surface finishes with Gunite?

- Smooth finish: Using a finer nozzle size, maintaining a closer spray distance, and applying multiple layers

- Textured finish: Utilizing a larger nozzle or creating a stippled effect by holding the nozzle further from the surface

- Exposed aggregate finish: Using a larger nozzle and holding it close to the surface to reveal the aggregate in the mixture

- Bush-hammered finish: Chipping the hardened gunite surface with a bush hammer tool to create a textured look

- Architectural finishes: Collaborating with designers to create custom shapes and patterns using stencils or other techniques

6. How do you calculate the amount of gunite needed for a project?

- Measuring the surface area to be applied

- Determining the required thickness of the application

- Calculating the volume of gunite needed using the formula: Volume = Surface Area x Thickness

- Adjusting the calculation based on the specific density of the gunite mixture being used

- Adding a buffer of 5-10% to account for material loss and variations

7. What are the different types of admixtures used in gunite applications and their purposes?

- Accelerators: Speed up the setting time of the gunite, reducing curing time

- Retarders: Delay the setting time, allowing for larger pours and better control

- Water reducers: Enhance workability, reduce water content, and improve strength

- Air-entraining agents: Introduce microscopic air bubbles to increase durability and resistance to freeze-thaw cycles

- Corrosion inhibitors: Protect steel reinforcement from corrosion in harsh environments

8. Explain the process of curing gunite and how you ensure proper curing conditions.

- Moist curing: Keeping the gunite surface wet by spraying, fogging, or covering with burlap or plastic

- Membrane curing: Applying a liquid membrane to the surface to reduce moisture loss

- Temperature control: Maintaining optimal temperature ranges to promote proper hydration and strength development

- Protection from elements: Shielding the gunite surface from direct sunlight, rain, or wind

- Monitoring and adjustment: Regularly checking moisture levels and adjusting curing methods as needed

9. What are the advantages and disadvantages of using Gunite compared to other concrete application methods?

Advantages

- High strength and durability: Provides a dense, impact-resistant surface

- Versatility: Can be applied to various surfaces, shapes, and angles

- Fast application: Allows for rapid construction and reduced labor costs

- Monolithic structure: Creates a seamless, continuous surface without joints or cracks

- Aesthetic appeal: Offers a wide range of finishes and textures for architectural purposes

Disadvantages

- Equipment cost: Requires specialized equipment for application

- Rebound: Some material loss due to overspray and rebound

- Environmental factors: Can be affected by weather conditions, requiring adjustments and precautions

- Skilled labor: Requires trained and experienced operators for optimal results

10. How do you stay updated on the latest developments and best practices in Gunite applications?

- Attending industry conferences and workshops

- Reading technical articles and publications

- Consulting with manufacturers and suppliers

- Participating in online forums and discussions

- Seeking feedback from experienced professionals and mentors

- Continuing education through certification programs or specialized training courses

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Gunite Nozzle Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Gunite Nozzle Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Gunite Nozzle Operator is responsible for managing and controlling the spray head of a gunite machine, which applies a cement-based coating to various surfaces in construction projects.

1. Operating Equipment

Operate and maintain gunite equipment, including the spray head, nozzle, hoses, and compressor.

- Calibrate and adjust the spray head to ensure optimal application thickness and consistency.

- Monitor equipment performance and identify any potential issues or malfunctions.

2. Preparing Surfaces

Prepare surfaces for gunite application by cleaning, roughening, and applying bonding agents.

- Inspect surfaces to determine required preparation and ensure proper adhesion of the gunite coating.

- Use hand tools and equipment to remove dirt, debris, and loose materials.

3. Applying Gunite

Apply gunite to surfaces using the spray head, maintaining proper nozzle position and distance.

- Control the spray pattern, thickness, and angle to achieve desired coverage and reinforcement.

- Follow specified mix designs and application techniques to ensure structural integrity and durability.

4. Finishing and Curing

Finish and cure applied gunite to achieve the desired surface texture and strength.

- Smooth and texture the gunite surface using trowels, brushes, or floats.

- Monitor curing conditions and apply moisture retention techniques to prevent premature drying and cracking.

Interview Tips

To prepare for a Gunite Nozzle Operator interview, consider the following tips:

1. Research the Company and Industry

Learn about the company’s projects, industry trends, and safety protocols to demonstrate your knowledge and interest.

- Visit the company’s website and social media pages.

- Read industry publications and attend webinars.

2. Highlight Your Experience and Skills

Emphasize your experience operating gunite equipment, preparing surfaces, and applying and finishing gunite.

- Quantify your accomplishments using specific metrics and examples.

- Use action verbs to describe your responsibilities and contributions.

3. Prepare for Technical Questions

Be prepared to answer questions about equipment operation, safety procedures, and gunite application techniques.

- Review gunite equipment specifications and maintenance guidelines.

- Study different types of gunite mixes and their applications.

4. Practice Your Interview Skills

Conduct mock interviews with a friend or family member to improve your communication and presentation skills.

- Use the STAR method (Situation, Task, Action, Result) to answer behavioral questions.

- Practice answering common interview questions, such as “Tell me about yourself” and “Why are you interested in this position?”

Next Step:

Now that you’re armed with the knowledge of Gunite Nozzle Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Gunite Nozzle Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini