Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Hard Rock Miner position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

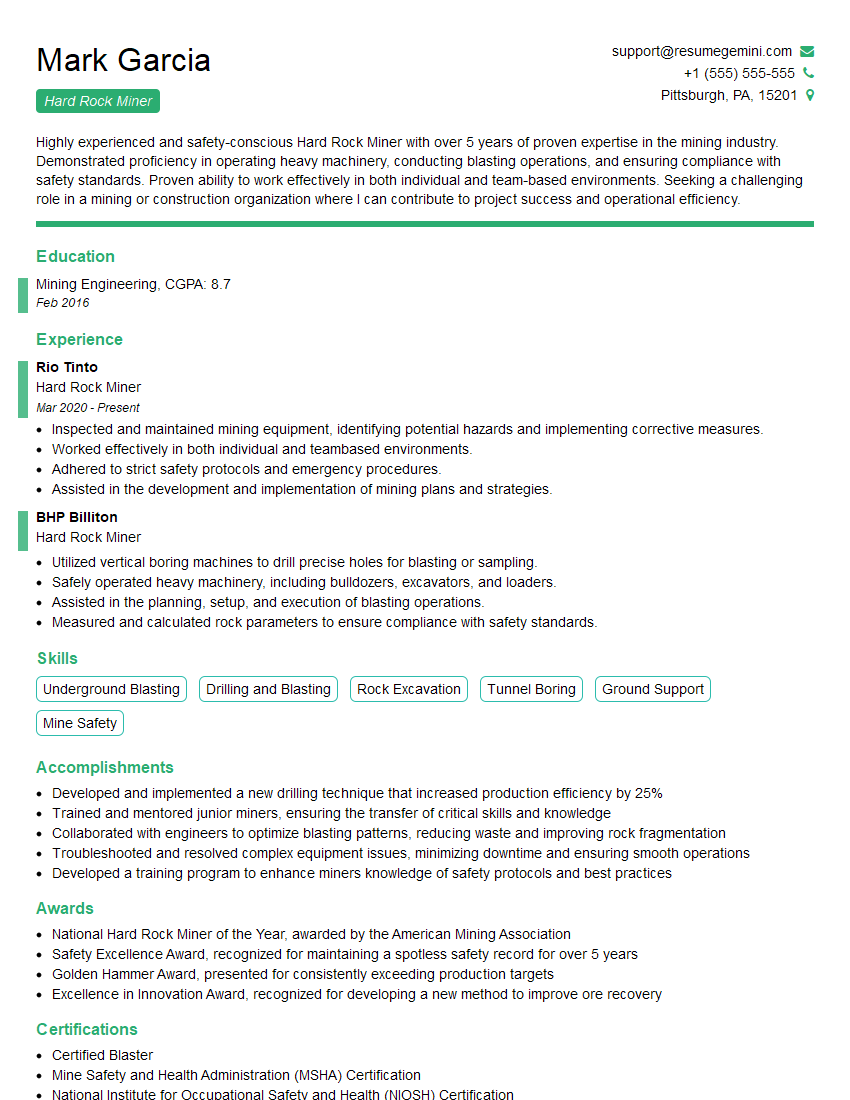

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Hard Rock Miner

1. How do you determine the optimal drilling pattern for a given rock formation?

When determining the optimal drilling pattern for a given rock formation, several factors need to be considered:

- Rock properties: The hardness, abrasiveness, and fracturing characteristics of the rock formation will influence the choice of drilling pattern.

- Drilling equipment: The type of drilling rig, drill bit, and drilling parameters (such as speed and feed rate) will also affect the drilling pattern.

- Desired results: The purpose of the drilling (e.g., exploration, blasting, or well construction) will influence the drilling pattern.

2. What are the different types of drilling fluids and when should each type be used?

Water-based drilling fluids

- Used in soft to medium-hard formations

- Advantages: low cost, readily available, environmentally friendly

- Disadvantages: limited hole stability, can cause formation damage

Oil-based drilling fluids

- Used in hard formations, high-temperature environments, or where hole stability is a concern

- Advantages: excellent hole stability, lubricates drill bit, reduces corrosion

- Disadvantages: higher cost, more difficult to dispose of, can be toxic

Synthetic-based drilling fluids

- Used in a wide range of formations, offering a balance of properties between water-based and oil-based fluids

- Advantages: good hole stability, reduces formation damage, environmentally friendly

- Disadvantages: higher cost than water-based fluids

3. How do you ensure the safety of personnel and equipment during drilling operations?

Ensuring safety during drilling operations involves implementing a comprehensive safety management system that includes:

- Hazard identification and risk assessment: Identifying potential hazards and assessing their risks.

- Safe work procedures: Establishing clear and detailed instructions for all drilling operations.

- Training and competency: Providing adequate training and ensuring that personnel are competent in their roles.

- Personal protective equipment: Requiring the use of appropriate PPE, such as hard hats, gloves, and safety glasses.

- Emergency response plans: Developing and practicing emergency response plans to handle potential incidents.

4. How do you determine the appropriate drilling parameters for a given drilling operation?

Determining the appropriate drilling parameters (such as speed, feed rate, and weight on bit) depends on several factors:

- Rock properties: The hardness, abrasiveness, and fracturing characteristics of the rock formation.

- Drilling equipment: The type of drilling rig, drill bit, and drilling fluids being used.

- Desired results: The purpose of the drilling (e.g., exploration, blasting, or well construction).

- Real-time monitoring: Monitoring drilling parameters and making adjustments as needed based on downhole conditions.

5. What are the common problems encountered in hard rock mining and how do you mitigate them?

Ground control issues:

- Rockfalls and cave-ins: Implementing ground support systems (e.g., rock bolts, shotcrete) to stabilize the rock mass.

- Subsidence: Monitoring ground movement and implementing measures to minimize surface subsidence.

Drilling challenges:

- Hard and abrasive formations: Using specialized drill bits and drilling fluids to improve drilling efficiency.

- Drill bit wear: Optimizing drilling parameters and using wear-resistant drill bits to extend bit life.

6. How do you optimize blasting operations to maximize rock fragmentation and minimize damage to surrounding areas?

Blast design optimization:

- Hole spacing and burden: Determining the optimal hole spacing and burden to achieve desired fragmentation.

- Explosive selection and loading: Choosing the appropriate explosive type and quantity to maximize rock breakage.

- Delay timing: Sequencing the detonation of explosives to control the direction and extent of breakage.

Ground vibration control:

- Pre-blast surveys: Conducting surveys to assess the potential impact of blasting on nearby structures and infrastructure.

- Vibration monitoring: Monitoring ground vibrations during blasting to ensure compliance with regulations and minimize damage.

7. What are the different methods of underground excavation and when should each method be used?

Drill and blast method:

- Used in hard rock formations where drilling and blasting is effective for rock removal.

- Advantages: large excavation volumes, cost-effective.

- Disadvantages: noise, vibrations, potential ground control issues.

Tunnel boring machine (TBM):

- Used in soft to medium-hard rock formations where a continuous excavation process is preferred.

- Advantages: high excavation rates, reduced ground disturbance, safer.

- Disadvantages: higher cost, limited application in hard rock.

8. How do you manage water inflow and outflow in underground mining operations?

Water management strategies:

- Dewatering: Pumping water out of the mine to maintain a dry work environment.

- Drainage systems: Designing and implementing drainage systems to control water flow and prevent flooding.

- Water treatment: Treating mine water to remove contaminants before releasing it into the environment.

Environmental considerations:

- Water conservation: Minimizing water consumption and maximizing water reuse.

- Pollution prevention: Implementing measures to prevent water contamination from mining activities.

9. How do you ensure the stability and safety of underground structures such as tunnels and shafts?

Geotechnical assessment:

- Conducting thorough geological and geotechnical investigations to understand the rock mass characteristics.

- Assessing potential hazards and designing appropriate support systems.

Structural design:

- Designing underground structures to withstand the anticipated loads and stresses.

- Using appropriate materials and construction techniques to ensure structural integrity.

Monitoring and maintenance:

- Implementing monitoring systems to track structural performance and detect any changes or anomalies.

- Performing regular inspections and maintenance to preserve the stability and safety of underground structures.

10. What are the latest advancements in hard rock mining technology and how have they improved safety and efficiency?

Advanced drilling equipment:

- Drill rigs with automated controls and downhole sensors for improved drilling accuracy and efficiency.

- Specialized drill bits designed for hard rock formations, resulting in reduced wear and tear.

Automation and robotics:

- Autonomous drilling systems that reduce the need for manual labor and increase safety.

- Remotely operated vehicles for hazardous tasks, such as inspection and maintenance.

Data analytics and modeling:

- Using data analytics to optimize drilling patterns, blasting designs, and ground support systems.

- Developing predictive models to identify potential hazards and improve risk management.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Hard Rock Miner.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Hard Rock Miner‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Hard Rock Miners are responsible for extracting valuable minerals and rocks from the earth using specialized equipment and techniques.

1. Operate Heavy Machinery

Operate heavy machinery such as drills, bulldozers, and excavators to extract minerals and rocks from the earth.

- Maintain and repair machinery to ensure optimal performance.

- Follow safety protocols to minimize risks and hazards.

2. Identify and Extract Minerals

Identify and extract valuable minerals and rocks using geological knowledge and specialized equipment.

- Analyze rock samples to determine mineral content.

- Use explosives or other techniques to extract minerals from the earth.

3. Transport Minerals

Transport extracted minerals from the mine site to processing facilities using trucks or other means of transportation.

- Ensure minerals are properly loaded and secured for safe transport.

- Follow regulations and guidelines for transporting hazardous materials.

4. Maintain Work Area

Maintain a safe and organized work area by following safety regulations and best practices.

- Inspect equipment regularly and report any issues.

- Clean up work area and dispose of waste materials properly.

Interview Tips

Preparing thoroughly for a Hard Rock Miner interview can significantly increase your chances of success.

1. Research the Company and Position

Learn about the company’s history, values, and current projects to demonstrate your interest and knowledge.

- Visit the company website and read industry publications.

- Connect with current or former employees on LinkedIn.

2. Highlight Relevant Skills

Emphasize your experience operating heavy machinery, identifying and extracting minerals, and maintaining a safe work environment.

- Quantify your accomplishments with specific metrics.

- Provide examples of your problem-solving abilities and attention to detail.

3. Demonstrate Safety Awareness

Hard Rock Mining involves potential hazards, so it’s crucial to convey your understanding of safety protocols and commitment to following them.

- Describe your experience with safety training and certifications.

- Share examples of your proactive approach to identifying and mitigating risks.

4. Prepare for Physical and Technical Questions

Expect questions about your physical fitness, ability to work in demanding conditions, and knowledge of mining equipment and techniques.

- Emphasize your physical strength and endurance.

- Describe your experience with specific equipment and technologies used in mining.

5. Show Enthusiasm and Motivation

Express your passion for mining and eagerness to contribute to the company’s success.

- Explain why you are interested in this specific role and company.

- Share your goals and aspirations for your career in mining.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Hard Rock Miner interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.