Are you gearing up for a career in Head Insulation Board Saw Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Head Insulation Board Saw Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

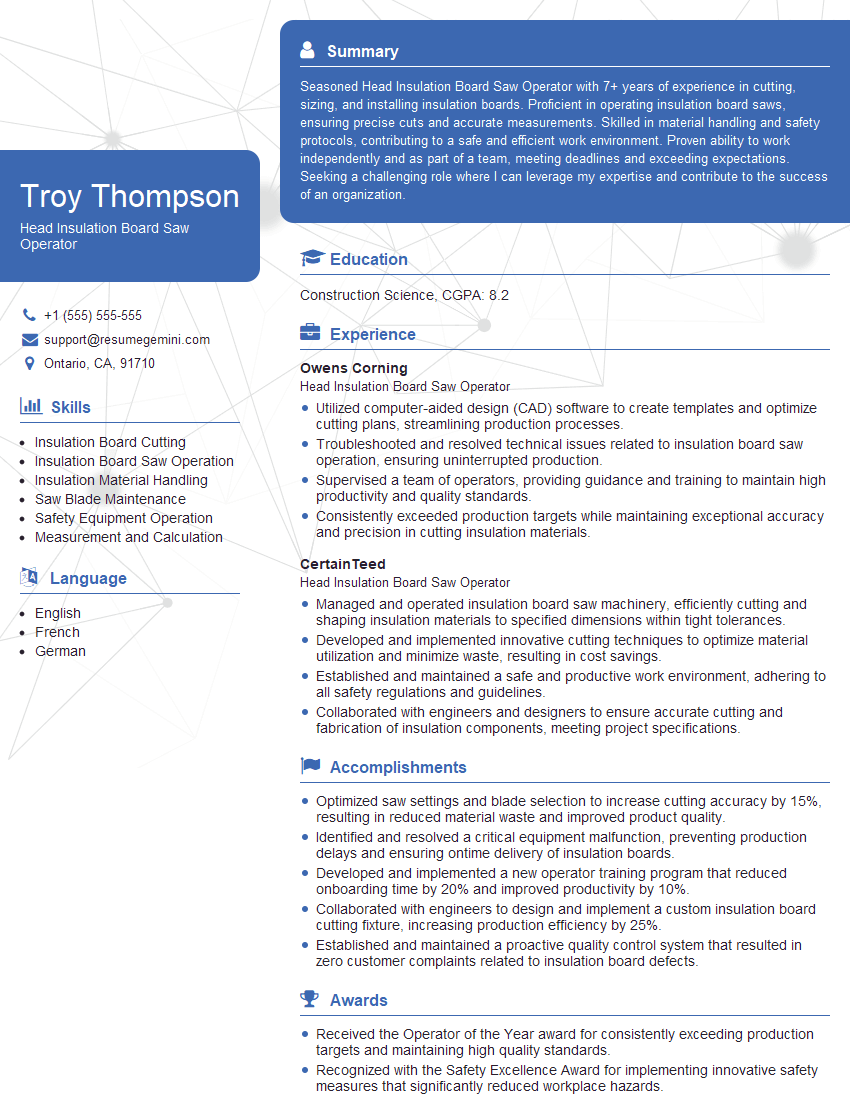

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Head Insulation Board Saw Operator

1. What are the key responsibilities of a Head Insulation Board Saw Operator?

- Operate and maintain insulation board saws to cut and shape insulation boards according to specifications.

- Ensure that the saws are properly calibrated and maintained for optimal performance.

- Inspect incoming insulation boards for defects and ensure that they meet quality standards.

- Load and unload insulation boards onto the saw table and operate the machine to cut the boards to the desired dimensions.

- Ensure that the cut boards meet the specified tolerances and dimensions.

2. Describe the different types of insulation boards and their applications.

Types of insulation boards

- Polystyrene insulation boards

- Polyurethane insulation boards

- Extruded polystyrene insulation boards

- Fibreglass insulation boards

Applications

- Building insulation

- Industrial insulation

- Transportation insulation

- Acoustic insulation

3. What is the importance of proper blade selection for insulation board saws?

- Selecting the correct blade for the type of insulation board being cut ensures clean and precise cuts.

- Appropriate blade selection prevents tearing, chipping, or damage to the insulation board.

- The blade’s sharpness, number of teeth, and tooth geometry affect the cutting efficiency and quality.

4. How do you ensure the accuracy of cuts made with an insulation board saw?

- Proper calibration of the saw’s blade and fence ensures precise cuts.

- Using measuring tapes, rulers, and other measuring tools to verify the dimensions of the cut pieces.

- Checking the alignment of the blade with the saw table and fence regularly.

- Regular maintenance and lubrication of the saw’s components to prevent any play or inaccuracies.

5. What safety precautions should be taken when operating an insulation board saw?

- Wearing appropriate safety gear, including eye protection, ear protection, and gloves.

- Ensuring that the saw is properly grounded and the blade guard is in place.

- Inspecting the saw’s components regularly for any signs of damage or wear.

- Using push sticks or other tools to feed the insulation boards into the saw.

- Keeping the work area clean and free of debris to prevent accidents.

6. How do you troubleshoot common problems encountered with insulation board saws?

- Inspecting the blade for sharpness and wear.

- Checking the alignment of the blade with the saw table and fence.

- Ensuring that the saw is properly lubricated.

- Checking the electrical connections and power supply.

- Consulting the manufacturer’s manual for specific troubleshooting guidance.

7. Describe the different types of insulation board saws and their respective applications.

- Horizontal insulation board saws: Designed for cutting large insulation boards into smaller pieces.

- Vertical insulation board saws: Ideal for cutting insulation boards into strips or specific shapes.

- Portable insulation board saws: Used for on-site cutting of insulation boards in construction or renovation projects.

8. How do you optimize the cutting speed and feed rate of an insulation board saw for different types of boards?

- Adjusting the cutting speed and feed rate based on the thickness, density, and material composition of the insulation board.

- Using higher cutting speeds for softer insulation boards and lower cutting speeds for harder boards.

- Setting the feed rate to ensure a smooth and controlled cut without burning or tearing the insulation board.

9. What are the critical quality control measures implemented for insulation board cutting?

- Verifying the dimensions of the cut pieces to ensure they meet the specified tolerances.

- Inspecting the cut surfaces for any defects, such as tears, chips, or unevenness.

- Checking the insulation board’s thickness and density to ensure they meet the required specifications.

10. How do you handle and store insulation boards to maintain their quality and prevent damage?

- Storing insulation boards in a dry and well-ventilated area to prevent moisture absorption.

- Handling insulation boards carefully to avoid bending or breaking them.

- Stacking insulation boards flat and evenly to prevent warping or damage.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Head Insulation Board Saw Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Head Insulation Board Saw Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Head Insulation Board Saw Operator plays a vital role in the production of insulation board by managing and operating saw machines to cut and shape insulation material.

1. Setup and Operation

Ensures that saw machines are properly set up and calibrated according to job specifications.

- Selects and installs appropriate saw blades and cutting tools.

- Adjusts machine settings for cutting speed, depth, and angle.

- Monitors the operation of machines closely to ensure smooth and efficient production.

2. Quality Control

Maintains high standards of product quality by inspecting cut insulation boards for accuracy and defects.

- Ensures that boards meet specified dimensions and shape.

- Identifies and rejects any defective boards to prevent further processing.

- Calibrates and maintains measuring equipment used for quality control.

3. Safety and Maintenance

Promotes a safe and clean work environment for team members and maintains the equipment in good condition.

- Adheres to all safety regulations and guidelines.

- Identifies and reports potential hazards to the supervisor.

- Performs routine maintenance and cleaning tasks as needed.

4. Training and Development

Contributes to the development of team members by providing guidance and training.

- Shares knowledge and expertise to enhance team performance.

- Assists in identifying training needs for team members.

- Provides support and feedback to junior operators.

Interview Tips

Preparing thoroughly for an interview can significantly increase your chances of success. Here are some tips to help you ace your interview for the Head Insulation Board Saw Operator position:

1. Research

Extensive research about the company, the industry, and the specific role can give you an edge during the interview.

- Visit the company’s website and social media platforms to learn about their mission, values, and recent developments.

- Explore industry publications and news articles to demonstrate your knowledge of the insulation board manufacturing sector.

- Thoroughly review the job description to understand the key responsibilities and qualifications required for the position.

2. Highlight Relevant Experience

Focus on showcasing your relevant skills and experiences during the interview.

- Emphasize your experience in operating saw machines, particularly in the insulation board production industry.

- Provide specific examples of how you ensured product quality and safety in previous roles.

- Highlight your ability to work independently, as well as your teamworking and communication skills.

3. Prepare for Common Interview Questions

Anticipating common interview questions and preparing thoughtful answers can boost your confidence and improve your chances of success.

- Practice answering questions about your experience, qualifications, and motivation for applying for the role.

- Consider how you would respond to questions about your problem-solving abilities, attention to detail, and safety awareness.

- Prepare questions to ask the interviewer, demonstrating your interest in the position and the company.

4. Professionalism and Appearance

Professionalism and a positive attitude can make a lasting impression on the interviewer.

- Dress appropriately for the interview, adhering to business casual attire.

- Arrive punctually for your interview and greet the interviewer with a firm handshake and a smile.

- Maintain eye contact during the interview and actively listen to the interviewer’s questions.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Head Insulation Board Saw Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.