Are you gearing up for a career in Horizontal Boring Mill Set-Up Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Horizontal Boring Mill Set-Up Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

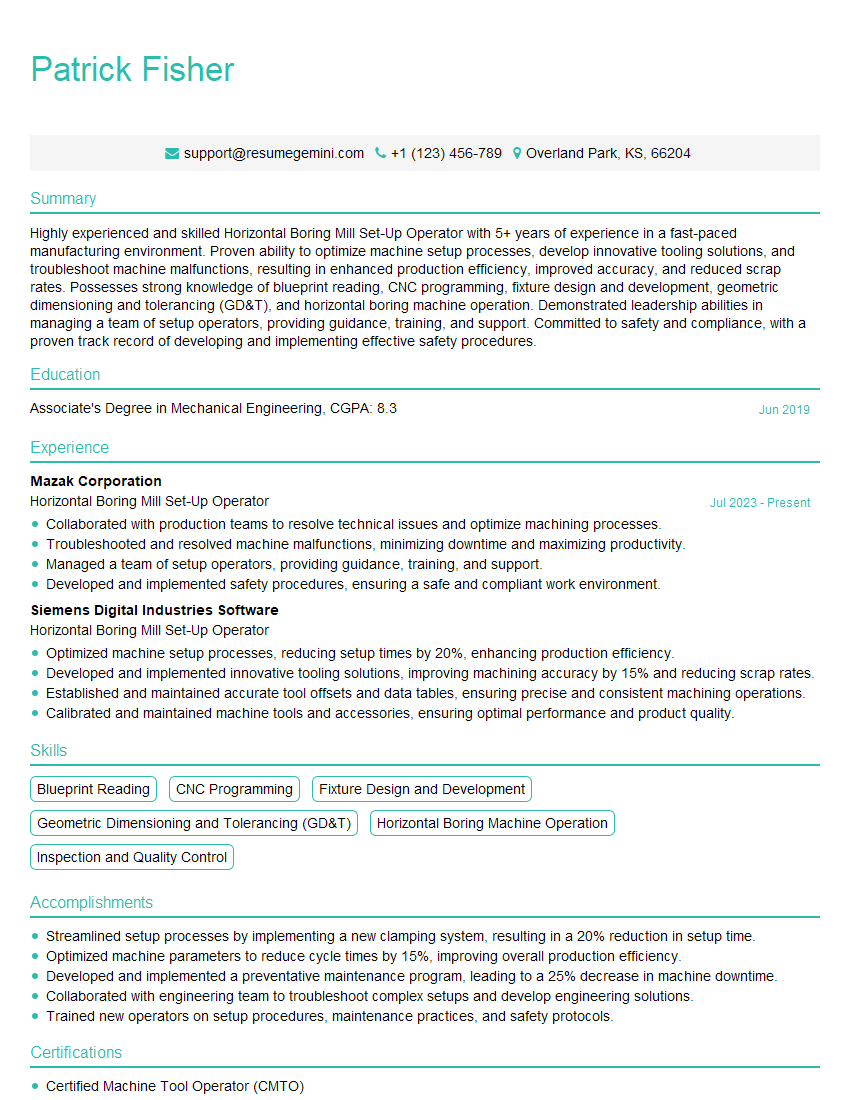

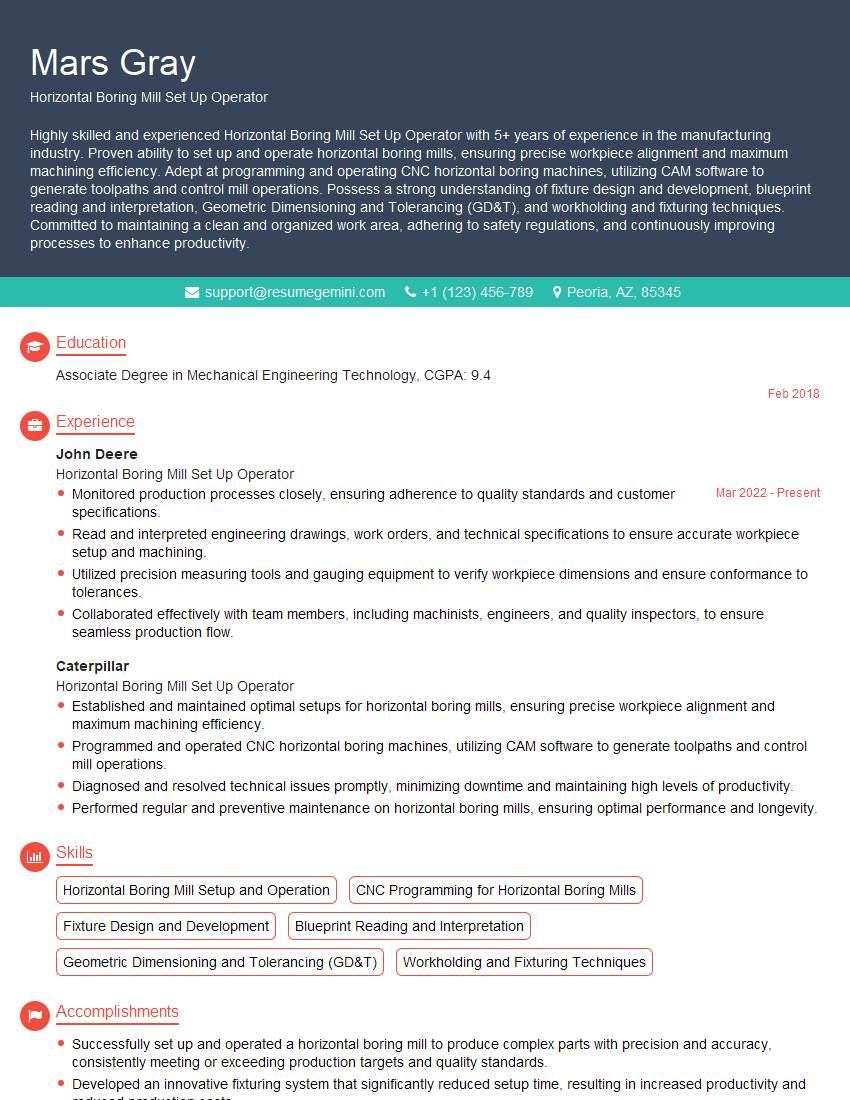

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Horizontal Boring Mill Set-Up Operator

1. Explain the steps involved in setting up a horizontal boring mill for a complex workpiece?

- Analyze the workpiece drawings and identify the required machining operations.

- Select and install the appropriate tooling, including boring bars, cutters, and inserts.

- Calculate and set the spindle speed, feed rate, and depth of cut based on the workpiece material and desired finish.

- Secure the workpiece in the fixture and align it accurately with the spindle axis.

- Set up the coordinate system and zero the machine axes.

- Verify the setup and run a test program to ensure accuracy and precision.

2. Describe the different types of tooling used on a horizontal boring mill and their applications?

Boring Tools

- Single-point boring bars: For precision boring of holes to tight tolerances.

- Multi-point boring heads: For faster boring of larger holes or holes with complex geometries.

Cutting Tools

- End mills: For milling flat surfaces, slots, and pockets.

- Face mills: For milling large flat surfaces.

- Shoulder cutters: For creating steps and shoulders.

3. How do you ensure the accuracy and precision of machined parts on a horizontal boring mill?

- Use high-quality tooling and maintain it regularly.

- Set up the machine accurately and zero the axes precisely.

- Control the cutting parameters (speed, feed, depth of cut) to minimize deflection and vibration.

- Use fixtures and clamps to securely hold the workpiece in place.

- Inspect the machined parts regularly using appropriate measuring instruments.

4. Explain the importance of proper lubrication and coolant usage on a horizontal boring mill?

- Reduces friction and wear on cutting tools and machine components.

- Cools the cutting zone to prevent overheating and premature tool failure.

- Washes away chips and debris to improve surface finish and tool life.

- Protects the machine from corrosion and rust.

5. Describe the safety precautions to take when operating a horizontal boring mill?

- Wear appropriate safety gear (glasses, gloves, hearing protection).

- Keep work area clean and free of obstructions.

- Avoid loose clothing and jewelry that can get caught in the machine.

- Be aware of the moving parts and keep hands clear of the cutting zone.

- Use proper lifting techniques and avoid overexertion.

6. Explain the role of CNC (Computer Numerical Control) in horizontal boring mill operation?

- Automates the machining process based on a computer program.

- Provides faster and more precise machining than manual operation.

- Reduces setup time and improves repeatability.

- Allows for complex machining operations and contouring.

- Enhances safety by reducing human error.

7. Describe the types of materials that can be machined on a horizontal boring mill?

- Metals: Steel, iron, aluminum, titanium, etc.

- Plastics: Acrylic, polycarbonate, nylon, etc.

- Composites: Fiberglass, carbon fiber, etc.

- Wood:

8. Explain the advantages and disadvantages of using a horizontal boring mill?

Advantages

- High precision and accuracy

- Can perform complex machining operations

- Suitable for large and heavy workpieces

- Automates the machining process

Disadvantages

- High cost of equipment and tooling

- Requires skilled operators

- Can be slow for certain operations

- Not suitable for machining small or intricate parts

9. Describe the maintenance procedures for a horizontal boring mill?

- Regular cleaning and lubrication

- Inspection and replacement of worn or damaged parts

- Calibration and adjustment of spindles and axes

- Software updates and troubleshooting

- Preventive maintenance to prevent breakdowns

10. Explain the troubleshooting techniques for common problems encountered in horizontal boring mill operation?

- Poor surface finish: Check tool wear, cutting parameters, and workpiece clamping.

- Dimensional errors: Verify machine setup, tooling accuracy, and workpiece alignment.

- Machine vibration: Inspect bearings, spindles, and couplings for damage or wear.

- CNC errors: Refer to the machine manual and troubleshoot the specific error code.

- Tool breakage: Check tool selection, cutting parameters, and workpiece material.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Horizontal Boring Mill Set-Up Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Horizontal Boring Mill Set-Up Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Horizontal Boring Mill Set-Up Operators are highly skilled individuals who are responsible for overseeing the setup, maintenance, and operation of horizontal boring machines in a manufacturing environment.1. Machine Set-Up

- Establish and maintain machine parameters, including feeds, speeds, and tooling.

- Secure and align work-pieces to precision specifications.

2. Tooling and Adjustments

- Select and install appropriate tooling and cutting instruments.

- Make precision adjustments to tooling and machine settings to achieve optimal performance.

3. Operation and Monitoring

- Operate the machine safely and efficiently, ensuring smooth and precise operation.

- Monitor equipment performance and make necessary adjustments to maintain quality and productivity.

4. Inspection and Quality Control

- Inspect work-pieces to verify accuracy and compliance with specifications.

- Interpret drawings and technical data to ensure correct setup and operation.

Interview Tips

To ace an interview for a Horizontal Boring Mill Set-Up Operator position, here are some essential tips:1. Research the Company and Role

– Familiarize yourself with the company’s industry, size, and products/services. – Thoroughly review the job description to identify key responsibilities and requirements.2. Highlight Your Skills and Experience

– Emphasize your expertise in setting up, operating, and maintaining horizontal boring machines. – Provide specific examples of your accomplishments in precision machining and quality control.3. Be Prepared to Discuss Machine Knowledge

– Demonstrate your understanding of the principles of horizontal boring, including setups, tooling selection, and machine optimization. – Explain how you use your knowledge to achieve high-quality, efficient production.4. Show Your Passion for Precision

– Explain your attention to detail and commitment to achieving the highest levels of accuracy. – Share examples of how you have consistently exceeded quality expectations in previous roles.5. Ask Thoughtful Questions

– Engage the interviewer by asking questions that show your interest in the position and the company. – Inquiries about the company’s production processes, safety procedures, or training opportunities can demonstrate your enthusiasm.6. Be Confident and Professional

– Maintain a positive and professional demeanor throughout the interview. – Dress appropriately, arrive on time, and show respect for the interviewer and the company.Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Horizontal Boring Mill Set-Up Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!