Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Hot Mix Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Hot Mix Operator so you can tailor your answers to impress potential employers.

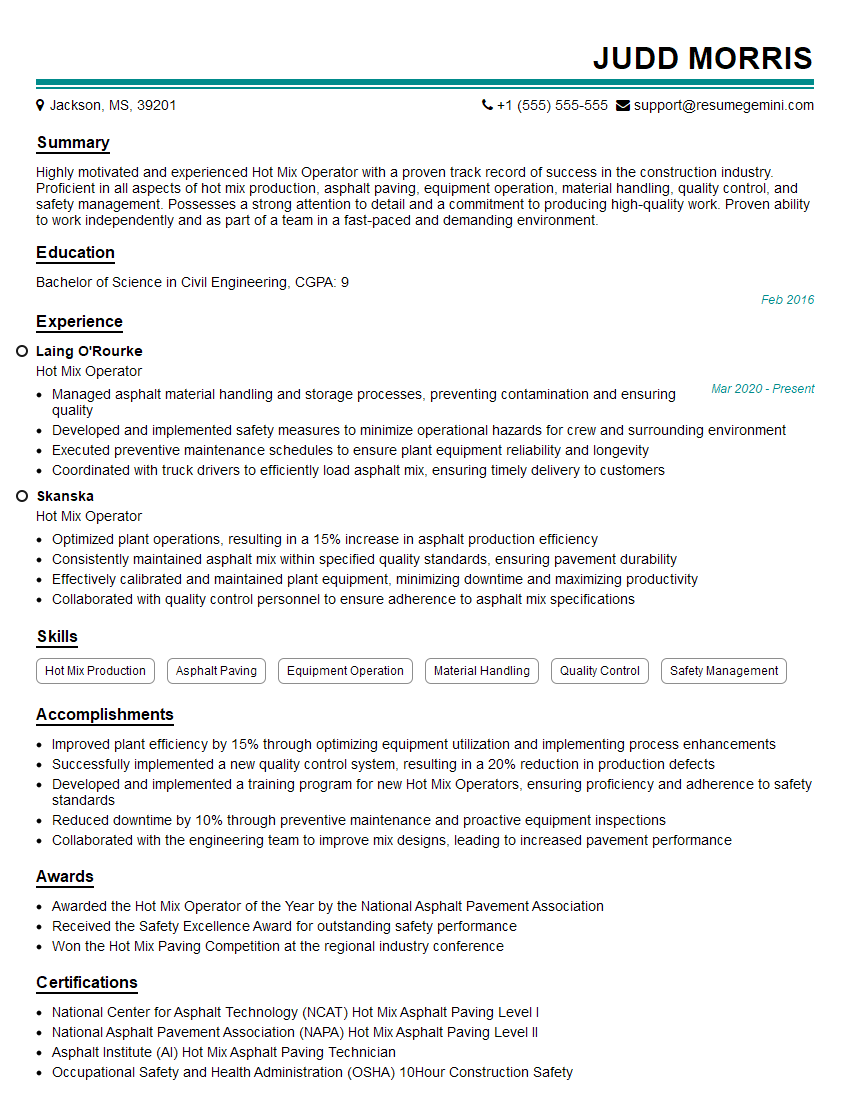

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Hot Mix Operator

1. Describe the key responsibilities of a Hot Mix Operator?

As a Hot Mix Operator, I would be responsible for the following key duties:

- Operate and maintain hot mix asphalt equipment, including mixers, pavers, and rollers.

- Monitor and adjust the temperature and consistency of the asphalt mix to ensure it meets specifications.

- Load and unload asphalt materials, such as sand, gravel, and bitumen.

- Perform routine maintenance and repairs on equipment.

- Adhere to safety regulations and guidelines.

2. Explain the different types of hot mix asphalt and their applications?

Dense-Graded Asphalt

- Most common type of asphalt.

- Used for roads, highways, and parking lots.

- Provides a smooth and durable surface.

Open-Graded Asphalt

- Contains more air voids than dense-graded asphalt.

- Used for airport runways and other areas where drainage is important.

- Provides good skid resistance and reduces noise.

3. How do you ensure the quality of the asphalt mix?

I ensure the quality of the asphalt mix by:

- Following established mix designs and specifications.

- Calibrating and maintaining equipment regularly.

- Monitoring the temperature and consistency of the mix throughout the production process.

- Performing quality control tests, such as density and gradation tests.

- Making adjustments to the mix as needed based on test results.

4. What safety precautions should be taken when working with hot mix asphalt?

When working with hot mix asphalt, I take the following safety precautions:

- Wear appropriate personal protective equipment, including gloves, safety glasses, and a hard hat.

- Be aware of the location of fire extinguishers and other emergency equipment.

- Stay clear of moving equipment and hot surfaces.

- Use proper lifting techniques to avoid injuries.

- Follow all established safety protocols and procedures.

5. Describe the process of paving a road with hot mix asphalt?

The process of paving a road with hot mix asphalt typically involves the following steps:

- Preparing the subgrade by grading and compacting it.

- Laying down a tack coat to improve adhesion between the subgrade and asphalt.

- Spreading the hot mix asphalt evenly over the prepared surface.

- Compacting the asphalt using a roller to achieve the desired density and smoothness.

- Allowing the asphalt to cool and cure before opening the road to traffic.

6. How do you troubleshoot common problems that may occur during the asphalt paving process?

Common problems that may occur during the asphalt paving process include:

Segregation

- Cause: Improper mixing or handling of the asphalt mix.

- Solution: Adjust equipment settings or mix design.

Rutting

- Cause: Excessive traffic load or weak subgrade.

- Solution: Reinforce the subgrade or use a stiffer asphalt mix.

7. What is the importance of proper compaction in asphalt paving?

Proper compaction in asphalt paving is essential because it:

- Increases the density and strength of the asphalt.

- Reduces the risk of cracking and deformation.

- Improves the durability and longevity of the pavement.

- Ensures a smooth and safe driving surface.

8. How do you maintain and calibrate asphalt paving equipment?

To maintain and calibrate asphalt paving equipment, I perform the following tasks:

- Regularly inspect and clean equipment.

- Lubricate moving parts and replace worn components.

- Calibrate sensors and gauges to ensure accuracy.

- Follow manufacturer’s maintenance and calibration schedules.

- Keep a detailed maintenance log for each piece of equipment.

9. Describe your experience with different types of asphalt paving projects?

I have experience with a variety of asphalt paving projects, including:

- Highways and roads.

- Parking lots and driveways.

- Airports and runways.

- Industrial and commercial properties.

I am familiar with the different mix designs and construction techniques required for each type of project.

10. What is your approach to working as part of a team on a large-scale asphalt paving project?

When working on a large-scale asphalt paving project, I believe it is important to:

- Communicate effectively with other team members.

- Follow instructions and adhere to safety protocols.

- Be flexible and adaptable to changing conditions.

- Contribute to the team’s success by sharing knowledge and expertise.

- Maintain a positive and professional attitude.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Hot Mix Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Hot Mix Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Hot Mix Operators play a crucial role in the production of asphalt, a vital material used in road construction and maintenance. Their key responsibilities include:

1. Operating Asphalt Mixing Equipment

Hot Mix Operators are responsible for operating asphalt mixing equipment, including asphalt plants, pavers, and rollers. They ensure that the equipment is functioning properly and that the asphalt is mixed to the correct specifications.

- Calibrating and maintaining mixing equipment

- Monitoring asphalt temperature and consistency

2. Monitoring Production Process

Hot Mix Operators closely monitor the asphalt production process to ensure that it is running smoothly. They adjust equipment settings as needed to maintain the desired quality of the asphalt.

- Inspecting raw materials and finished products

- Troubleshooting equipment malfunctions

3. Loading and Transporting Asphalt

Hot Mix Operators load asphalt into trucks and other vehicles for transportation to construction sites. They ensure that the asphalt is loaded properly to prevent spills or damage.

- Communicating with drivers to coordinate loading and delivery

- Maintaining a clean and organized work area

4. Maintaining Equipment and Facilities

Hot Mix Operators are responsible for maintaining the asphalt mixing equipment and facilities. They perform regular inspections, clean and lubricate equipment, and make minor repairs as needed.

- Following safety protocols and regulations

- Working effectively in a team environment

Interview Tips

To ace an interview for a Hot Mix Operator position, it is essential to prepare thoroughly and demonstrate your skills and experience. Here are some tips to help you succeed:

1. Research the Company and Industry

Research the company you are applying to and the asphalt industry as a whole. This will give you a better understanding of the role and what the company is looking for in a candidate.

- Visit the company website

- Read industry publications

2. Practice Answering Common Interview Questions

Practice answering common interview questions that you may be asked, such as:

- Tell me about your experience operating asphalt mixing equipment.

- How do you monitor the asphalt production process?

- What are your safety protocols when working with hot asphalt?

3. Highlight Your Skills and Experience

In your interview, be sure to highlight your skills and experience that are relevant to the Hot Mix Operator role. This may include:

- Your experience operating asphalt mixing equipment

- Your knowledge of asphalt production processes

- Your safety record

4. Be Enthusiastic and Professional

First impressions matter, so be enthusiastic and professional during your interview. Dress appropriately, arrive on time, and make eye contact with the interviewers.

- Prepare questions to ask the interviewers

- Follow up with a thank-you note

Next Step:

Now that you’re armed with the knowledge of Hot Mix Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Hot Mix Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini