Feeling lost in a sea of interview questions? Landed that dream interview for Hot Top Liner Helper but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Hot Top Liner Helper interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

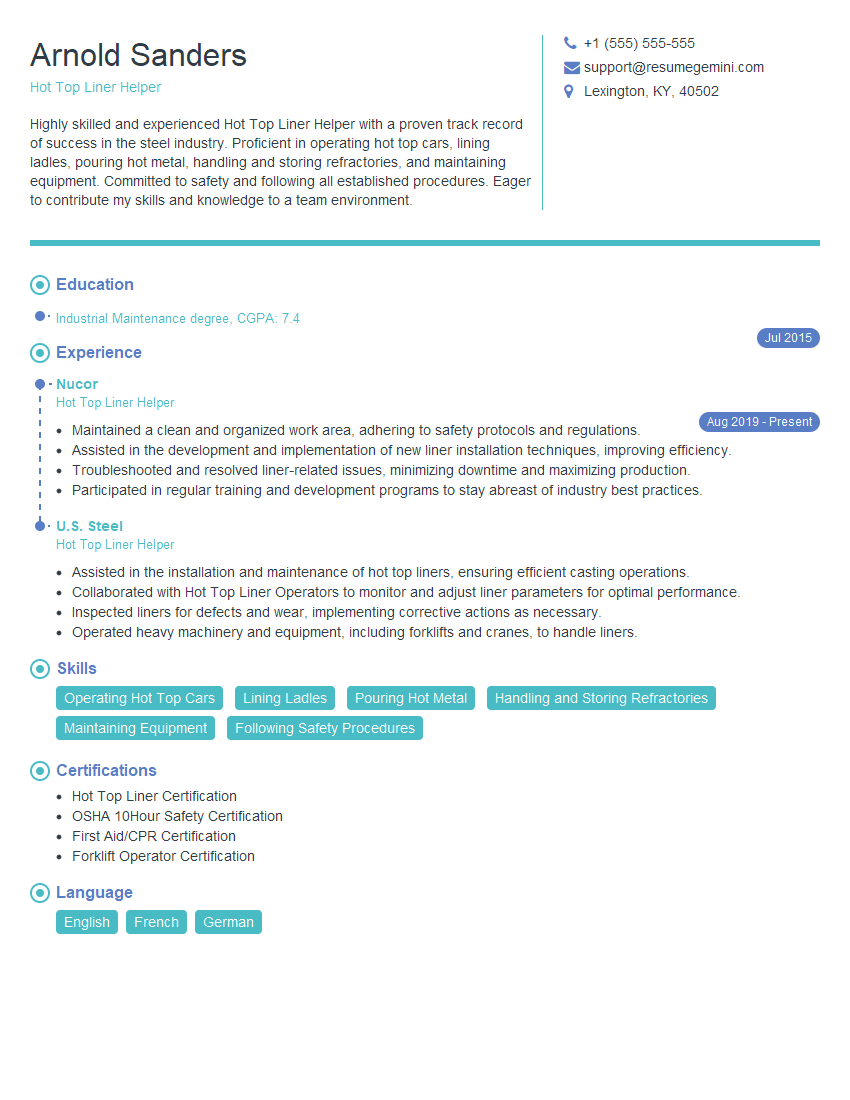

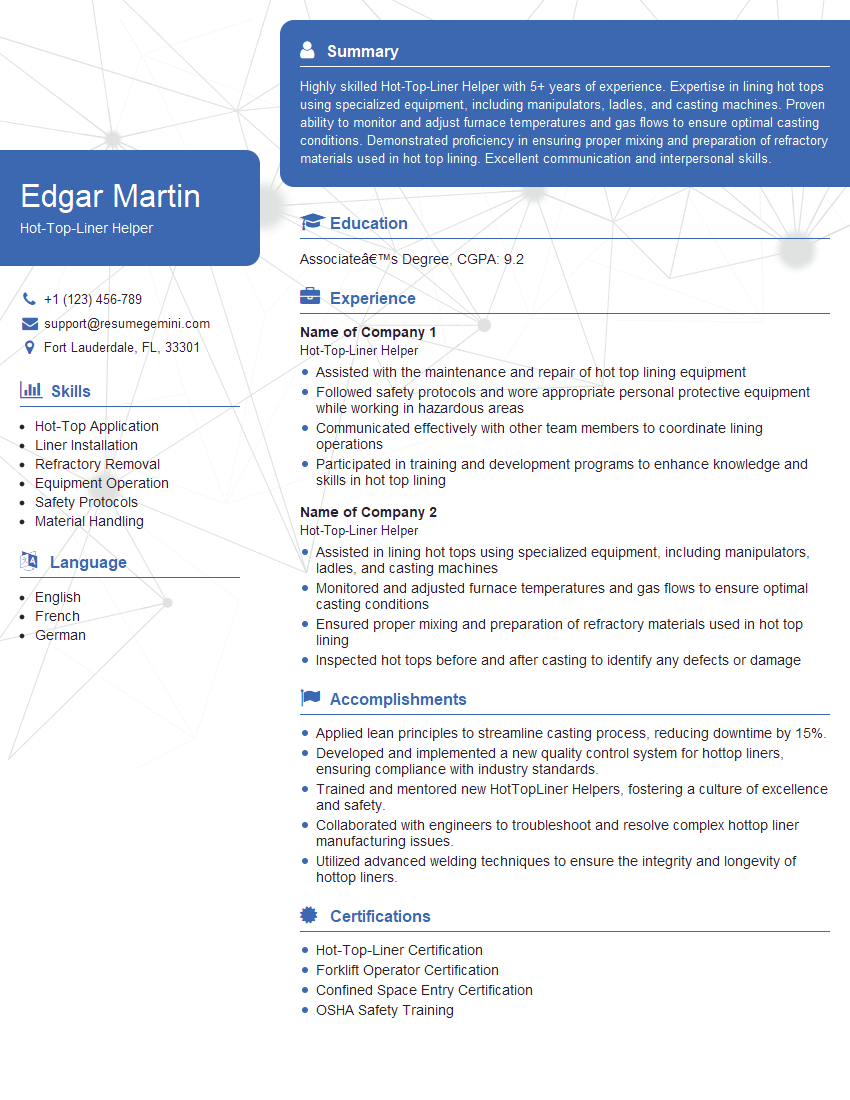

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Hot Top Liner Helper

1. What are the key responsibilities of a Hot Top Liner Helper?

- Assist Hot Top Liner in all aspects of the lining process.

- Follow instructions from Hot Top Liner and Supervisor.

- Operate and maintain equipment and machinery, e.g. conveyor systems.

- Inspect materials and equipment to ensure quality.

- Clean and maintain work area.

2. Describe the hot top lining process?

The hot top lining process involves lining the top of a steel ladle with refractory materials.

- The lining is applied to protect the ladle from damage caused by molten steel.

- The process typically starts with the preparation of the ladle, which involves cleaning and preheating.

- The refractory materials are then applied to the ladle using a variety of methods, such as spraying, casting, or troweling.

- Once the lining is applied, it is allowed to cure before the ladle is put back into service.

3. What are the different types of refractory materials used in hot top lining?

- There are several different types of refractory materials used in hot top lining, each with its own properties and applications.

- Common types include alumina, magnesia, zirconia, and carbon.

- The selection of the right refractory material depends on the specific application and the desired properties, such as thermal conductivity, chemical resistance, and mechanical strength.

4. What are the safety precautions that need to be taken when working with hot top lining materials?

- Hot top lining materials can be hazardous if not handled properly.

- It is important to follow all safety precautions to avoid injuries.

- These precautions include wearing appropriate personal protective equipment, such as gloves, safety glasses, and respirators, and being aware of the potential hazards associated with the materials being used.

5. What are the common problems that can occur during the hot top lining process?

- There are several common problems that can occur during the hot top lining process, such as cracks, spalling, and erosion.

- These problems can be caused by a variety of factors, such as the quality of the materials used, the application methods, and the operating conditions.

- It is important to be aware of these potential problems and to take steps to prevent them from occurring.

6. What is the importance of maintaining a clean work area when working with hot top lining materials?

- Maintaining a clean work area is important for several reasons.

- It helps to prevent contamination of the materials, which can lead to quality problems.

- It also helps to reduce the risk of accidents, as a clean work area is less likely to have tripping hazards or other potential hazards.

7. How do you ensure the quality of the hot top lining?

- Ensuring the quality of the hot top lining is essential for the safe and efficient operation of the steelmaking process.

- There are several steps that can be taken to ensure the quality of the lining, such as using high-quality materials, following proper application procedures, and conducting regular inspections.

8. How do you troubleshoot problems that may arise during the hot top lining process?

- Troubleshooting problems that may arise during the hot top lining process is an important skill for a Hot Top Liner Helper.

- There are several steps that can be taken to troubleshoot problems, such as identifying the source of the problem, determining the cause, and implementing corrective actions.

9. What experience do you have working as a Hot Top Liner Helper?

I have been working as a Hot Top Liner Helper for the past 5 years.

- In my previous role, I was responsible for assisting the Hot Top Liner with all aspects of the lining process.

- This included preparing the ladle, applying the refractory materials, and curing the lining.

- I also conducted regular inspections of the lining to ensure its quality.

10. Why are you interested in working as a Hot Top Liner Helper for our company?

I am interested in working as a Hot Top Liner Helper for your company because I am passionate about the steelmaking industry.

- I believe that my skills and experience would be a valuable asset to your team.

- I am eager to learn more about the hot top lining process and to contribute to the success of your company.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Hot Top Liner Helper.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Hot Top Liner Helper‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Hot Top Liner Helper is responsible for assisting in the production of hot top liners, which are used to insulate the tops of molten metal castings. The key job responsibilities include:

1. Preparation of Materials

Preparing materials such as hot top mix, sand, and binders.

- Measuring and mixing ingredients according to specified proportions.

- Ensuring proper consistency and quality of materials.

2. Operation of Equipment

Operating equipment such as mixers, conveyors, and spray guns.

- Maintaining and calibrating equipment for optimal performance.

- Monitoring equipment to ensure smooth production.

3. Application of Hot Top Liners

Applying hot top liners to the tops of molten metal castings.

- Controlling the thickness and uniformity of the liner.

- Ensuring proper adhesion and coverage.

4. Quality Control

Performing quality checks on hot top liners to ensure they meet specifications.

- Inspecting liners for defects, such as cracks or voids.

- Reporting any non-conformances to supervisors.

Interview Tips

To prepare for an interview for a Hot Top Liner Helper position, consider the following tips:

1. Research the Company and Position

Familiarize yourself with the company’s background, products/services, and specific requirements for the Hot Top Liner Helper role.

- Check the company website, LinkedIn page, and industry news.

- Identify specific skills and experiences that align with the job description.

2. Practice Common Interview Questions

Prepare answers to common interview questions, such as:

- Tell me about yourself.

- Why are you interested in this position?

- Describe your experience with hot top liner production.

- How do you ensure the quality of hot top liners?

3. Highlight Relevant Experience and Skills

Emphasize your experience and skills that are most relevant to the job, including:

- Mixing and handling of hot top mix materials.

- Operation of mixers, conveyors, and spray guns.

- Application and inspection of hot top liners.

- Quality control procedures.

4. Prepare Questions for the Interviewer

Preparing thoughtful questions demonstrates your interest and engagement.

- Inquire about the production process and quality standards.

- Ask about the company’s growth plans and career advancement opportunities.

- Seek clarification on any aspects of the job description that you’re unsure about.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Hot Top Liner Helper, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Hot Top Liner Helper positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.