Are you gearing up for an interview for a Hydropulper Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Hydropulper Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

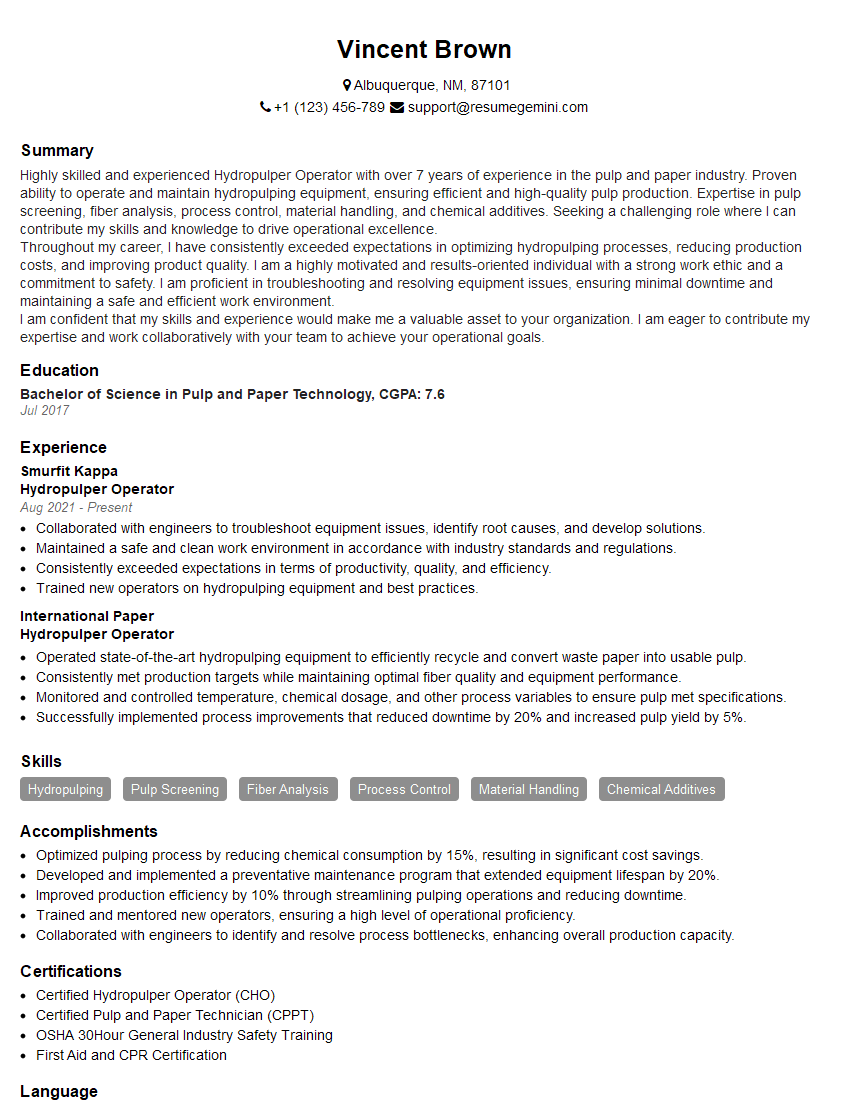

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Hydropulper Operator

1. What are the key responsibilities of a Hydropulper Operator?

As a Hydropulper Operator, my primary responsibilities include:

- Operating and monitoring the hydropulper to produce pulp of specified quality and consistency.

- Feeding raw materials, such as wastepaper, cardboard, or other cellulose-based materials, into the hydropulper.

- Adjusting process parameters like temperature, pH, and chemical additives to optimize pulp quality.

- Monitoring equipment performance and identifying potential issues to ensure smooth operations.

- Maintaining a clean and safe work environment as per established standards and protocols.

2. Describe the process of hydropulping.

Hydropulping is a mechanical pulping process that involves the following steps:

- Preparation of raw materials:

- Feeding of raw materials into the hydropulper:

- Hydromechanical disintegration of materials using a rotating impeller or pulper blades:

- Addition of water and chemicals to create a pulp slurry:

- Separation of impurities and contaminants from the pulp:

- Screening and refining the pulp to achieve desired quality and consistency.

3. How do you troubleshoot common issues encountered in hydropulping operations?

Common issues encountered in hydropulping operations include:

- Poor pulp quality: Can be caused by factors such as incorrect raw material ratio, improper chemical addition, or worn-out equipment.

- Equipment malfunctions: Such as impeller failure, bearing issues, or motor problems, can lead to production interruptions.

- Blockages: Accumulation of debris or oversized materials can obstruct the flow of pulp, causing downtime.

To troubleshoot these issues, I follow a systematic approach:

- Identify the problem and its potential causes:

- Inspect the equipment and raw materials:

- Adjust process parameters or make necessary repairs:

- Monitor the results and make further adjustments as needed.

4. What are the safety precautions that must be followed when operating a hydropulper?

Ensuring safety in hydropulping operations is paramount. I strictly adhere to the following precautions:

- Wear appropriate personal protective equipment (PPE), including gloves, safety glasses, and earplugs.

- Follow lockout/tagout procedures before performing maintenance or repairs.

- Maintain a safe working distance from moving equipment.

- Be aware of potential hazards such as slippery floors, sharp objects, and electrical hazards.

- Report any unsafe conditions or incidents promptly.

5. How do you maintain the efficiency of the hydropulper to ensure optimal performance?

Regular maintenance is crucial to maintain hydropulper efficiency. I follow a comprehensive maintenance plan that includes:

- Daily inspections: To check for wear and tear, leaks, or loose parts.

- Weekly cleaning: To remove debris and buildup, ensuring smooth operation.

- Monthly lubrication: To minimize friction and extend equipment life.

- Scheduled overhauls: To perform thorough inspections, replace worn-out components, and calibrate the system.

6. What are the quality control measures you implement to ensure the production of pulp meets specifications?

I prioritize quality control to meet pulp specifications. My measures include:

- Regular sampling and testing: To monitor pulp consistency, freeness, and other parameters.

- Process control: By adjusting process variables to achieve desired pulp quality.

- Equipment calibration: To ensure accurate measurements and consistent performance.

- Documentation: To maintain records of test results, adjustments made, and any deviations from specifications.

7. Explain the role of consistency regulators in hydropulping and how you adjust them to achieve desired pulp consistency.

Consistency regulators are essential for controlling pulp consistency. I adjust them as follows:

- Identify the desired consistency: Based on product requirements or downstream processes.

- Monitor pulp consistency: Using sensors or manual methods.

- Adjust regulator settings: By opening or closing valves to control the flow of water or pulp.

- Verify consistency: Re-measure the pulp consistency to ensure it meets specifications.

8. Describe the environmental considerations associated with hydropulping and how you minimize its ecological impact.

Environmental responsibility is important in hydropulping. I take the following measures to minimize impact:

- Wastewater treatment: Treat wastewater generated during operations to remove pollutants.

- Raw material optimization: Use recycled materials and minimize waste.

- Energy efficiency: Implement energy-saving practices and optimize equipment performance.

- Emission control: Ensure proper ventilation and minimize air pollution.

9. How do you handle and dispose of hazardous chemicals used in hydropulping operations?

Safe handling and disposal of chemicals is crucial. I follow established protocols:

- Proper storage: Store chemicals in designated, well-ventilated areas.

- Spill prevention: Implement spill containment measures and train personnel on spill response procedures.

- Waste disposal: Dispose of spent chemicals and contaminated materials according to environmental regulations.

- Compliance: Adhere to all applicable regulations and safety guidelines for chemical handling.

10. How do you stay updated with the latest advancements and best practices in hydropulping?

Continuous learning is vital for professional growth. I stay updated through:

- Industry conferences and webinars: Attend industry events to learn about new technologies and innovations.

- Trade publications and journals: Read industry-specific publications to stay abreast of best practices.

- Online courses and certifications: Pursue professional development opportunities to enhance my knowledge and skills.

- Networking: Connect with other professionals in the field to exchange ideas and learn from their experiences.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Hydropulper Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Hydropulper Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Hydropulper Operator plays a crucial role in the paper manufacturing process. Their key job responsibilities include:

1. Hydropulping Operation

Operating and monitoring hydropulper equipment to break down wastepaper and other raw materials into a slurry for paper production.

- Controlling pulp consistency, temperature, and chemical additives to meet product specifications.

- Adjusting machine settings to optimize pulp quality and efficiency.

2. Equipment Maintenance

Performing routine maintenance and repairs on hydropulpers, including lubrication, cleaning, and troubleshooting.

- Inspecting equipment regularly to identify potential issues.

- Coordinating with maintenance personnel for major repairs and overhauls.

3. Quality Control

Monitoring pulp quality and taking corrective actions to ensure adherence to specifications.

- Sampling and testing pulp to measure consistency, brightness, and other parameters.

- Identifying and resolving quality issues to prevent production delays.

4. Safety Compliance

Adhering to all safety regulations and procedures related to hydropulper operation.

- Wearing appropriate personal protective equipment (PPE).

- Following established lockout/tagout procedures.

Interview Tips

To ace the interview for a Hydropulper Operator position, candidates should prepare thoroughly and demonstrate their qualifications and experience.

1. Research the Company and Position

Learn about the company’s history, products, and industry standing. Review the job description carefully to understand the specific requirements and expectations.

- Identify keywords and phrases from the job description and incorporate them into your answers.

- Prepare questions to ask the interviewer, demonstrating your interest and understanding of the role.

2. Highlight Relevant Experience

Emphasize your hands-on experience in hydropulping operations. Quantify your accomplishments and provide specific examples of your contributions.

- Discuss your ability to maintain equipment effectively and resolve technical issues.

- Highlight your knowledge of quality control standards and your commitment to meeting specifications.

3. Showcase Safety Awareness

Demonstrate your understanding of industry safety regulations and your commitment to following proper procedures.

- Explain your experience with lockout/tagout procedures and other safety protocols.

- Emphasize your awareness of potential hazards and your proactive approach to mitigate risks.

4. Practice Your Answers

Prepare your answers to common interview questions and practice them thoroughly. This will help you deliver clear and confident responses.

- Use the STAR method (Situation, Task, Action, Result) to structure your answers.

- Focus on highlighting your skills, experience, and qualifications that are most relevant to the position.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Hydropulper Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!