Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Induction Heating Equipment Setter interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Induction Heating Equipment Setter so you can tailor your answers to impress potential employers.

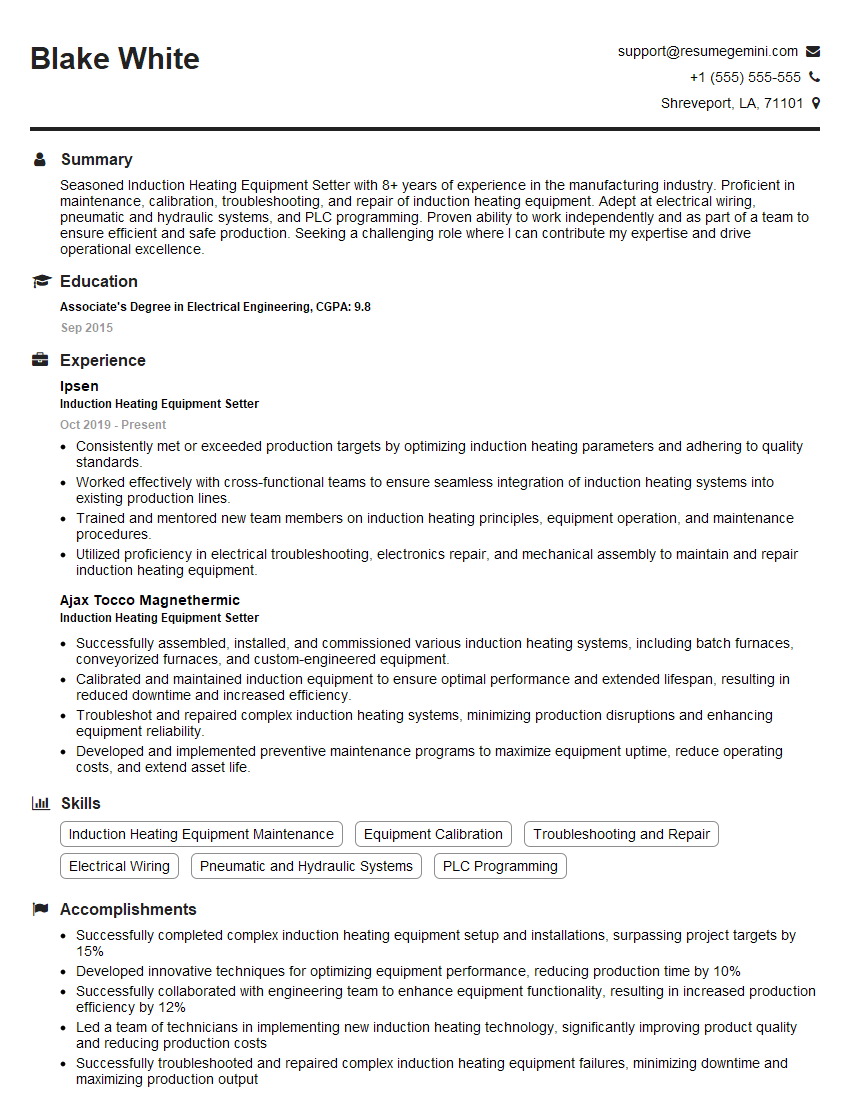

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Induction Heating Equipment Setter

1. How would you ensure the proper alignment of the induction coil and the workpiece?

To ensure proper alignment between the induction coil and the workpiece, I would follow these steps:

- Inspect the workpiece: Examine the workpiece for any surface imperfections or irregularities that could affect alignment.

- Position the coil: Carefully place the induction coil in relation to the workpiece, ensuring it is centered and aligned with the target area.

- Use alignment tools: Utilize alignment tools such as lasers or mechanical jigs to precisely adjust the coil’s position and minimize any potential misalignment.

- Test alignment: Conduct trial runs to verify the alignment and make necessary adjustments as required.

2. What are the key factors to consider when selecting the appropriate induction coil design?

Coil Material:

- Copper: High electrical conductivity, suitable for low-frequency applications.

- Aluminum: Lower electrical conductivity, but lighter and less expensive.

Coil Shape and Size:

- Shape: Solenoid, pancake, or helical, depending on the workpiece and heating requirements.

- Size: Must be appropriate for the workpiece size and power requirements.

Cooling:

- Air-cooled: Suitable for low-power applications.

- Water-cooled: Necessary for high-power applications to prevent overheating.

Tuning:

- Matching the coil’s electrical properties to the power supply for optimal efficiency.

3. How do you troubleshoot and resolve common issues related to induction heating equipment?

To troubleshoot and resolve common issues with induction heating equipment, I would follow a systematic approach:

- Identify the problem: Accurately diagnose the issue based on observations and error messages.

- Check power supply: Ensure a stable and adequate power supply to the equipment.

- Inspect coil and workpiece: Examine the induction coil and workpiece for any damage, misalignment, or contamination.

- Test electrical connections: Verify that all electrical connections are secure and free of corrosion.

- Calibrate equipment: Regularly calibrate the equipment according to manufacturer specifications to maintain accuracy.

4. What safety precautions are essential when operating induction heating equipment?

- Wear appropriate PPE: Gloves, safety glasses, and protective clothing to prevent burns and injuries.

- Ground the equipment: Ensure proper grounding to prevent electrical shocks.

- Maintain a safe distance: Keep a safe distance from the induction coil during operation to avoid exposure to magnetic fields.

- Handle workpieces safely: Use tongs or other tools to move workpieces to prevent burns or accidents.

- Follow manufacturer’s guidelines: Adhere to the manufacturer’s safety instructions and operating procedures.

5. How do you optimize the heating process to achieve desired results with induction heating?

To optimize the heating process with induction heating, I would focus on the following:

- Selecting the right coil: Choosing the appropriate coil design and configuration based on workpiece size, shape, and material.

- Adjusting power and frequency: Optimizing the power output and frequency to match the workpiece and heating requirements.

- Monitoring temperature: Using temperature sensors or pyrometers to monitor and control the temperature of the workpiece.

- Controlling heating time: Determining the optimal heating time to achieve the desired temperature and material properties.

- Quenching and tempering: Applying appropriate quenching and tempering processes to enhance the final properties of the workpiece.

6. Describe the different types of induction heating equipment and their applications.

Coreless Induction Heaters:

- High-frequency, non-contact heating.

- Applications: Surface hardening, annealing, brazing.

Cored Induction Heaters:

- Low-frequency, contact heating.

- Applications: Melting, forging, welding.

RF Induction Heaters:

- Radio frequency range.

- Applications: Semiconductor processing, plastic welding.

7. How do you maintain and calibrate induction heating equipment to ensure accurate and reliable performance?

- Regular cleaning: Removing dust, debris, and contaminants from the equipment.

- Coil inspection: Checking coils for damage or wear and replacing them as needed.

- Electrical testing: Performing electrical tests to verify insulation integrity and component functionality.

- Temperature calibration: Using thermocouples or other temperature sensors to calibrate the equipment for accurate temperature measurement.

- Power calibration: Utilizing power meters to ensure the equipment delivers the desired power output.

8. Explain the principles of electromagnetic induction and how it is applied in induction heating.

Electromagnetic induction involves the generation of an electric current in a conductor when it is exposed to a changing magnetic field. In induction heating, an induction coil creates an alternating magnetic field that induces eddy currents in the workpiece.

- Eddy currents: These circular currents flow within the workpiece, generating heat due to electrical resistance.

- Heat generation: The amount of heat generated depends on factors like power, frequency, and workpiece material properties.

9. How do you determine the appropriate power and frequency settings for induction heating applications?

- Workpiece material: Different materials have varying electrical resistivity, which influences the heating process.

- Workpiece size and shape: Larger or thicker workpieces require higher power and lower frequency.

- Desired heating rate: Faster heating rates require higher power, while slower rates can use lower power.

- Equipment capabilities: Consider the maximum power and frequency output of the induction heating equipment.

10. Describe the advantages and disadvantages of induction heating compared to other heating methods.

Advantages:

- Fast and localized heating: Induction heating generates heat directly in the workpiece, resulting in rapid heating and precise temperature control.

- Non-contact heating: No direct contact with the workpiece eliminates surface damage and contamination.

- Energy efficiency: Induction heating is energy-efficient due to minimal heat loss and targeted heating.

Disadvantages:

- Limited material compatibility: Induction heating is primarily suitable for electrically conductive materials.

- Equipment cost: Induction heating equipment can be more expensive than other heating methods.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Induction Heating Equipment Setter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Induction Heating Equipment Setter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Induction Heating Equipment Setters calibrate, operate, and maintain induction heating equipment to melt, braze, solder, or heat-treat ferrous and non-ferrous metals. They ensure that the equipment is operating at optimal levels and make adjustments as needed. The crucial responsibilities of this role include but are not limited to:

1. Equipment Setup and Calibration

Set up, align, and calibrate induction heating equipment according to specifications and work orders.

- Mount and position induction coils to ensure proper heating of metal components.

- Calibrate power settings, temperature controls, and safety devices to meet process requirements.

2. Operation and Monitoring

Operate induction heating equipment to heat metal components to specific temperatures.

- Monitor process parameters such as temperature, power levels, and cycle times to ensure consistent heating.

- Adjust equipment settings or workpieces as needed to maintain desired temperature levels.

3. Troubleshooting and Maintenance

Troubleshoot and resolve equipment malfunctions, ensuring minimal downtime.

- Inspect equipment regularly for signs of wear or malfunction, and perform preventive maintenance.

- Diagnose and repair electrical and mechanical problems, such as coil failures, power supply issues, and cooling system malfunctions.

4. Safety and Compliance

Ensure compliance with safety regulations and company protocols.

- Follow established safety procedures and wear appropriate protective gear.

- Maintain a clean and organized work area to prevent accidents and optimize productivity.

Interview Tips

Preparing thoroughly for an interview is crucial to showcasing your skills and increasing your chances of success. Here are some effective interview tips and preparation hacks for the Induction Heating Equipment Setter position:

1. Research the Company and Industry

Familiarize yourself with the company’s history, mission, values, and the industry they operate in. This demonstrates your interest and enthusiasm for the role and the company.

- Visit the company’s website, explore their social media pages, and read industry-related news to gather information.

- Identify key industry trends and challenges to show that you are up-to-date and knowledgeable about the field.

2. Practice Answering Common Interview Questions

Prepare for common interview questions by researching the STAR method (Situation, Task, Action, Result). This structured approach helps you provide clear and concise answers that highlight your skills and experience.

- Anticipate questions about your technical abilities, troubleshooting experience, safety practices, and teamwork skills.

- Prepare examples from your previous experiences that demonstrate your proficiency in these areas.

3. Highlight Your Technical Expertise

Emphasize your technical expertise in induction heating equipment. Discuss your experience with different types of equipment, such as solid-state, vacuum-tube, and medium-frequency induction heaters.

- Describe your understanding of induction heating principles, power control techniques, and temperature measurement methods.

- Provide specific examples of how you have used your technical knowledge to solve problems or improve efficiency.

4. Showcase Your Problem-Solving Abilities

Interviewers are keen on assessing your problem-solving skills. Prepare to talk about situations where you encountered challenges, diagnosed issues, and implemented solutions.

- Share examples of how you troubleshooted equipment malfunctions, identified the root cause, and developed effective repair strategies.

- Explain how you analyzed process data, identified inefficiencies, and proposed improvements to optimize heating operations.

5. Demonstrate Your Safety-Oriented Mindset

Emphasize your commitment to safety. Induction heating equipment involves high temperatures and electrical hazards, so interviewers will want to know that you prioritize safety.

- Describe your experience with electrical safety protocols, such as lockout/tagout procedures and grounding techniques.

- Explain how you maintain a clean and organized work area to minimize risks and promote efficiency.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Induction Heating Equipment Setter interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.