Feeling lost in a sea of interview questions? Landed that dream interview for Industrial Welder but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Industrial Welder interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

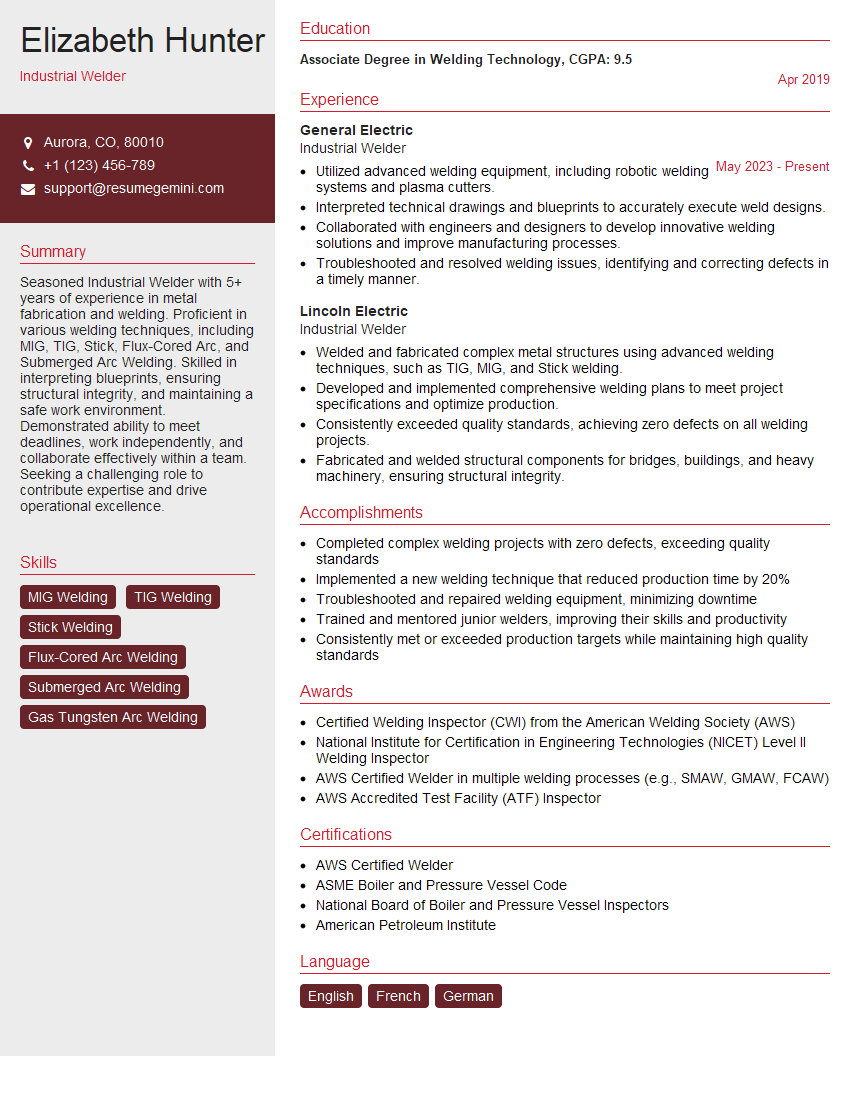

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Industrial Welder

1. What are the different types of welding processes used in industrial settings?

There are several welding processes commonly used in industrial settings, including:

- Shielded Metal Arc Welding (SMAW)

- Gas Metal Arc Welding (GMAW)

- Gas Tungsten Arc Welding (GTAW)

- Flux-Cored Arc Welding (FCAW)

- Submerged Arc Welding (SAW)

2. Describe the safety precautions you take when welding, including the use of personal protective equipment (PPE).

Proper Attire

- Fire-resistant clothing

- Leather welding gloves

- Safety boots

- Helmet with proper shade lens

Workspace Safety

- Adequate ventilation

- Fire extinguisher nearby

- Clean and organized work area

3. What techniques do you use to ensure the quality of your welds?

To ensure the quality of my welds, I follow these techniques:

- Proper joint preparation and cleaning

- Selection of appropriate welding parameters

- Maintaining a steady welding hand

- Visual inspection and non-destructive testing

4. What are the different welding positions and how do you adapt to each one?

The different welding positions are:

- Flat

- Horizontal

- Vertical

- Overhead

I adapt to each position by adjusting my body position, using appropriate welding techniques, and selecting the optimal welding angle for each position.

5. How do you handle welding defects and what steps do you take to prevent them?

I handle welding defects by identifying the type of defect, understanding the cause, and implementing corrective actions. To prevent defects, I follow best practices such as:

- Proper joint preparation

- Selecting appropriate welding parameters

- Maintaining a clean work environment

- Regular equipment maintenance and calibration

6. What types of welding codes and standards are you familiar with?

I am familiar with several welding codes and standards, including:

- AWS D1.1 (Structural Welding Code)

- ASME Boiler and Pressure Vessel Code

- API (American Petroleum Institute) Standards

- ISO 3834 (Quality Requirements for Fusion Welding of Metallic Materials)

7. How do you stay up-to-date with the latest welding technologies and advancements?

I stay up-to-date with the latest welding technologies and advancements through various methods, such as:

- Attending industry conferences and workshops

- Reading technical journals and publications

- Consulting with experts and vendors

- Participating in online forums and discussion groups

8. What is your experience in welding different types of metals and materials?

I have experience in welding various types of metals and materials, including:

- Carbon Steel

- Stainless Steel

- Aluminum

- Cast Iron

- Titanium

I am proficient in handling different material properties and thicknesses.

9. How do you interpret welding drawings and specifications?

I interpret welding drawings and specifications by carefully reviewing the following:

- Joint design and dimensions

- Welding symbols and notations

- Material specifications

- Welding procedure requirements

- Inspection and testing criteria

10. What is your experience in working as part of a team on complex welding projects?

I have extensive experience working as part of a team on complex welding projects, where I have demonstrated the following:

- Effective communication and collaboration

- Problem-solving and decision-making

- Adaptability to changing project requirements

- Quality consciousness and attention to detail

- Meeting project deadlines and objectives

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Industrial Welder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Industrial Welder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Industrial Welders are highly skilled professionals responsible for joining and repairing metal components using various welding techniques. Their primary tasks involve:

1. Welding and Fabrication

Industrial Welders are proficient in numerous welding processes, including arc welding, MIG welding, TIG welding, and plasma welding. They use these techniques to join metal components and manufacture metal structures.

2. Joint Preparation

Prior to welding, Industrial Welders prepare and clean metal surfaces to ensure proper adhesion and joint integrity. This involves grinding, chamfering, and beveling the edges of materials.

3. Equipment Setup and Maintenance

Industrial Welders set up and maintain welding equipment, including welding machines, power sources, and torches. They also inspect and calibrate equipment to ensure optimal performance and safety.

4. Safety Compliance

Industrial Welders strictly adhere to safety regulations and guidelines to minimize risks in the welding environment. They wear protective gear, follow proper ventilation procedures, and handle hazardous materials responsibly.

Interview Tips

To ace an interview for an Industrial Welder position, candidates must prepare thoroughly and demonstrate their skills and knowledge. Here are some helpful tips:

1. Research the Company and Industry

Familiarize yourself with the company’s profile, values, and current projects. Research the welding industry’s trends and technological advancements to demonstrate your interest and understanding.

2. Highlight Relevant Experience

Emphasize your past welding experience and highlight specific techniques you are proficient in. Provide examples of projects where you successfully applied your welding skills to address challenges.

3. Showcase Technical Expertise

Discuss your knowledge of welding codes and standards, such as AWS D1.1 and ASME Boiler and Pressure Vessel Code. Explain how you apply these standards to ensure the quality and safety of your welding.

4. Practice Common Interview Questions

Prepare for common interview questions related to welding techniques, safety procedures, and industry regulations. Practice answering these questions concisely and confidently.

5. Be Prepared for Welding Tests

Some interviews may include welding tests. Practice your welding skills beforehand and bring necessary tools and equipment to demonstrate your proficiency.

6. Ask Insightful Questions

At the end of the interview, ask thoughtful questions about the company’s welding operations, safety policies, and career development opportunities. This shows your genuine interest and enthusiasm for the role.

Next Step:

Now that you’re armed with the knowledge of Industrial Welder interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Industrial Welder positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini