Feeling lost in a sea of interview questions? Landed that dream interview for Ink Maker but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Ink Maker interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

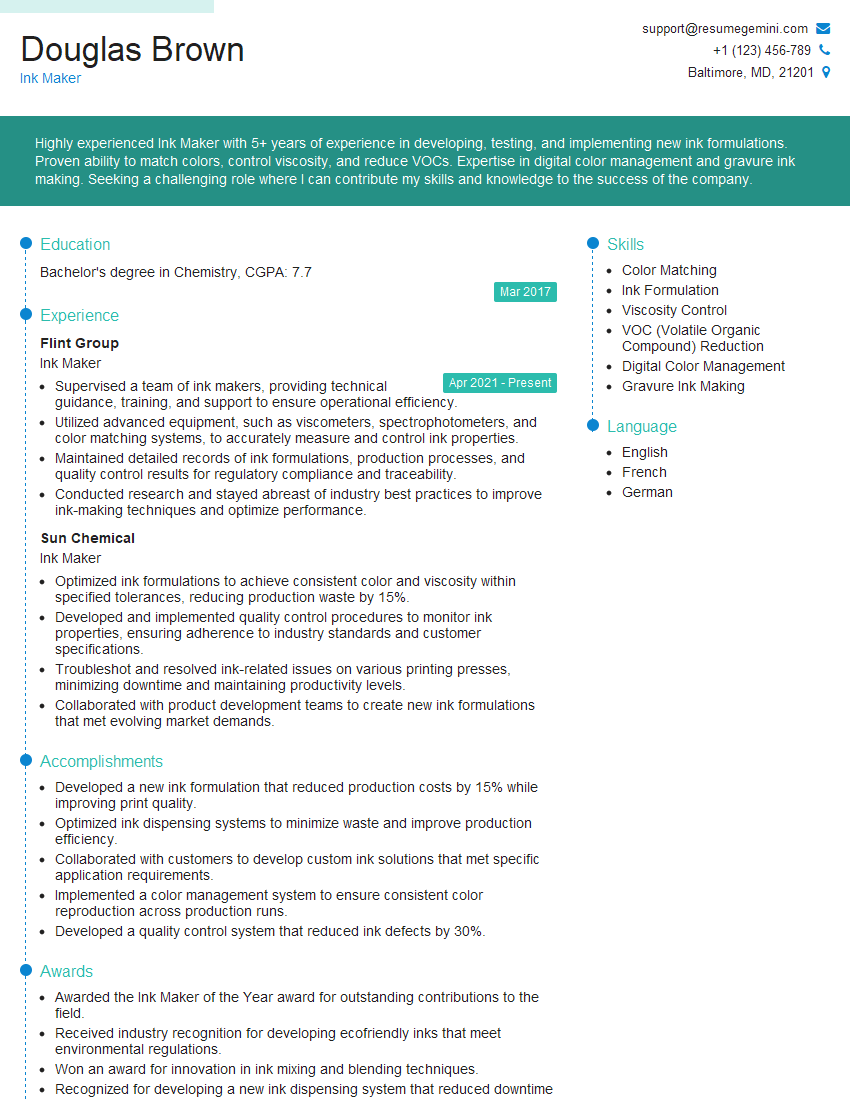

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Ink Maker

1. How do you determine the ideal viscosity for an ink?

In order to determine the ideal viscosity for an ink, several factors need to be considered, including:

- The type of printing process being used

- The type of substrate being printed on

- The desired print quality

- The environmental conditions in which the ink will be used

2. What are the different types of ink drying processes?

- Evaporation: The solvent in the ink evaporates, leaving the pigment particles behind.

- Oxidation: The ink reacts with oxygen in the air to form a solid film.

- Polymerization: The ink undergoes a chemical reaction to form a solid film.

- Coalescence: The ink droplets merge together to form a solid film.

3. What are the most common defects in ink printing?

- Mottling: Uneven distribution of ink on the substrate.

- Bleeding: Ink spreading beyond the desired area.

- Feathering: Ink spreading out into fine lines.

- Set-off: Ink transferring from one printed surface to another.

- Ghosting: A faint image appearing on the reverse side of the substrate.

4. How do you troubleshoot ink printing problems?

- Identify the problem.

- Determine the cause of the problem.

- Develop a solution to the problem.

- Test the solution.

- Implement the solution.

5. What are the safety precautions that must be taken when working with inks?

- Wear appropriate personal protective equipment (PPE), such as gloves, eye protection, and a respirator.

- Avoid skin contact with inks.

- Do not ingest inks.

- Do not breathe in ink fumes.

- Store inks in a well-ventilated area.

- Dispose of inks properly.

6. What are the different types of ink formulations?

- Solvent-based inks: These inks contain a solvent that evaporates, leaving the pigment particles behind.

- Water-based inks: These inks contain water as the main solvent.

- UV-curable inks: These inks cure when exposed to ultraviolet light.

- Electron beam curable inks: These inks cure when exposed to an electron beam.

7. What are the advantages and disadvantages of different ink formulations?

Solvent-based inks

- Advantages: Fast drying, good adhesion, wide color gamut.

- Disadvantages: Can be harmful to the environment, can be flammable.

Water-based inks

- Advantages: Environmentally friendly, non-flammable, can be used on a variety of substrates.

- Disadvantages: Slower drying, narrower color gamut.

UV-curable inks

- Advantages: Fast curing, high gloss, good adhesion.

- Disadvantages: Requires special equipment, can be expensive.

Electron beam curable inks

- Advantages: Fast curing, high resolution, good adhesion.

- Disadvantages: Requires special equipment, can be expensive.

8. How do you calculate the cost of an ink formulation?

- Determine the cost of each raw material.

- Calculate the amount of each raw material needed.

- Multiply the cost of each raw material by the amount needed.

- Add up the costs of all the raw materials.

- Add in the cost of manufacturing.

- Add in the cost of packaging.

- Add in the cost of shipping.

9. How do you ensure the quality of an ink formulation?

- Use high-quality raw materials.

- Follow a strict manufacturing process.

- Test the ink regularly.

- Get feedback from customers.

10. What are the latest trends in ink technology?

- Environmentally friendly inks: Inks that are made from renewable resources and are biodegradable.

- Digital inks: Inks that are designed for use in digital printing processes.

- 3D printing inks: Inks that are used to create 3D objects.

- Security inks: Inks that are used to create security features on documents and packaging.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Ink Maker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Ink Maker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

An Ink Maker is responsible for producing and maintaining inks used in various printing and writing processes. Their key responsibilities include:

1. Ink Formulation and Production

– Developing and optimizing ink formulations to meet specific performance and quality standards.

– Monitoring and controlling production processes to ensure consistent ink quality and efficiency.

2. Ink Testing and Evaluation

– Conducting quality control tests to ensure that inks meet required specifications.

– Evaluating ink performance on different substrates and printing systems.

3. Equipment Maintenance and Troubleshooting

– Maintaining and troubleshooting ink production equipment, ensuring smooth operation and minimizing downtime.

– Performing preventative maintenance to extend equipment lifespan and improve productivity.

4. Material Management and Inventory Control

– Managing raw materials, inventory levels, and waste disposal to ensure cost-effectiveness and regulatory compliance.

– Maintaining accurate records of ink production and inventory.

Interview Preparation Tips

To ace an interview for an Ink Maker position, candidates should consider the following tips:

1. Research the Company and Industry

– Learn about the company’s products, services, and overall industry trends.

– Research the specific role and responsibilities of an Ink Maker within the company.

2. Highlight Relevant Skills and Experience

– Emphasize your experience in ink formulation, production, testing, and troubleshooting.

– Quantify your accomplishments and provide specific examples of your contributions.

3. Demonstrate Knowledge of Printing Processes

– Understand different printing techniques, such as offset, digital, and flexographic printing.

– Discuss your knowledge of how inks interact with various substrates, e.g., paper, plastic, and metal.

4. Prepare for Technical Questions

– Prepare for questions related to ink chemistry, color theory, and quality control.

– Be ready to discuss your understanding of industry standards and regulations, such as ISO and GHS.

5. Showcase Problem-Solving Abilities

– Provide examples of how you have solved technical issues related to ink production or printing processes.

– Discuss your ability to identify and address potential quality concerns.

6. Be Enthusiastic and Professional

– Demonstrate your passion for the industry and your enthusiasm for the role.

– Dress professionally and maintain a positive and courteous attitude.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Ink Maker, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Ink Maker positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.