Are you gearing up for an interview for a Insole Cementer position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Insole Cementer and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

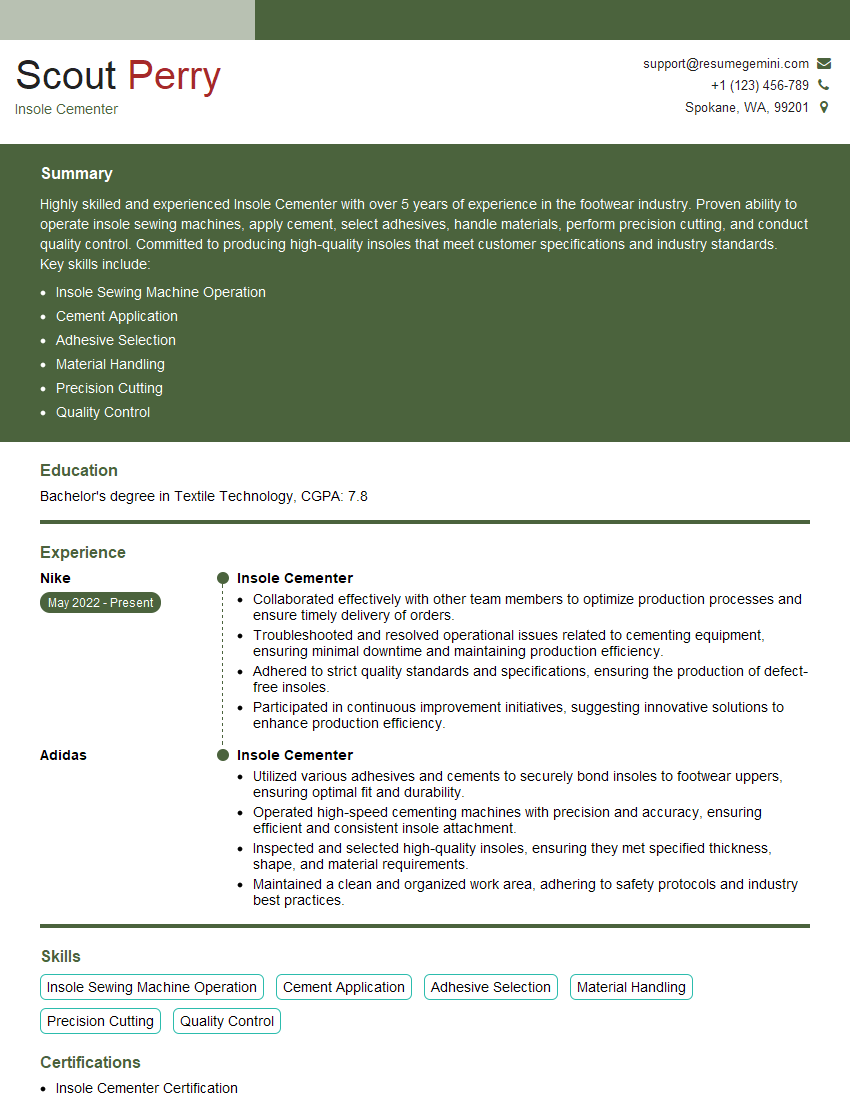

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Insole Cementer

1. Describe the process of cementing insoles to the shoe uppers?

- Prepare the insole and shoe upper by cleaning and roughening the surfaces to be cemented.

- Apply a thin layer of cement to both the insole and the shoe upper.

- Allow the cement to become tacky.

- Align the insole with the shoe upper and press firmly together.

- Weight or clamp the shoe to ensure a strong bond.

- Allow the cement to fully cure before wearing the shoe.

2. What are the different types of cement used for insole cementing?

Water-Based Cement

- Easy to apply and clean up

- Dries quickly

- Not as strong as other types of cement

Solvent-Based Cement

- Stronger than water-based cement

- Takes longer to dry

- Can be more difficult to apply and clean up

Contact Cement

- Very strong bond

- Dries quickly

- Difficult to adjust once applied

3. What are the factors that affect the bond strength of cemented insoles?

- Type of cement used

- Surface preparation of the insole and shoe upper

- Amount of cement applied

- Temperature and humidity during the cementing process

- Curing time

4. How do you ensure that the insoles are cemented in the correct position?

- Use a template or alignment guide

- Mark the insole and shoe upper before applying cement

- Carefully align the insole with the shoe upper

- Press firmly together and hold in place until the cement sets

5. What are the common problems that can occur during insole cementing?

- Insole not properly aligned

- Cement not applied evenly

- Insufficient curing time

- Bond failure

Describe the potential causes and the troubleshooting steps to rectify these problems.

6. How do you maintain and clean insole cementing equipment?

- Keep equipment clean by removing any excess cement

- Store equipment in a cool, dry place

- Inspect equipment regularly for any damage or wear

- Calibrate equipment regularly to ensure accuracy

7. What safety precautions should be taken when working with insole cement?

- Wear proper protective gear, including gloves and a respirator

- Work in a well-ventilated area

- Avoid contact with skin and eyes

- Keep cement away from heat and open flames

- Dispose of cement and used materials properly

8. What are the quality control procedures for insole cementing?

- Inspect insoles for proper alignment and bonding

- Test bond strength using a pull test

- Check shoes for comfort and fit

- Document all quality control checks

9. How do you stay up-to-date on the latest insole cementing techniques?

- Attend training courses and workshops

- Read trade publications

- Network with other insole cementers

- Experiment with different techniques and materials

10. Why are you interested in this Insole Cementer position?

- I have a strong passion for footwear manufacturing, and I am particularly interested in the process of insole cementing.

- I have experience in insole cementing, and I am confident in my ability to perform the job effectively.

- I am a hard worker, and I am always willing to learn new things.

- I am a team player, and I am always willing to help others.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Insole Cementer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Insole Cementer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Insole Cementers play a crucial role in the footwear manufacturing process. Their primary responsibility is to attach insoles to the footwear’s uppers using adhesives and machines.

1. Adhesive Application

Insole Cementers carefully apply adhesives to the insoles and the corresponding upper sections of the footwear.

- Select and use appropriate adhesives for different materials.

- Apply adhesives evenly and accurately using brushes, applicators, or machines.

2. Insole Attachment

Once the adhesives are applied, Insole Cementers align and attach the insoles to the uppers.

- Place insoles correctly within the footwear’s uppers.

- Use machines or hand tools to press and secure the insoles firmly.

3. Alignment and Quality Control

Insole Cementers ensure proper alignment and quality of the attached insoles.

- Inspect insoles for correct placement, adhesion, and overall quality.

- Make adjustments or repairs as needed to meet specifications.

4. Production Monitoring

Insole Cementers monitor their production rates and maintain efficiency.

- Adhere to production schedules and targets.

- Identify and resolve any bottlenecks or issues affecting productivity.

Interview Tips

To effectively prepare for an Insole Cementer interview, consider the following tips:

1. Research the Company and Role

Familiarise yourself with the company’s website, mission, and values. Understand the specific requirements and responsibilities of the Insole Cementer role.

- Read job descriptions thoroughly.

- Identify key skills and qualifications required.

2. Highlight Relevant Experience

Emphasise any previous experience in insole cementing or related fields. Quantify your accomplishments using specific metrics whenever possible.

- Describe your expertise in adhesive application and insole attachment.

- Share examples of how you ensured quality control and met production targets.

3. Demonstrate Attention to Detail

Insole Cementers require a keen eye for detail. Provide examples of your accuracy and precision in previous roles.

- Highlight your ability to follow instructions carefully.

- Discuss your experience in inspecting and identifying defects.

4. Emphasise Communication Skills

Effective communication is crucial in a manufacturing environment. Showcase your ability to communicate clearly with colleagues, supervisors, and clients.

- Describe your experience in working in a team environment.

- Share examples of how you effectively resolved issues or clarified instructions.

5. Prepare for Technical Questions

Be ready to answer technical questions related to insole cementing and footwear production.

- Demonstrate your understanding of different adhesive types and their applications.

- Discuss your knowledge of insole attachment techniques and machinery.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Insole Cementer, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Insole Cementer positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.