Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Instrumentation, Control, and Electrical Technician (I C & E Technician) interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Instrumentation, Control, and Electrical Technician (I C & E Technician) so you can tailor your answers to impress potential employers.

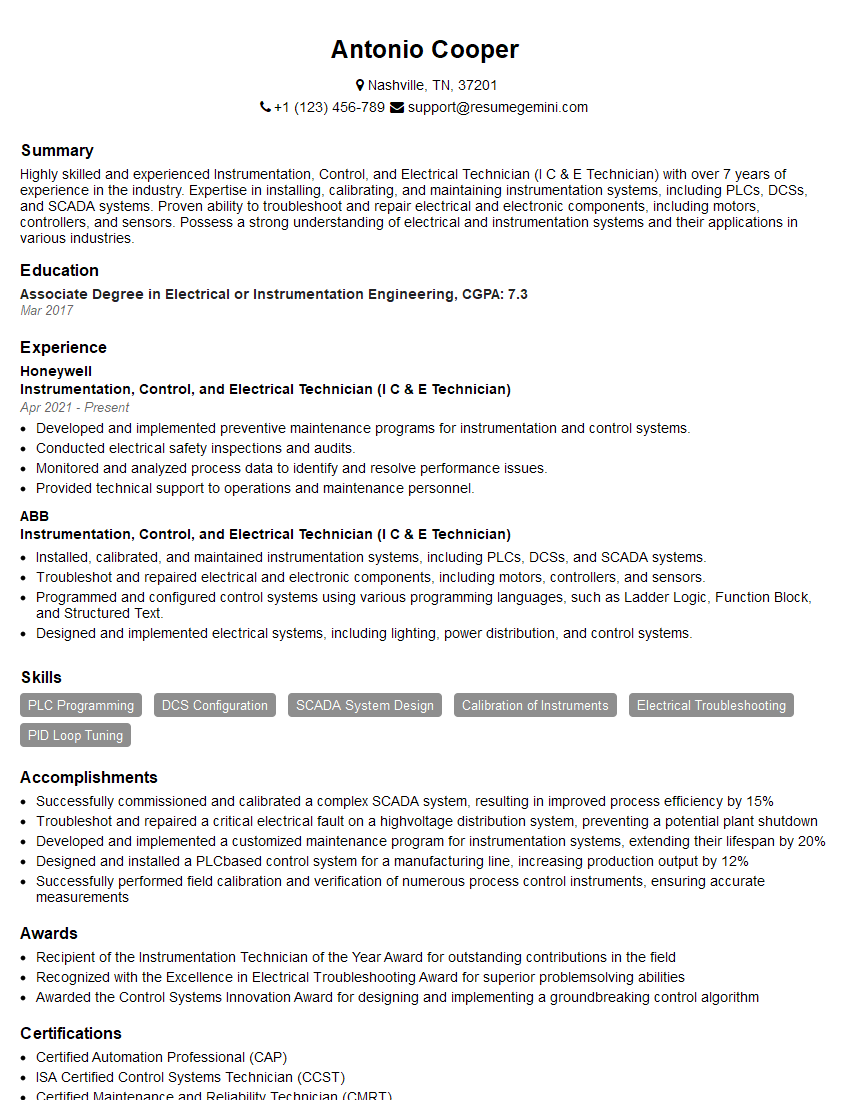

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Instrumentation, Control, and Electrical Technician (I C & E Technician)

1. Describe the different types of sensors used in instrumentation systems?

There are various types of sensors employed in instrumentation systems, each designed to measure specific physical parameters. Some common types include:

- Temperature sensors: Measure temperature variations using principles like thermocouples, RTDs, and thermistors.

- Pressure sensors: Detect and measure pressure variations using methods like bourdon tubes, diaphragm sensors, and strain gauges.

- Flow sensors: Measure the rate of fluid flow using techniques like orifice plates, venturi tubes, and ultrasonic flow meters.

- Level sensors: Monitor liquid or solid levels in tanks or vessels using technologies like float switches, capacitance probes, and ultrasonic sensors.

- Vibration sensors: Detect and measure vibrations in machinery or structures using accelerometers, velocity transducers, and displacement sensors.

- Chemical sensors: Analyze and detect the presence and concentration of specific chemicals or gases, utilizing techniques like electrochemical sensors, optical sensors, and biosensors.

2. Explain the principles of operation for a proportional-integral-derivative (PID) controller?

Proportional Term:

- Responds to current error (e) between measured and desired value.

- Adjustment proportional to the magnitude of the error.

Integral Term:

- Accumulates error over time (∫e dt).

- Compensates for steady-state errors by gradually adjusting the output.

Derivative Term:

- Responds to the rate of change of error (de/dt).

- Improves response time and stability.

3. Discuss the different types of electrical wiring methods?

There are several electrical wiring methods employed in industrial and commercial settings, each with its advantages and applications:

- Conduit wiring: Wires are protected within metal or plastic conduits, providing mechanical protection and flexibility.

- Cable tray wiring: Cables are laid in open trays, offering easy access and maintenance, but requiring more space.

- Busway wiring: Prefabricated metal enclosures carry high-current electrical power distribution, providing high capacity and reliability.

- Surface raceway wiring: Wires are run on the surface of walls or ceilings using plastic raceways, allowing for easy modifications but compromising aesthetics.

- Underground wiring: Cables are buried directly into the ground, providing protection from external factors but requiring excavation for maintenance.

4. How would you troubleshoot a faulty motor control circuit?

To troubleshoot a faulty motor control circuit, I would follow a systematic approach:

- Verify power supply: Ensure that power is available at the input terminals of the motor control circuit.

- Check control inputs: Examine if the control signals (e.g., start/stop commands) are properly reaching the circuit.

- Inspect electrical connections: Examine all electrical connections for loose wires, damaged terminals, or poor contacts.

- Test motor: Disconnect the motor and perform continuity and resistance tests to identify any issues within the motor windings.

- Analyze control components: Test and inspect individual control components (e.g., relays, contactors, switches) to identify any malfunctioning elements.

5. Explain the importance of grounding in electrical systems?

Grounding in electrical systems serves several crucial purposes:

- Safety: Provides a low-resistance path for fault currents to flow, preventing dangerous voltages from reaching equipment or personnel.

- Voltage referencing: Establishes a common reference point for electrical circuits, ensuring proper voltage levels and minimizing noise.

- Static discharge: Dissipates static charges that can accumulate on equipment, reducing the risk of electrostatic discharge (ESD) damage.

- Lightning protection: Diverts lightning energy safely into the ground, protecting sensitive electronic equipment.

- Reliability: Improves system reliability by preventing voltage spikes and transients from damaging electrical components.

6. Describe the various methods of programmable logic controller (PLC) programming?

PLC programming can be accomplished through several methods:

- Ladder logic: Uses graphical symbols representing electrical schematics, making it intuitive for electricians and maintenance personnel.

- Function block diagram (FBD): Employs graphical blocks representing logic functions and data flow, providing a structured and modular approach.

- Structured text (ST): Text-based programming language that follows standard programming constructs, offering flexibility and ease of debugging.

- Instruction list (IL): Low-level programming language that provides direct access to PLC instructions, allowing for precise control and optimization.

- Sequential function chart (SFC): Graphical programming language that focuses on sequential operations and state transitions, simplifying complex control logic.

7. Explain the principles of operation for a DC motor?

A DC motor operates on the principle of electromagnetic induction:

- When a current flows through a coil (armature) placed in a magnetic field (stator), a force is generated due to the interaction between the magnetic fields.

- This force causes the armature to rotate, converting electrical energy into mechanical energy.

- The direction of rotation is determined by the direction of current flow and the polarity of the magnetic field.

8. How would you isolate a fault in a complex electrical system?

To isolate a fault in a complex electrical system, I would follow these steps:

- Divide and conquer: Break down the system into smaller sections and test each section individually.

- Use test equipment: Employ multimeters, insulation testers, and other diagnostic tools to identify faulty components.

- Analyze system behavior: Observe the system’s response to different inputs and stimuli to identify the source of the fault.

- Check for loose connections: Examine electrical connections for any loose wires or terminals that may cause intermittent faults.

9. Describe the different types of fieldbus communication protocols?

Fieldbus communication protocols enable data exchange between devices in an industrial automation system:

- PROFIBUS: Widely used in manufacturing and process automation, supporting various topologies and data rates.

- Modbus: A simple and cost-effective protocol for serial communication, commonly used in building automation and HVAC systems.

- CAN (Controller Area Network): Designed for automotive applications but also used in industrial settings, known for its high speed and reliability.

- Ethernet/IP: An Ethernet-based protocol that combines industrial automation capabilities with standard Ethernet infrastructure.

- HART (Highway Addressable Remote Transducer): A communication protocol specifically designed for smart transmitters, enabling remote configuration and diagnostics.

10. How would you ensure the safety of electrical equipment in a hazardous area?

To ensure the safety of electrical equipment in a hazardous area, I would adhere to the following guidelines:

- Hazardous area classification: Understand the classification of the hazardous area (e.g., Zone 0, Zone 1, Zone 2) and select equipment rated for the specific hazard level.

- Explosion-proof enclosures: Utilize electrical enclosures that are designed to prevent the ignition of flammable gases or vapors in the event of an internal explosion.

- Intrinsic safety: Employ intrinsically safe equipment that operates at very low voltage and current levels, minimizing the risk of spark generation.

- Proper installation: Ensure that electrical equipment is installed according to manufacturer’s specifications and applicable codes, including proper grounding and protection against mechanical damage.

- Regular maintenance and inspection: Conduct periodic inspections and maintenance to identify potential hazards and ensure the continued safe operation of the equipment.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Instrumentation, Control, and Electrical Technician (I C & E Technician).

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Instrumentation, Control, and Electrical Technician (I C & E Technician)‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

- Install, maintain, and repair instrumentation, control, and electrical systems and components.

- Troubleshoot and diagnose problems with instrumentation, control, and electrical systems and components.

- Calibrate and adjust instrumentation, control, and electrical systems and components.

- Develop and implement maintenance plans for instrumentation, control, and electrical systems and components.

- Supervise and train other technicians in the installation, maintenance, and repair of instrumentation, control, and electrical systems and components.

Interview Tips

-

Research the Company and the Position

Before the interview, take some time to research the company and the specific position you are applying for. This will help you understand the company’s culture, values, and goals, and tailor your answers to the interviewer’s questions.

-

Practice Your Answers to Common Interview Questions

There are a few common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” Practice your answers to these questions in advance so that you can deliver them confidently and concisely.

-

Be Prepared to Talk About Your Experience

The interviewer will want to know about your experience in the field of instrumentation, control, and electrical systems and components. Be prepared to talk about your skills and accomplishments, and how they relate to the requirements of the job.

-

Ask Questions

At the end of the interview, be sure to ask the interviewer any questions that you have about the company, the position, or the hiring process. This will show that you are interested in the opportunity and that you are taking the interview seriously.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Instrumentation, Control, and Electrical Technician (I C & E Technician) interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!