Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Insulation Board Coater Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Insulation Board Coater Operator so you can tailor your answers to impress potential employers.

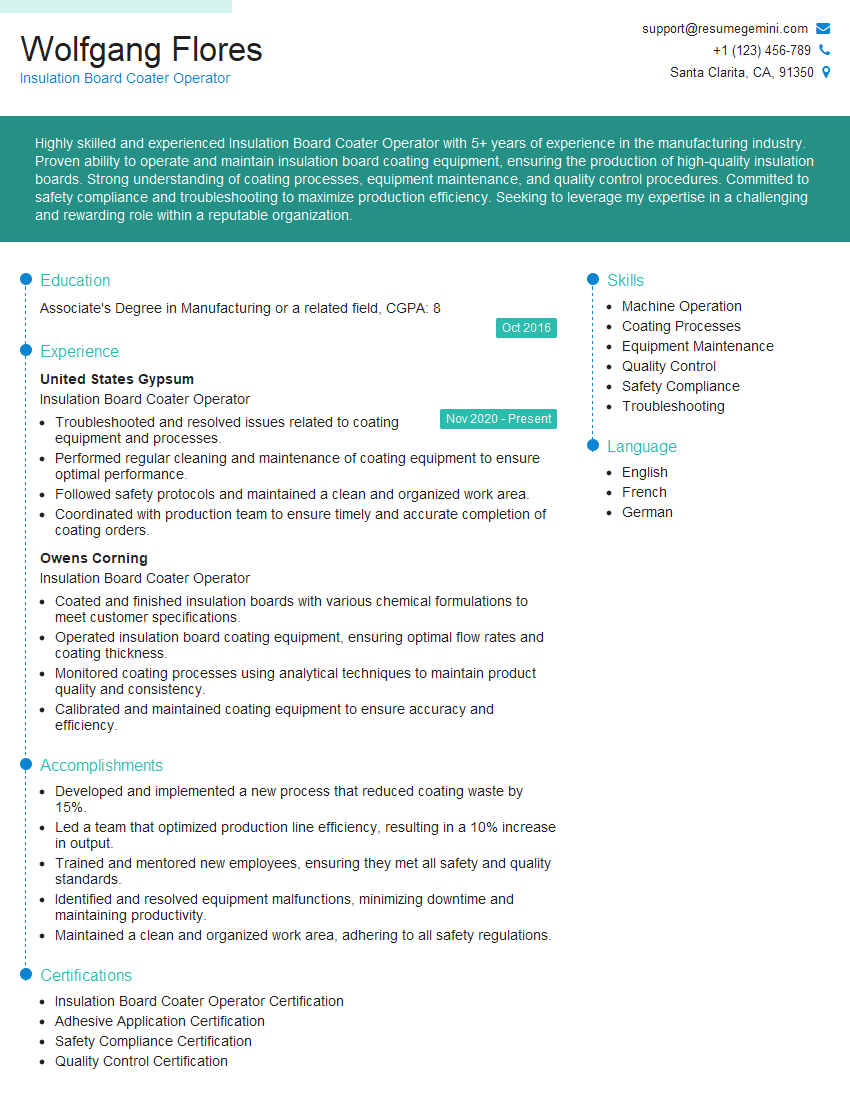

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Insulation Board Coater Operator

1. What are the different types of insulation board coating machines?

- Roll coating machines

- Curtain coating machines

- Spray coating machines

2. What are the key factors to consider when selecting an insulation board coating machine?

Speed and efficiency

- The speed of the machine will determine how much product you can produce in a given amount of time.

- The efficiency of the machine will determine how much product is wasted during the coating process.

Coating quality

- The quality of the coating will determine the durability and performance of the insulation board.

- Factors that affect coating quality include the type of coating material, the thickness of the coating, and the application method.

Maintenance and operating costs

- The cost of maintaining and operating the machine will affect your overall production costs.

- Factors that affect maintenance and operating costs include the frequency of maintenance, the cost of replacement parts, and the energy consumption of the machine.

3. What is the process of coating insulation board?

- The insulation board is first cleaned to remove any dirt or debris.

- The coating material is then applied to the board using a coating machine.

- The coating is then dried and cured to form a durable finish.

4. What are the common problems that can occur during insulation board coating?

- Uneven coating thickness

- Blisters or bubbles in the coating

- Cracking or peeling of the coating

Causes and solutions for uneven coating thickness

- The coating machine may not be calibrated correctly.

- The coating material may be too thick or too thin.

- The coating speed may be too fast or too slow.

Causes and solutions for blisters or bubbles in the coating

- The insulation board may not be dry enough before coating.

- The coating material may contain air bubbles.

- The coating temperature may be too high.

Causes and solutions for cracking or peeling of the coating

- The coating material may not be compatible with the insulation board.

- The coating may be applied too thick or too thin.

- The coating may not be cured properly.

5. How do you ensure the quality of the coated insulation board?

- Inspect the insulation board for any defects before coating.

- Calibrate the coating machine regularly.

- Use high-quality coating materials.

- Follow the coating process carefully.

- Inspect the coated insulation board for any defects after coating.

6. What are the safety precautions that should be taken when operating an insulation board coating machine?

- Wear appropriate safety gear, including gloves, safety glasses, and a respirator.

- Keep the work area clean and free of debris.

- Follow the manufacturer’s instructions for operating the machine.

- Do not operate the machine if you are not trained to do so.

7. What are your strengths and weaknesses as an Insulation Board Coater Operator?

- Strengths:

- I have over 5 years of experience operating insulation board coating machines.

- I am proficient in all aspects of the coating process, including machine setup, operation, and maintenance.

- I have a strong understanding of the different types of coating materials and their applications.

- I am committed to producing high-quality coated insulation board.

- Weaknesses:

- I am not yet familiar with the specific coating machine that is used in your facility.

- I am still learning about the different types of insulation board and their specific coating requirements.

8. What are your salary expectations?

My salary expectations are in the range of $25-$30 per hour.

9. Why are you interested in this position?

I am interested in this position because it is a great opportunity to use my skills and experience in a challenging and rewarding role. I am confident that I have the skills and experience necessary to be successful in this position and I am eager to learn more about your company and the insulation board coating process.

10. Do you have any questions for me?

I do not have any questions at this time. Thank you for your time and consideration.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Insulation Board Coater Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Insulation Board Coater Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

As an Insulation Board Coater Operator, you will play a crucial role in the production process of insulation boards, ensuring they meet the required specifications. Your responsibilities will encompass:

1. Machine Operation

Efficiently operate and monitor the insulation board coating machine, ensuring smooth production.

- Maintain optimal machine settings to achieve desired coating quality and thickness.

- Troubleshoot and resolve machine malfunctions promptly to minimize downtime.

2. Quality Control

Conduct thorough quality checks on the coated insulation boards, verifying their adherence to established standards.

- Inspect boards for defects, such as bubbles, cracks, or uneven coating.

- Record inspection results and report any non-conforming boards for corrective action.

3. Material Handling

Safely handle and move raw materials, coated insulation boards, and waste products.

- Load and unload materials efficiently using forklifts or other equipment.

- Dispose of waste materials responsibly, adhering to environmental regulations.

4. Process Improvement

Continuously evaluate and suggest improvements to the coating process to enhance efficiency and quality.

- Identify potential areas for optimization and develop innovative solutions.

- Collaborate with team members to implement improvements that increase productivity.

Interview Tips

To ace the interview for the Insulation Board Coater Operator position, follow these comprehensive tips:

1. Research the Company and Role

Thoroughly research the insulation board manufacturing company and the specific responsibilities of the Coater Operator role. This knowledge will demonstrate your genuine interest and understanding of the position.

- Visit the company website, LinkedIn page, and industry news articles to gather information.

- Review the job posting carefully, paying attention to the required qualifications and skills.

2. Highlight Relevant Skills and Experience

Emphasize your relevant skills and experience in the interview. Focus on your abilities in:

- Operating coating machinery

- Conducting quality inspections

- Handling materials safely

- Problem-solving and process improvement

3. Quantify Your Accomplishments

When describing your experience, use specific examples to quantify your accomplishments. Provide concrete numbers and data to demonstrate your impact.

- Example: “Increased coating machine output by 15% through process optimizations.”

- Example: “Reduced defect rate on coated insulation boards by 10% by implementing new inspection procedures.”

4. Be Prepared for Technical Questions

Expect technical questions related to the equipment, processes, and materials used in insulation board coating. Study the following areas:

- Coating technologies and their applications

- Coating quality parameters and testing methods

- Safety procedures for handling insulation materials

- Process control techniques for optimizing coating consistency

5. Express Enthusiasm and Career Goals

Throughout the interview, convey your enthusiasm for the insulation board industry and your career goals. Explain how this role aligns with your aspirations and how you aim to contribute to the company’s success.

- Example: “I am eager to join your team and leverage my skills to drive quality and efficiency in your insulation board coating operations.”

- Example: “My long-term goal is to become a Production Supervisor in the insulation manufacturing industry, and this role would provide me with valuable experience and skills.”

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Insulation Board Coater Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.