Are you gearing up for an interview for a Insulation Cutter position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Insulation Cutter and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

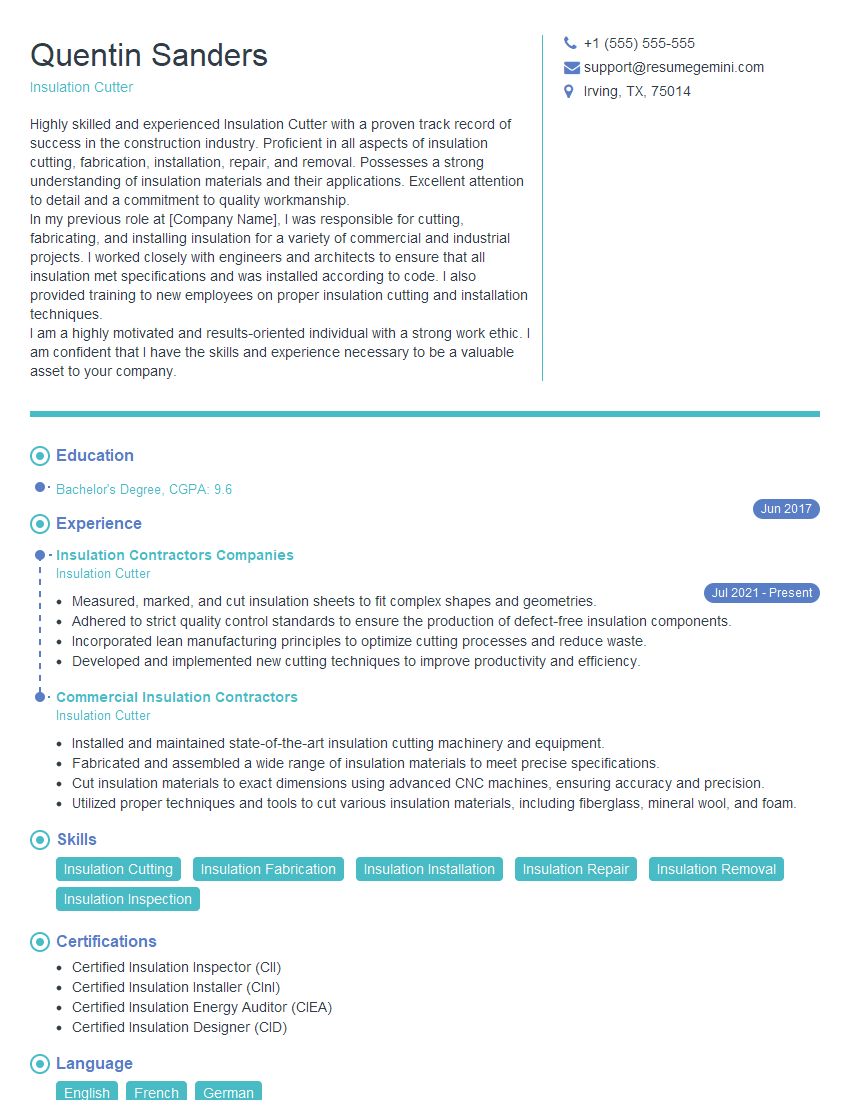

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Insulation Cutter

1. What types of insulation materials have you worked with?

- Mineral wool (Rock wool, Glass wool, Slag wool)

- Polystyrene (EPS, XPS)

- Polyurethane (PU, PIR, XPS)

- Aerogel

- Cellulose

2. What are the different types of insulation cutter tools?

Hot wire cutters

- Manual hot wire cutters

- CNC hot wire cutters

Cold knife cutters

- Handheld cold knife cutters

- Automated cold knife cutters

Water jet cutters

3. What are the advantages and disadvantages of hot wire cutters?

- Advantages

- Precise cuts

- Fast cutting speed

- Suitable for cutting complex shapes

- Disadvantages

- Can generate fumes

- Can damage insulation if not used properly

- Not suitable for cutting all types of insulation

4. What are the safety precautions that should be taken when using insulation cutter tools?

- Wear appropriate safety gear (gloves, eye protection, etc.)

- Ventilate the work area to prevent fume inhalation

- Inspect the cutter tool before each use

- Never cut insulation that is energized

- Follow the manufacturer’s instructions for safe operation

5. What are the factors that affect the quality of insulation cuts?

- Type of insulation material

- Thickness of insulation

- Type of insulation cutter tool

- Cutting speed

- Cutting temperature (for hot wire cutters)

6. How do you troubleshoot common problems with insulation cutter tools?

- Fumes or smoke: Check ventilation, clean or replace the cutting wire/blade

- Poor cut quality: Adjust cutting speed, temperature, or inspect the cutter tool for damage

- Tool overheating: Allow the tool to cool, check for proper ventilation

- Motor failure: Contact the manufacturer or a qualified electrician

7. What are the different types of insulation cutting techniques?

- Straight cuts

- Curved cuts

- Angle cuts

- Beveled cuts

- Notched cuts

8. What are the applications of insulation cutters?

- Insulating buildings

- Manufacturing insulated products

- Packaging and shipping insulation

- Creating custom insulation shapes

9. What are the latest advancements in insulation cutting technology?

- CNC hot wire cutters with advanced software

- Laser insulation cutters

- Water jet insulation cutters

10. What are the challenges faced in insulation cutting?

- Cutting complex shapes

- Achieving precise cuts

- Minimizing waste

- Ensuring safety

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Insulation Cutter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Insulation Cutter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Insulation Cutters are responsible for cutting and shaping insulation materials to fit specific requirements, ensuring proper insulation and energy efficiency in buildings. Their responsibilities include:

1. Insulation Cutting and Shaping

a. Accurately cut and shape insulation materials using specialized tools and techniques.

b. Ensure precise dimensions and fit for proper installation.

2. Material Selection and Inspection

a. Select appropriate insulation materials based on project specifications.

b. Inspect insulation materials for defects or damage before cutting.

3. Installation Support

a. Assist with the installation of insulation materials in walls, ceilings, and other areas.

b. Collaborate with other tradespeople to ensure proper integration of insulation.

4. Equipment Maintenance

a. Maintain and calibrate cutting tools and equipment to ensure accuracy and productivity.

b. Adhere to safety regulations and follow proper operating procedures.

Interview Tips

To ace an interview for an Insulation Cutter position, it is crucial to prepare thoroughly and demonstrate a strong understanding of the role and industry. Here are some tips:

1. Research the Company and Position

a. Gather information about the company, its services, and the specific requirements for the Insulation Cutter position.

b. This knowledge will help you tailor your answers to the interviewer’s questions and show that you are genuinely interested in the opportunity.

2. Highlight Relevant Skills and Experience

a. Emphasize your proficiency in using insulation cutting tools and techniques.

b. Share examples of projects where you successfully cut and shaped insulation materials to meet specific requirements.

3. Demonstrate Attention to Detail

a. Insulation Cutters must be meticulous and precise in their work. Share examples where you paid close attention to detail and achieved accurate results.

b. Explain how you ensure the proper fit and dimensions of insulation materials during installation.

4. Emphasize Safety Awareness

a. Safety is paramount in this industry. Discuss your knowledge of safety regulations and your commitment to following proper operating procedures.

b. Share experiences where you have identified potential hazards and taken measures to mitigate risks.

5. Practice Common Interview Questions

a. Prepare for common interview questions related to your skills, experience, and motivation for the role.

b. Rehearse your answers to ensure clarity and confidence during the interview.

6. Ask Informed Questions

a. Asking thoughtful questions shows that you are engaged and interested in the position.

b. Prepare questions related to the company’s insulation practices, industry trends, or the specific project you will be working on.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Insulation Cutter, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Insulation Cutter positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.