Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Insulation Professional interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Insulation Professional so you can tailor your answers to impress potential employers.

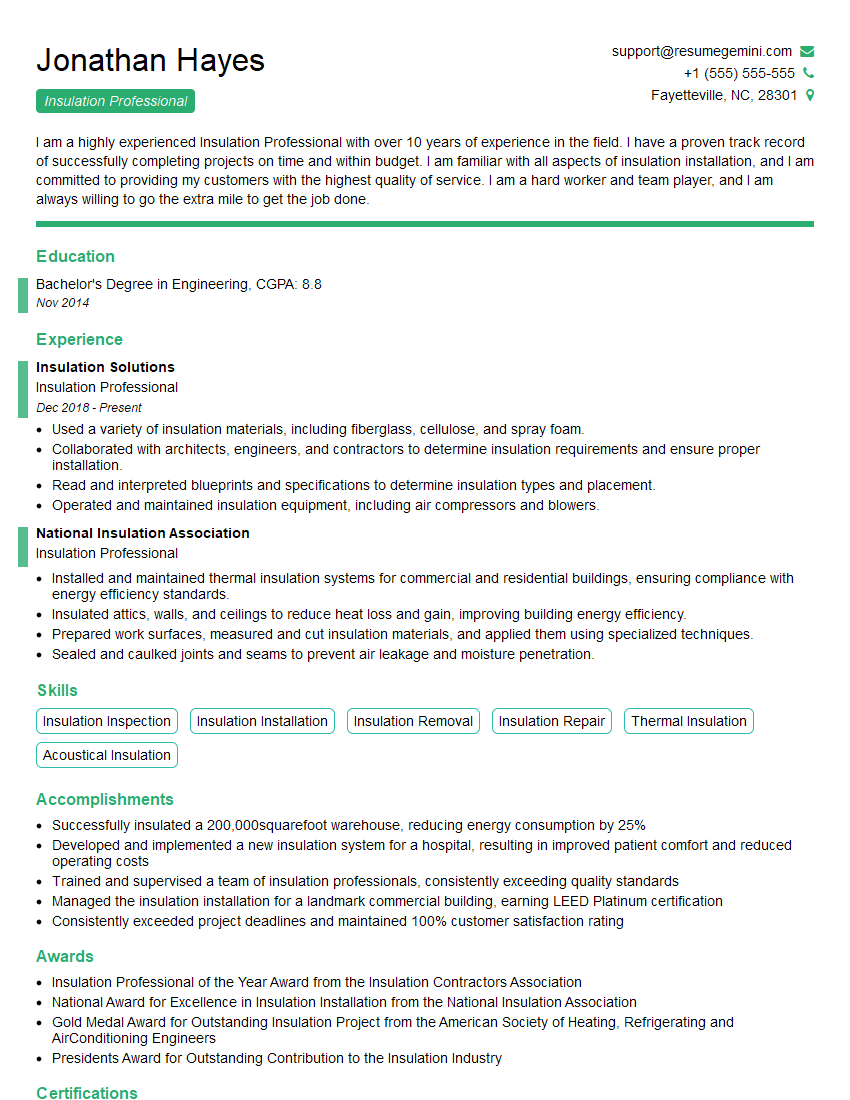

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Insulation Professional

1. What are the different types of insulation materials and their applications?

There are various types of insulation materials, each with specific applications and properties. Some common types include:

- Fiberglass: A widely used insulation material made from glass fibers, providing excellent thermal resistance and acoustic absorption.

- Cellulose: An environmentally friendly option made from recycled paper, offering good insulation value and soundproofing properties.

- Polystyrene (EPS and XPS): Synthetic foams that provide high thermal resistance, moisture resistance, and durability.

- Polyurethane: A spray foam insulation that expands and conforms to the shape of the surface, providing excellent airtightness and insulation.

- Mineral wool: Made from natural or synthetic fibers, offering fire resistance, sound absorption, and thermal insulation.

2. Describe the process of installing insulation in a residential building.

Site Preparation

- Assess the building’s insulation requirements based on climate, structure, and energy codes.

- Clear the installation area, remove existing insulation (if any), and ensure proper ventilation.

Insulation Installation

- Choose the appropriate insulation material and thickness based on the desired R-value.

- Cut and fit insulation to the desired size and shape, ensuring proper coverage and minimizing gaps.

- Secure insulation using appropriate fasteners, adhesives, or mechanical systems to prevent movement and maintain airtightness.

Inspection and Completion

- Inspect the installed insulation to ensure proper coverage, compression, and adherence to building codes.

- Seal any gaps or penetrations with appropriate materials to maintain airtightness and prevent energy loss.

3. What safety precautions should be taken when working with insulation?

Working with insulation requires adherence to proper safety precautions to minimize health risks. These include:

- Wear appropriate protective gear, including gloves, eye protection, and a respirator when handling fiberglass or other irritating materials.

- Avoid inhaling insulation dust or fibers, as they can cause respiratory irritation and long-term health issues.

- Handle sharp objects and tools with care to avoid punctures or cuts from insulation materials.

- Be aware of electrical hazards and take precautions when working near electrical lines or equipment.

- Follow manufacturer’s instructions and safety guidelines for handling and installing insulation.

4. How do you calculate the R-value of insulation?

The R-value of insulation is a measure of its thermal resistance. It is calculated as the thickness of the insulation material divided by its thermal conductivity. The higher the R-value, the better the insulation’s ability to resist heat flow.

Formula: R-value = Thickness / Thermal Conductivity

5. What are the advantages of using spray foam insulation?

- Excellent Airtightness: Spray foam expands and seals gaps, creating an airtight barrier that minimizes air leakage and improves energy efficiency.

- High R-value: Spray foam has a high R-value per inch, providing superior thermal insulation and reducing energy costs.

- Moisture Resistance: Spray foam is moisture-resistant, preventing moisture penetration and potential damage to the building structure.

- Soundproofing: Spray foam absorbs and dampens sound, reducing noise transmission and improving acoustic comfort.

- Durability: Spray foam is a durable material that maintains its insulation properties and integrity over time.

6. How do you handle insulation waste and dispose of it properly?

- Fiberglass and Cellulose: Wear gloves and a mask, collect the waste in bags, and dispose of it in a designated landfill.

- Polystyrene: Recycle polystyrene waste at designated recycling facilities or dispose of it in landfills that accept plastic.

- Mineral Wool: Dispose of mineral wool waste in a landfill, following local regulations and guidelines.

- Spray Foam: Remove uncured spray foam with a solvent or mechanical means, and cure and dispose of the waste according to manufacturer’s instructions.

- Follow Local Regulations: Adhere to local regulations and guidelines for waste disposal to ensure proper environmental management.

7. What are the challenges you have faced during an insulation installation project? How did you overcome them?

Challenge: Complex Building Structure

Solution: Used a combination of insulation materials and techniques to fit odd-shaped areas and ensure proper coverage.

Challenge: Moisture Concerns

Solution: Installed a vapor barrier and used moisture-resistant insulation to prevent moisture penetration.

Challenge: Limited Access

Solution: Used specialized tools and equipment to reach difficult areas and complete the insulation installation.

8. How do you stay updated with the latest insulation technologies and industry best practices?

- Attend industry conferences and workshops.

- Read trade publications and technical articles.

- Participate in online forums and discussions.

- Seek training and certification from manufacturers and industry organizations.

- Follow reputable industry experts and thought leaders.

9. What is your experience with energy efficiency codes and regulations related to insulation?

- Familiar with the International Energy Conservation Code (IECC) and local building codes that set minimum insulation requirements.

- Stay informed about updates and revisions to energy efficiency standards.

- Calculate insulation R-values and design insulation systems to meet code requirements.

- Work with architects and engineers to ensure compliance with energy efficiency regulations.

10. How do you determine the most cost-effective insulation solution for a particular building project?

- Evaluate Building Factors: Consider climate, building size, and energy consumption patterns.

- Compare Insulation Options: Research different insulation materials, their R-values, and installation costs.

- Calculate Energy Savings: Estimate potential energy savings and cost reductions based on different insulation options.

- Consider Long-Term Value: Factor in the durability, maintenance costs, and environmental impact of different insulation materials.

- Consult Industry Experts: Seek advice from insulation manufacturers, contractors, or energy auditors to optimize the solution.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Insulation Professional.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Insulation Professional‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Insulation Professionals play a crucial role in construction projects, ensuring the proper installation of insulation materials to enhance energy efficiency and thermal comfort.

1. Installation and Inspection

Primary tasks involve installing Insulation materials, such as fiberglass, cellulose, or foam, in various building components like walls, ceilings, and attics.

- Follow building codes and manufacturers’ specifications for insulation installation.

- Inspect Insulation materials for damages or defects before installation.

2. Material Handling and Transportation

Handling and transporting Insulation materials require proper techniques to ensure they are not damaged or compromised.

- Load and unload Insulation materials safely using appropriate equipment.

- Follow storage guidelines to maintain the integrity and quality of Insulation materials.

3. Job Site Safety

Insulation Professionals work in construction sites, which can pose potential hazards.

- Adhere to safety regulations and wear appropriate protective gear, such as respirators and gloves.

- Identify and mitigate potential hazards on the job site, such as electrical wires or sharp objects.

4. Teamwork and Collaboration

Insulation Professionals often work alongside other construction professionals, such as electricians and carpenters.

- Collaborate with other trades to ensure smooth workflow and prevent conflicts.

- Communicate effectively with supervisors, colleagues, and clients to meet project goals.

Interview Tips

Preparing thoroughly for an Insulation Professional interview can significantly improve your chances of success. Here are some key tips to help you ace the interview:

1. Research the Company and Industry

Familiarize yourself with the company’s history, culture, and specific projects related to Insulation.

- Visit the company’s website and social media pages.

- Read industry publications and articles to stay updated on the latest advancements in Insulation.

2. Practice Your Answers

Prepare responses to common interview questions, such as “Why are you interested in Insulation?” and “Describe your experience with Insulation materials.”

- Use the STAR method (Situation, Task, Action, Result) to structure your answers.

- Highlight your skills, experience, and achievements that are relevant to the position.

3. Dress Professionally and Arrive on Time

First impressions matter, so dress appropriately for the interview and arrive on time.

- Wear business attire, such as a suit or dress pants and a button-down shirt.

- Plan your route in advance to avoid any delays or getting lost.

4. Be Enthusiastic and Ask Questions

Show your passion for Insulation and ask thoughtful questions to demonstrate your interest and knowledge.

- Prepare questions about the company’s Insulation practices and the specific role you are interviewing for.

- Be enthusiastic and engage with the interviewer, making eye contact and actively listening.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Insulation Professional interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!